Final installation, Operation, Maintenance – COOK Economizer Fan User Manual

Page 4: Start-up, Inspection, Final installation steps, Modes

light will begin to flash. If the mode light is allowed to flash

for the full 3 seconds, the light will then stay on and the fan

will start.

If the panel contains a temperature controller, this mod-

ule will be powered only during mix mode. The display on

the temperature controller indicates the outlet temperature

of the fan and the set value which it is trying to produce by

mixing outside air and inside air. The set value temperature

must be between the indoor and outdoor temperatures in

order for the fan to match the set value. Refer to the Control

Panel for programming instructions to set the value temper-

ature.

If the operating mode is changed, such that the direction

of the propeller rotation must change, there will be a 30

second spin down delay before the start of the new mode.

Start-Up

Turn fan on in supply mode. Inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble. Refer to

Troubleshooting,

page 5

.

Inspection

Inspection of the fan should be conducted at the first

30

minute, 8 hour

and

24 hour

intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as

instructed.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

24 Hour Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

Maintenance

Establish a schedule for inspecting all rotating parts. The

frequency of inspection depends on the operating condi-

tions and location of the fan.

Inspect fans exhausting corrosive air within the first

month of operation.

Yearly inspections are recommended for fans exhausting

non-contaminated air.

It is recommended that inspection of the unit be con-

ducted twice annually.

• Inspect bolts and setscrews for tightness. Tighten as

necessary. Refer to

Torque chart

.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease build-up on motor housing

assures proper motor cooling.

Final Installation Steps

a. Check and tighten fasteners and setscrews, particu-

larly unit mounting fasteners. Tighten according to the

recommended torque shown in table

Recommended

Torque for Setscrews/Bolts

..

b. Check for correct voltage with voltmeter.

c. Ensure all accessories are installed.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Check and tighten fasteners and setscrews, particu-

larly those used for mounting the unit.

c. Check motor wiring.

d. Rotate the prop to ensure it does not rub against the

venturi.

e. Ensure fan and ductwork are clean and free of debris.

f. Close and secure all access doors.

g. Restore power to unit.

There are four basic designs for the operation control

panel on this unit. They are defined by whether or not the

fan unit is reversible, and whether or not the mix mode is

supplied with a temperature control and modulating damp-

ers.

Modes

MRS-D

- mix, recirculate, supply.

MRS-D with Modulating Temperature Controller

- mix

dependent upon fan outlet temperature, recirculate, supply.

MRSE-D

- mix, recirculate, supply, exhaust.

MRSE-D with Modulating Temperature Controller

-

mix dependent upon fan outlet temperature, recirculate,

supply, exhaust.

The function pad on the front of the control panel con-

tains two operators - a

Start/Mode

button and a

Stop

but-

ton.

When the Start/Mode button is depressed, the top mode

light will start to flash. This light will flash for 3 seconds to

indicate that a mode is ready to begin. If the mode button is

pressed again within the 3 second delay, the next mode

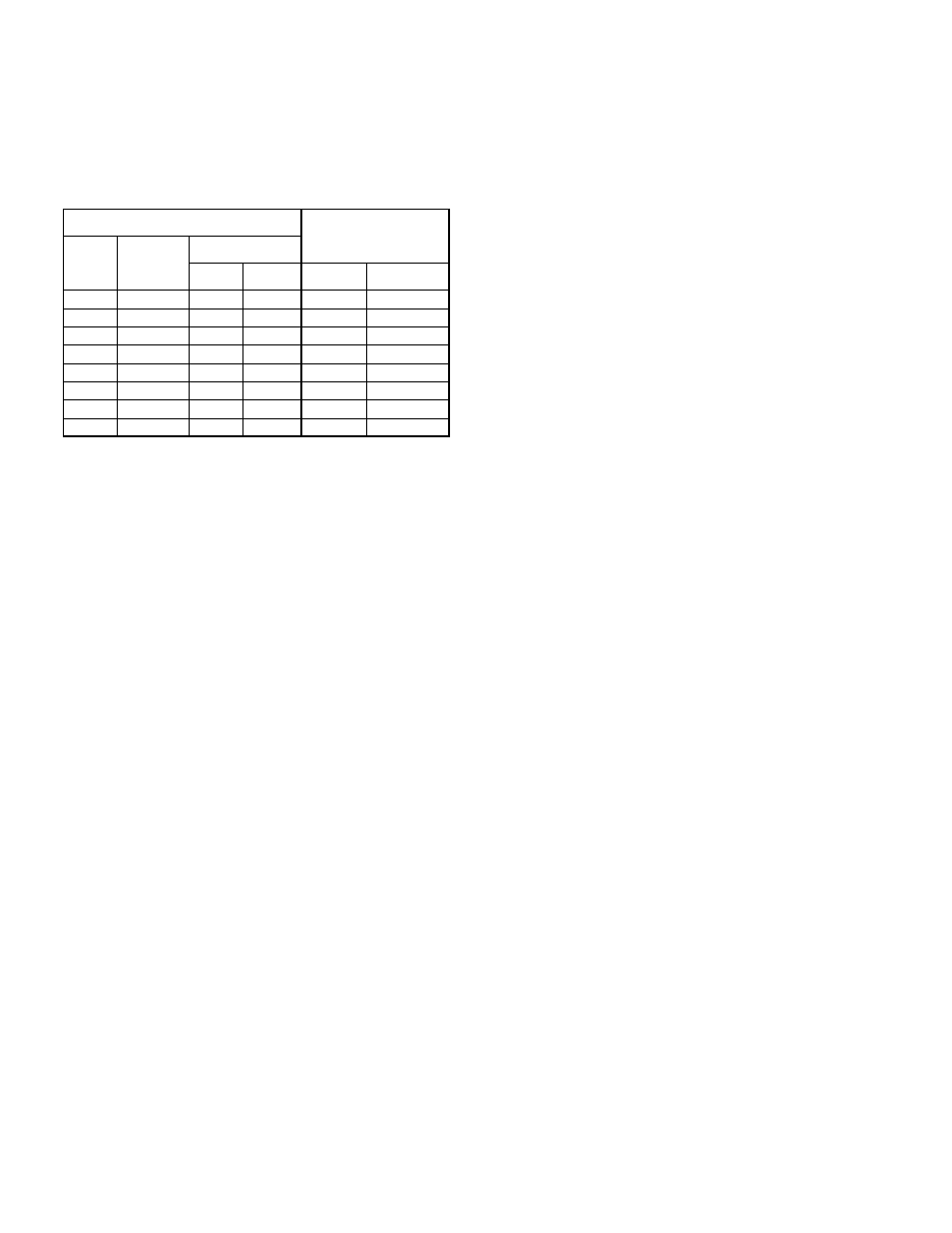

Recommended Torque for Setscrews/Bolts

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”-9

2040

1/2”

1/4”

504

600

1”-8

3000

5/8”

5/16”

1104

1200

1-1/8”-7

4200

3/4”

3/8”

1440

1800

1-1/4”-7

6000

4