COOK ERV User Manual

Page 8

8

Mounting

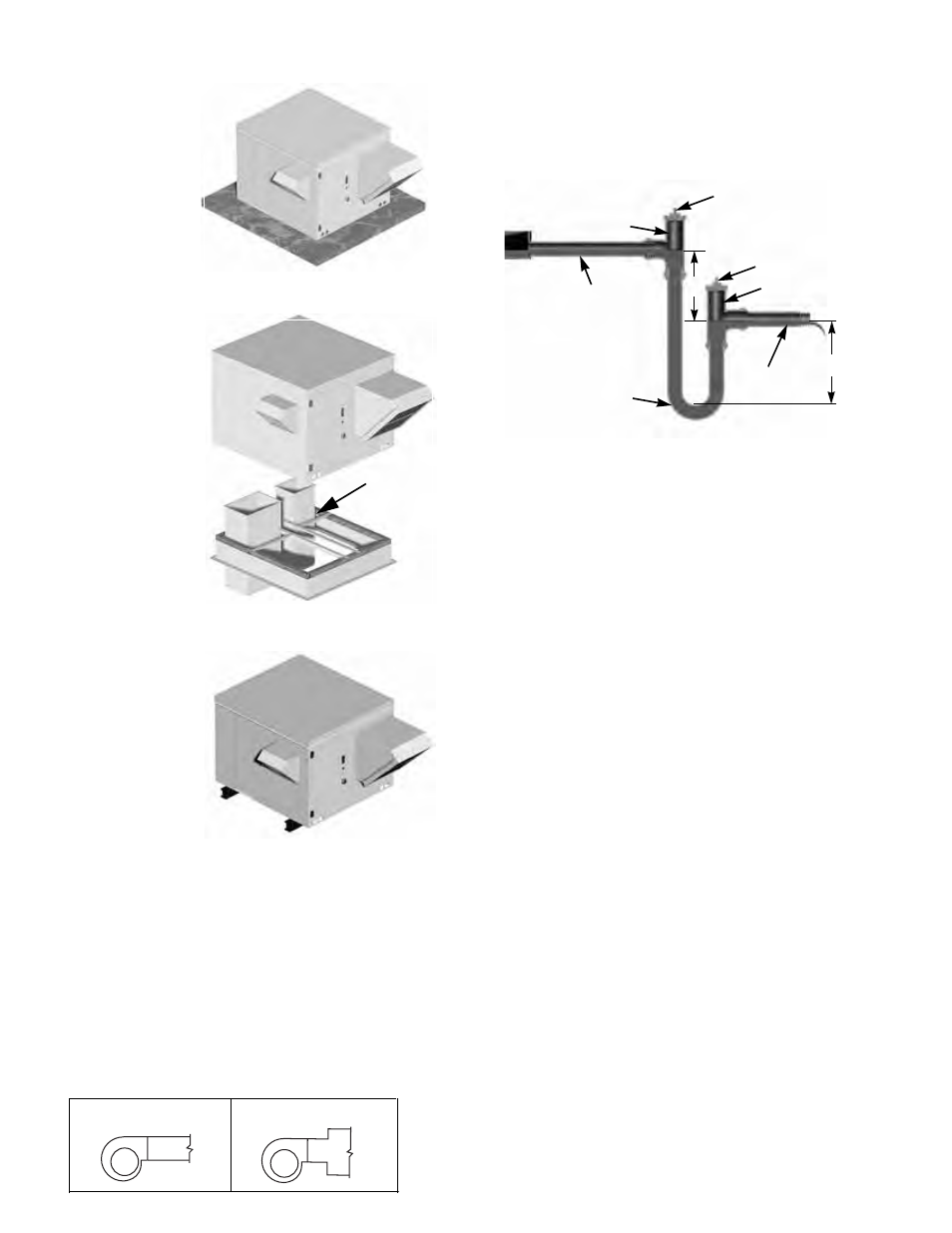

Foundation Mounting for Arrangement H

The ERV requires a

strong, level foundation

of reinforced poured

concrete. A correctly

designed concrete

foundation provides the

best means for mount-

ing floor units. The size

of the foundation is

determined by unit size

and the specific location

of the installation. The

use of rubber isolation

pads between the unit

base and the foundation

is recommended.

Use the following

guidelines to calculate

foundation size:

• The overall dimen-

sions of the foundation

should extend at least

six inches beyond the

outline of the unit.

• The weight of the

foundation should be

two to three times the

weight of the unit and its

motor.

Rail Mounting

Use the following recom-

mendations when

designing for rail mount-

ing:

• Rails should be posi-

tioned six to twelve

inches in from sides of

the unit.

• Rails should extend a

minimum of six inches

beyond the sides of the

unit.

Ductwork Connections

Discharge Duct Turns

Where possible, allow 3 duct diameters between duct turns

or elbows and the fan outlet. Refer to the figure below.

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost efficiency because it doesn’t allow for a static regain.

Refer to figure below.

Installation of Condensate Drain Pan Traps

All drain and trap piping should be sized to match the con-

densate drain pan pipe connection supplied on cooling coil

equipped ERV’s. The below figure shows the correct lay-

out of a low maintenance, trouble-free condensate drain

pan trap. Finger tight plugs allow easy access for inspec-

tion and cleaning. To prevent an air leak into the unit

through the trap, dimensions “A” and “B” should be double

the total static pressure “head” found in the drain pan com-

partment.

Motor Installation

To prevent damage to the unit during shipping, extremely

heavy motors (cast iron or severe duty) are shipped loose

and must be field mounted by bolting the motor on the

motor mounting plate in the existing mounting slots.

The motor has been prewired to turn the proper direction.

Follow the directions on the motor schematic accompany-

ing the motor. Some motors can accommodate either 220V

or 440V operation. Once the motors are wired, test run the

ERV and check for proper rotation.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor name-

plate.

Lock off all power sources before unit is wired to

power source.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connec-

tion with the terminal box at the end of the motor. To

remove motor, remove bolts securing motor base to power

assembly. Do not remove motor mounting bolts.

Follow the wiring diagram in the disconnect switch

and the wiring diagram provided with the motor. Cor-

rectly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

Do not allow the fan to run in the wrong direction.

This will overheat the motor and cause serious dam-

age. For 3-phase motors, if the fan is running in the

wrong direction, check the control switch. It is possi-

ble to interchange two leads at this location so that the

fan is operating in the correct direction.

Clean Out

ERV Condensate

Drain Pipe

Finger-Tight Plug

Finger-Tight Plug

Clean Out

Slope To Drain

(6” Min)

B

(6” Min)

A

Drain Trap

Curb Mounting

Ductwork

Mounting

Rails

Rail Mounting

Foundation Mounting for Arr. H

Correct

Incorrect