Duct installation – COOK IMH User Manual

Page 2

2

Duct Installation

Efficient fan performance relies on the proper installation

of inlet and discharge ducts. Be sure your fan conforms to

the guidelines below.

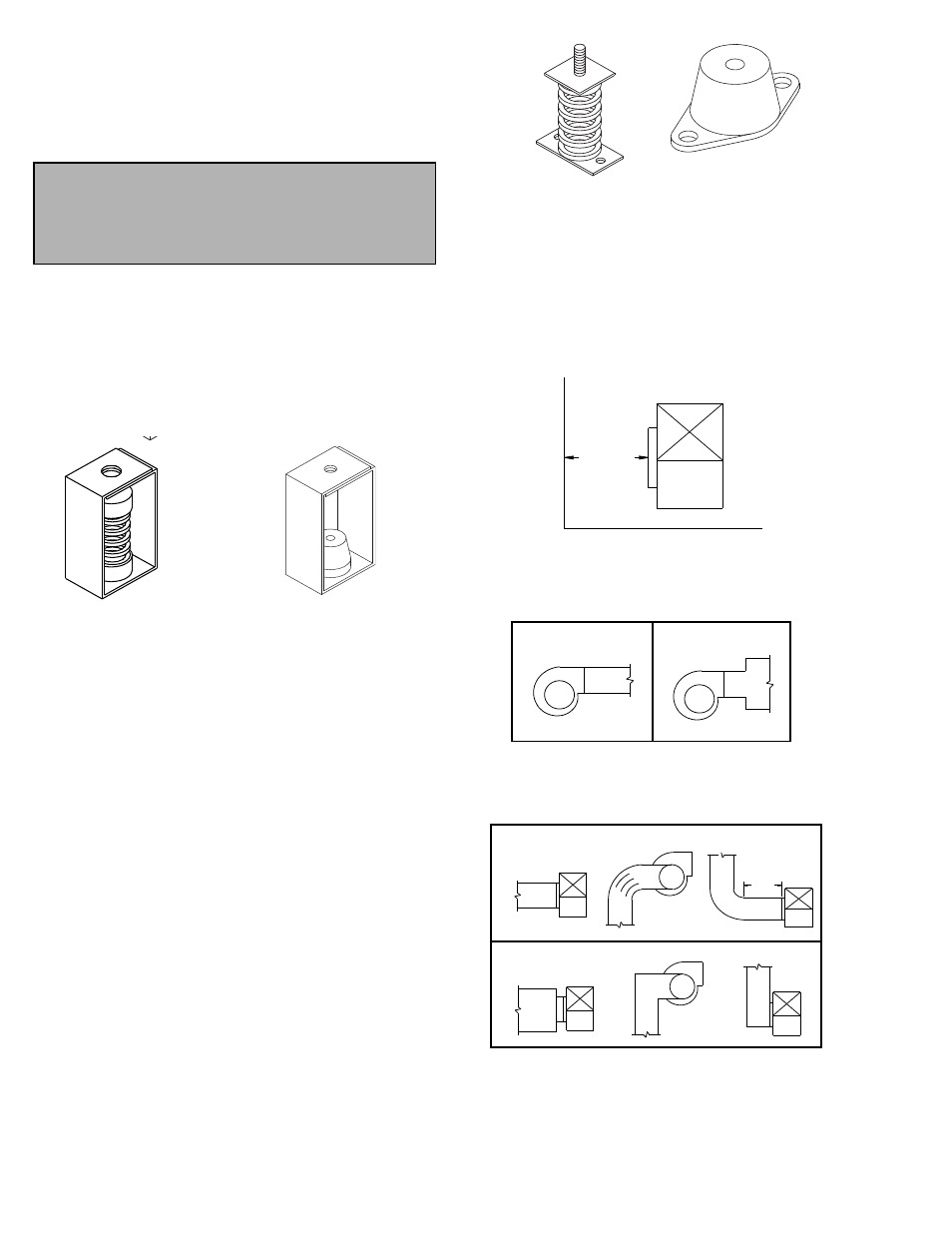

Non-Ducted Inlet Clearance

If your fan has an open inlet (no duct work), the fan must

be placed 1 fan wheel diameter away from walls and bulk-

heads. An inlet bell should be used in this case.

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost efficiency because it doesn’t allow for a static regain.

Inlet Duct Turns

For ducted inlets, allow at least 3 fan wheel diameters

between duct turns or elbows and the fan inlet.

Discharge Duct Turns

Make sure that duct turns located near the fan discharge

curve in the direction of the fan’s rotation. Refer to the Dis-

charge Duct Turns illustration on page 3.

Figure 2 -Floor Mount Isolators

Rubber-In-Shear Isolator

Spring Isolator

Non-ducted Inlet Clearance

MIN 1 DIA

Correct

Incorrect

Free Discharge

Correct

Incorrect

Inlet Duct Turns

MIN 3

DIA

distortion which can lead to excessive belt and bearing

wear; its perimeter should contain all base angles and

rotating parts. Arrangement 10 fans above size 270 require

isolation rails. Please consult factory for isolation of

arrangement 9 fans due to the potential of uneven loading

caused by the motor and drives. Isolators should be

located between the fan system and the support structure.

Ceiling Mounted Isolators

Some applications require fan systems, designed for

floor mounting, suspended from ceiling supports. In such

cases, IMH fans of all arrangements should be installed on

either rails or bases in the classical orientation. Typically,

these systems are hung from the corners by rods, which

include isolation hangers of either spring or rubber-in-shear

design. Under no circumstances is the fan to be

inverted and hung by its base angles.

Floor Mounted Spring Isolators

a. Mount fan and motor on isolation base (if supplied).

b. Elevate fan (or isolation base) to operating height and

insert blocks to hold in position.

c. Position isolators under the fan (or isolation base) and

vertically align by inserting leveling bolt through

mounting holes in the fan or the base. The isolator

must be installed on a level surface.

d. Adjust the isolators by turning the leveling nut counter

clockwise several turns at a time alternately on each

isolator until the fan weight is transferred onto the iso-

lators and the fan raises uniformly off the blocks. Then

remove the blocks.

e. Turn lock nut onto leveling bolt and secure firmly in

place against the top of the mounting flange or frame.

f. Secure isolators to mounting surface.

Floor Mounted Rubber-In-Shear (RIS) Isolators

a. Mount fan and motor on an isolation base (if supplied).

b. Elevate fan to provide room to insert isolators

between the fan and foundation and block in position.

c. Position isolators under fan and secure bolts.

d. Remove blocks and allow fan to rest on floor. Isolators

must be installed on a level surface (leveling should

not be required).

e. Secure isolators to mounting surface.

Note

Although a certain amount of vibration is inherent in

operating centrifugal fans, extreme vibration is a seri-

ous problem that may cause structural and mechani-

cal failure.

Ceiling Mounted Spring Isolator

Rubber-in-Shear Ceiling Isolator

Figure 1- Ceiling Mount Isolators