Bearings, Motor services, Troubleshooting – COOK Economizer Fan User Manual

Page 5: Filters, Motor bearings

Clean the propeller and air inlets if material build-up is

excessive. Excessive build-up can cause imbalance and

failure of the propeller. When cleaning the propeller, always

clean the entire propeller. Partial cleaning will cause imbal-

ance and will lead to unit failure.

Filters

Filters should be checked within the first two weeks of

operation. If there is no excessive build-up, monthly servic-

ing should be adequate.

To clean reusable aluminum filters, back flush with soap

and water. When clean, shake off excess water and allow

the filter to air-dry before reinstalling it.

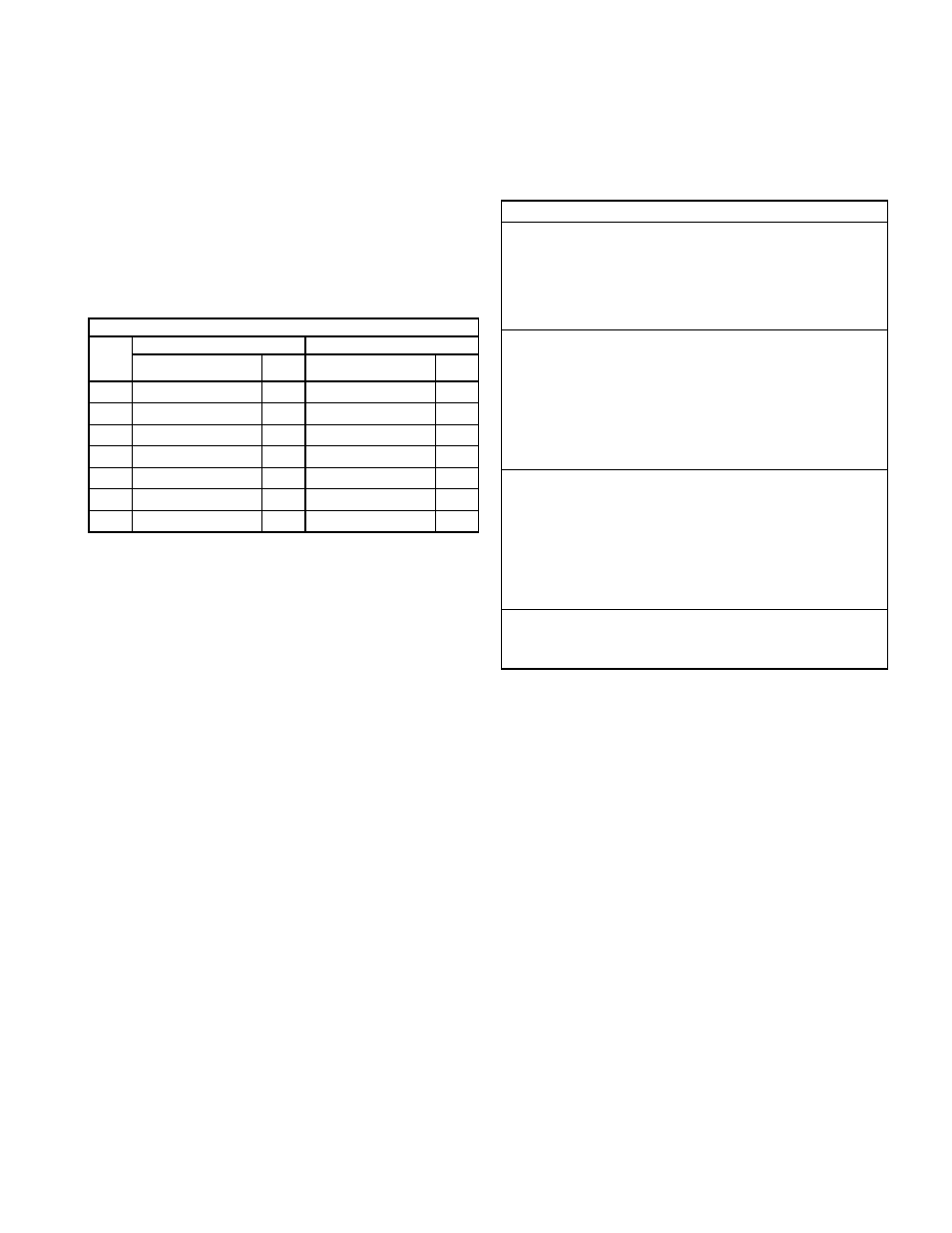

Please note the following tables concerning filter sizes.

Motor Bearings

Motor bearings are pre-lubricated and sealed. Under

normal conditions they will not require further maintenance

for a period of ten years. However, it is advisable to have

your maintenance department remove and disassemble

the motor, and lubricate the bearings after three years of

operation in excessive heat and or in a contaminated air-

stream consisting of airborne abrasives.

Economizer Fan Filter Sizes

Unit

Type 1

Type 2

Size

Length x Width

No.

Req’d

Length x Width

No.

Req’d

24

18-1/4” x 30-1/8”

2

18-1/4” x 33-1/4”

4

30

20-7/16” x 18-1/16”

4

20-7/16” x 25-13/16”

6

36

22-1/4” x 21-1/16”

4

22-1/4” x 29-5/32

6

42

24-1/16” x 29-1/2”

4

26-7/8” x 19-1/4”

6

48

27” x 27”

4

27” x 27”

8

54

29-1/8” x 19-3/8”

6

29-1/8” x 23-5/8”

10

60

37-7/8” x 21-7/8

6

26” x 28-9/16”

10

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook Company represen-

tative or your nearest authorized electric motor service rep-

resentative.

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at the

inlet.

•Improper propeller alignment.

Excessive Vibration and Noise

•Damaged or unbalanced propeller.

•Belts too loose; worn or oily belts.

•Speed too high.

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Bearings need lubrication or replacement.

•Fan surge.

Overheated Motor

•Motor improperly wired.

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Cooling air diverted or blocked.

•Improper inlet clearance.

•Incorrect fan RPMs.

•Incorrect voltage.

Overheated Bearings

•Improper bearing lubrication

•Excessive belt tension.

5