Operation – COOK ERV User Manual

Page 9

9

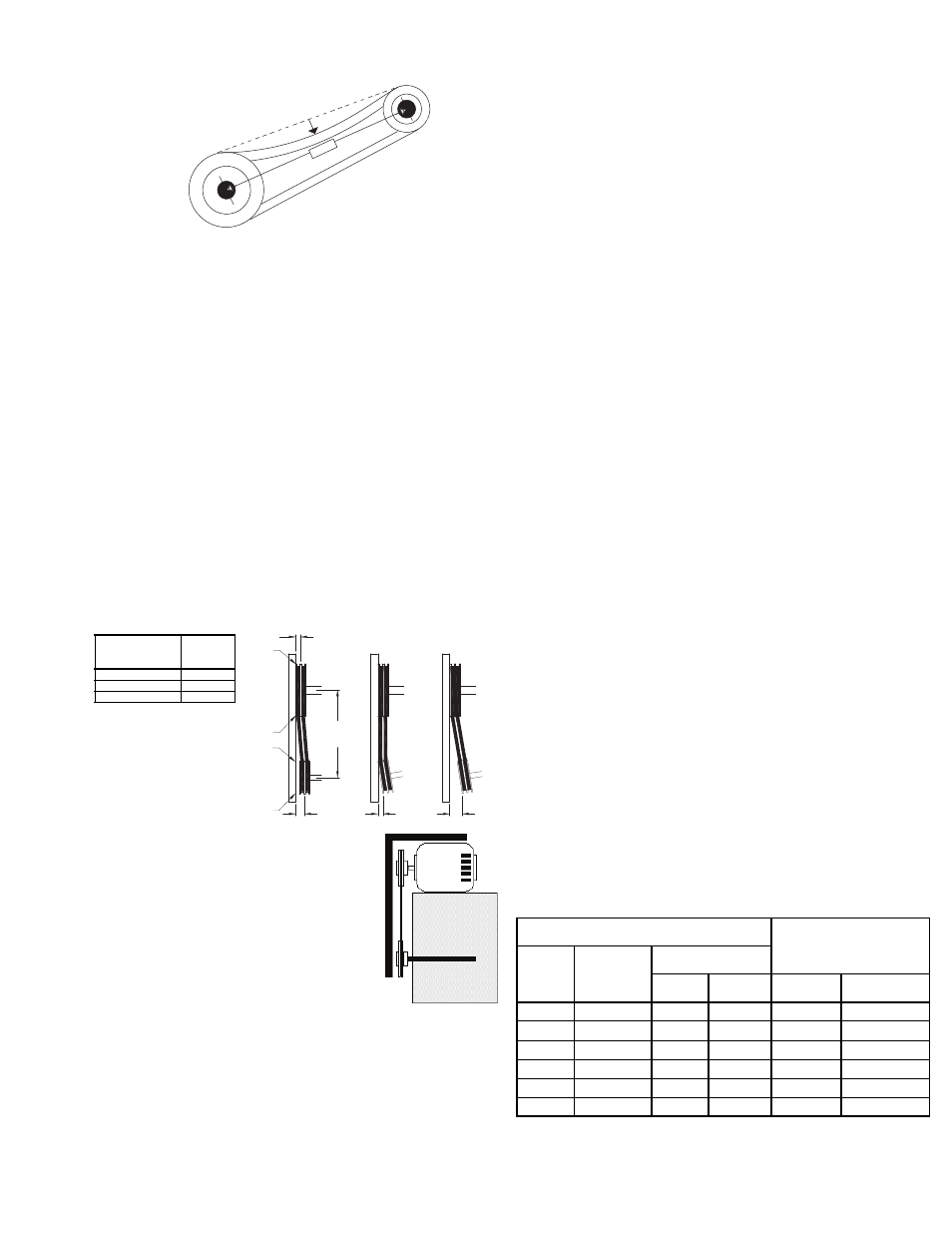

1 foot

1/4 inch

Belt and Pulley Installation

Belt tension is determined by the sound the belts make

when the fan is first started. Belts will produce a loud squeal

which dissipates after the fan is operating at full capacity. If

the belt tension is too tight or too loose, lost efficiency and

possible damage can occur.

Do not change the pulley pitch diameter to change ten-

sion. This will result in a different fan speed than desired.

a. Loosen motor plate adjustment screw and move motor

plate in order that the belts can easily slip into the

grooves on the pulleys. Never pry, roll, or force the

belts over the rim of the pulley.

b. Slide the motor plate back until proper tension is

reached. For proper tension a deflection of approxi-

mately 1/4” per foot of center distance should be

obtained by firmly pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment nuts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 2.

Pulley Alignment

Pulley alignment is

adjusted by loosening

the motor pulley set-

screw and by moving the

motor pulley on the motor shaft.

Figure 2 indicates where to measure the

allowable gap for the drive alignment toler-

ance. All contact points (indicated by

WXYZ) are to have a gap less than the tol-

erance shown in the table. When the pul-

leys are not the same width, the allowable

gap must be adjusted by half of the differ-

ence in width (As shown in A & B of Figure

2). Figure 3 illustrates using a carpenter’s

square to adjust the position of the motor pulley until the

belt is parallel to the longer leg of the square.

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten accord-

ing to the recommended torque shown in the table

Recommended Torque for Setscrews/Bolts.

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

d. If applicable, ensure fan is secured to ductwork.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power

sources.

b. Ensure fasteners and setscrews, particularly those

used for mounting the fan, are tightened.

c. Inspect belt tension and pulley alignment on blowers.

d. Inspect belt tension on energy wheel drive belt.

e. Inspect motor wiring.

f. Ensure belt touches only the pulleys.

g. Ensure fan and ductwork are clean and free of debris.

h.Ensure rotor moves freely by hand. If not, recheck the

seal to determine whether or not it is binding and if so

adjust seals following the sealcheck instructions.

i. Ensure motor rotation is correct by detaching the belts

from the drive sheave and bumping the motor. The

sheave should be rotating in the direction such that the

belt will result in rotation per the exterior markings. If

not, rewire the motor.

j. Ensure the air flow orientation matches up to design by

looking at the identification markings on the cassette

and/or refer to the general arrangement drawing to

check the four duct connections to the unit.

k. Close and secure all access doors.

l. Restore power to the fan.

Changing Fan Speed

The motor/blower combinations on ERV sizes 1500 and

up are equipped with variable pitch pulleys. To change the

fan speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in

the groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits

of the fan and the horsepower limits of the motor are main-

tained.

Figure 2

Figure 3

Figure 1

OFFSET

ANGULAR

OFFSET/ANGULAR

A

W

X

Y

Z

B

CENTER

DISTANCE

(CD)

GAP

GAP

Tolerance

Center Distance

Maximum

Gap

Up thru 12”

1/16”

12” up through 48

1/8”

Over 48”

1/4”

Recommended Torque for Setscrews/Bolts (IN/Lb)

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”- 9

2040

1/2”

1/4”

504

600

1”- 8

3000