Troubleshooting, Replacing pulleys and belts, Bearing replacement – COOK IMH User Manual

Page 7

7

e. Remove burrs from shaft by sanding.

f. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their

respective shafts.

g. Tighten in place.

h. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Speed Reduction

Open the pulley in order that the belt rides deeper in

the groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in

the groove (larger pitch diameter). Ensure that the

RPM limits of the fan and the horsepower limits of the

motor are maintained.

Replacing Pulleys and Belts

a. Remove pulleys from their respective shafts.

b. Clean the motor and fan shafts.

c. Clean bores of pulleys and coat the bores with heavy

oil.

d. Remove grease, rust, or burrs from the pulleys and

shafts.

e. Remove burrs from shaft by sanding.

f. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their

respective shafts.

g. Tighten in place.

h. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Bearing Replacement

The fan bearings are pillow block ball bearings.

An emery cloth or file may be needed to remove imper-

fections in the shaft left by the setscrews.

a. Mark the position on the shaft of both bearing races,

setscrews, and the wheel and pulley. Note the clear-

ance between the wheel and inlet.

b. Remove the fan pulley and belts.

c. Remove the inlet side panel by removing the bolts

around the perimeter of panel.

d. Remove inlet cone by removing attaching bolts/nuts

around perimeter of the inlet plate.

e. Remove wheel from the shaft. A 2-jaw puller may be

needed.

f. Remove bearing hold-down bolts. Remove shaft and

bearings as one unit.g. Remove the anti-corrosion

coating from the shaft with a suitable degreaser.

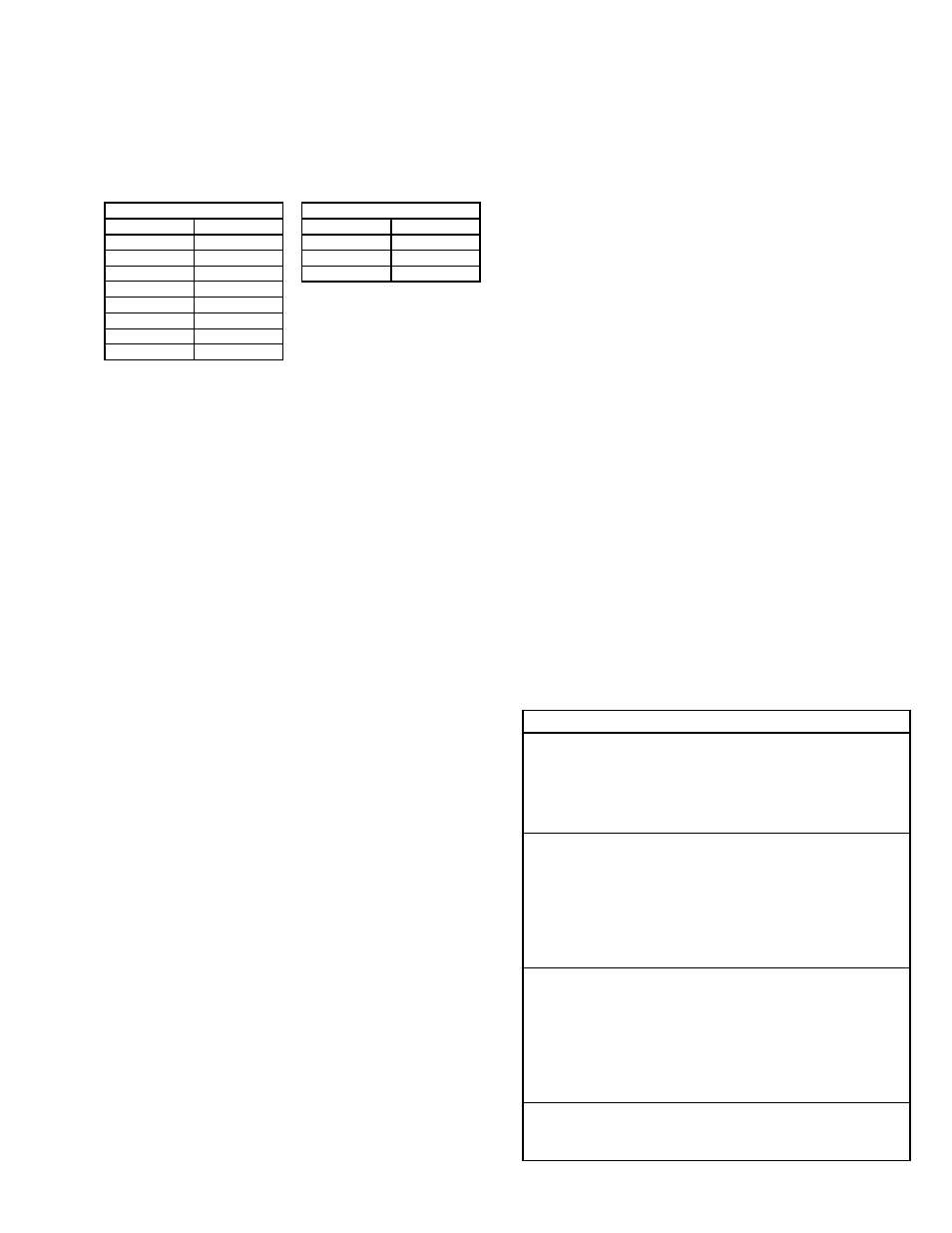

RPM Derating Factor

For elevated airstream temperatures, the maximum RPM limits must be derated

by the factors found in the RPM Derating Factor table above.

Steel

Aluminum

Temp. °F

RPM

Temp. °F

RPM

70

1.00

70

1.00

200

.98

200

0.93

300

.96

300

0.79

400

.94

500

.91

600

.87

700

.81

800

.75

h. Remove the bearing from the shaft using a bearing

puller. If a bearing puller is not available, tap on the

bearing with a wood block and hammer to remove it.

i. Smooth and clean the shaft and bearing bore thor-

oughly.

j. Place the bearings into position making sure they are

not on a worn section of the shaft. Tapping the inner

ring face with a soft driver may be required.

Do not hammer on the housing.

k. The outer ring of the bearing is spherical and swivels

in the housing to compensate for misalignment.

Secure hold-down bolts, but do not fully tighten.

l. Align the setscrews on the bearings and tighten one

setscrew on each bearing.

m. Rotate the shaft to allow the bearing outer rings to

find their center of free movement.

n. Install the wheel on the shaft and install the inlet side

panel in its original location. Adjust bearing position

and inlet side panel to center the wheel in the inlet.

o. Tighten bearing hold-down bolts to proper torque.

Refer to Torque Chart.

p. Turn the shaft by hand. Resistance should be the

same as it was before hold-down bolts were fully tight-

ened.

q. Tighten bearing setscrews to specified torque as

noted in the Torque Chart.

r. Reinstall the pulley and adjust the belt tension. Refer

to Belt and Pulley Installation.

s. Test run the fan and trim balance as necessary (.0785

in/sec max.).

t. Re-tighten setscrews on bearings, sheave, and wheel.

Recheck belt tension and adjust as needed.

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the fan rotates in same

direction as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at

the inlet.

•Improper wheel alignment.

Excessive Vibration and Noise

•Damaged or unbalanced wheel.

•Belts too loose; worn or oily belts.

•Speed too high.

•Incorrect direction of rotation. Make sure the fan rotates in same

direction as the arrows on the motor or belt drive assembly.

•Bearings need lubrication or replacement.

•Fan surge or inlet or outlet conditions.

Overheated Motor

•Motor improperly wired.

•Incorrect direction of rotation. Make sure the fan rotates in same

direction as the arrows on the motor or belt drive assembly.

•Cooling air diverted or blocked.

•Improper inlet clearance.

•Incorrect fan RPMs.

•Incorrect voltage.

Overheated Bearings

•Improper bearing lubrication

•Excessive belt tension.