Swiftech MCW6000 NX User Manual

Page 2

2.

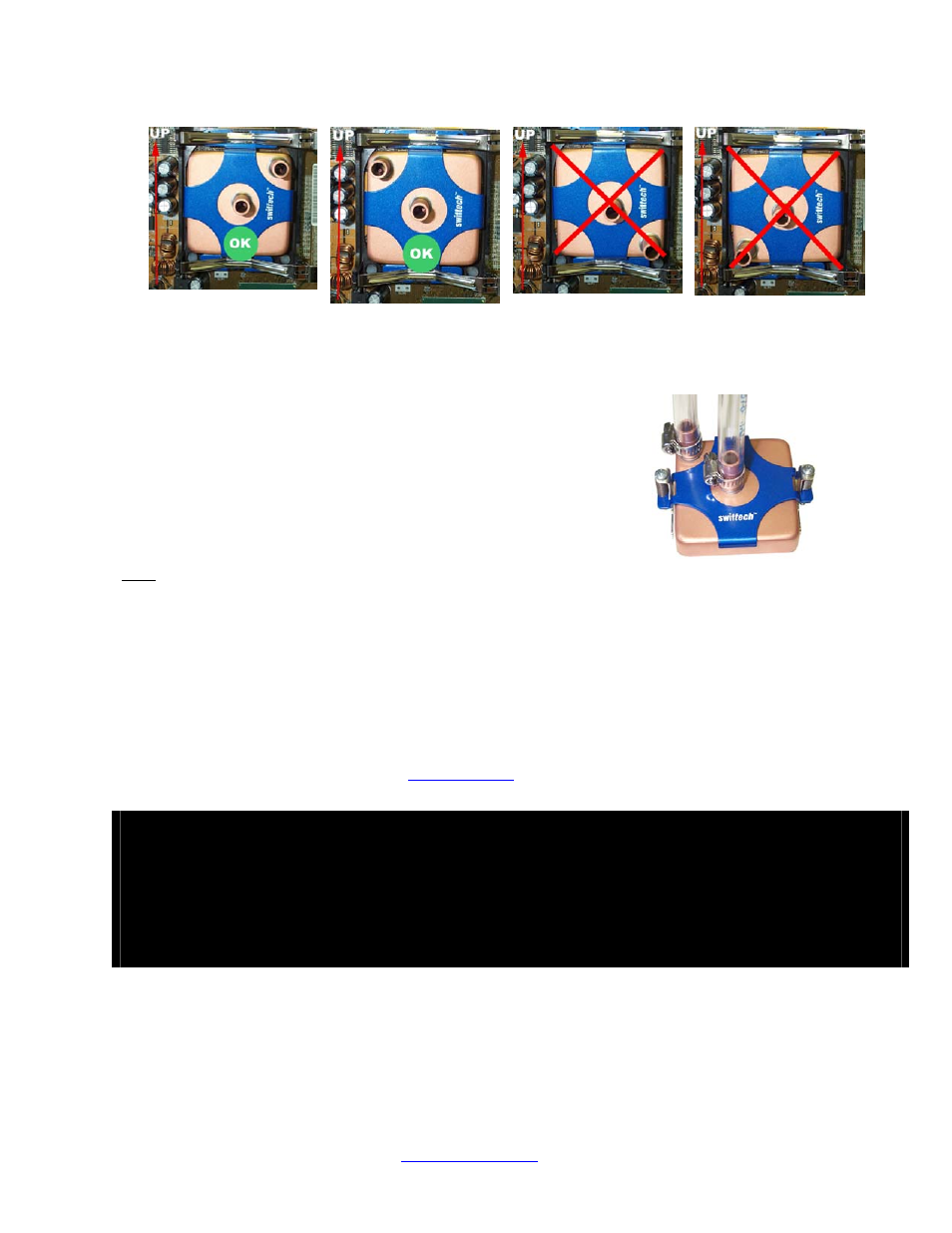

Water-block orientation

For ease of operations during the filling and bleeding procedures, the outlet should always be at the highest point (while the

computer system is standing upright):

3. Water-block

installation

The MCW6000-NX water-block uses Intel’s validated retention spring, provided in accordance to Intel specifications by the

motherboard vendors. Installation of the water-block to the processor is identical to that of a standard heatsink, normally

described in the motherboard installation guide. Simply screw down all 4 Philips screws to the chassis standoffs as shown in

Figure 1, and installation is complete.

Figure 2

Tubes attached with the included

worm-drive clamps

4.

Connecting the water-block(s) to the cooling circuit:

Carefully identify the direction of the flow in your circuit. For the MCW6000 to operate

properly, the fitting located at the center of the water-block MUST BE USED AS THE

INLET. In multi-processor environments, connect the two blocks in series: For example:

from pump discharge to inlet of processor 1, discharge of processor 1 to inlet of processor 2,

and discharge of processor 2 to radiator.

5.

Attaching the tubes:

When sold separately, the MCW6000™ ships with worm-drive type hose clamps. Secure the

tubes as shown in figure 2 (shown in this example with an AMD hold-down plate), and tighten

firmly. When sold in kits, the tubes are factory pre-installed with ear-clamps.

6. Type

of

Coolant:

Being entirely made of copper, the MCW6000™ may be used with pure water, and does not

necessitate the use of anti-corrosion agents. The use of an algaecide is nonetheless

recommended in any liquid cooling system, and our HydrX™ additive also performs such

function.

7. Final

inspection

Once the installation is completed, it is always a good idea to test the circuit for leaks, prior to

powering up the computer. Do not test the water-block using city water pressure. This

will bow the top of the housing and render the block unusable (and will void your warranty).

Maximum pressure allowable for testing is 25 psi (1.7 bar)

Troubleshooting help is available on our

, or by calling

customer support at 562-595-8009.

IMPORTANT DISCLOSURES

While all efforts have been made to provide the most comprehensive tutorial possible, Swiftech assumes no liability expressed or implied for

any damage(s) occurring to your components as a result of using Swiftech cooling products, either due to mistake or omission on our part in

the above instructions, or due to failure or defect in the Swiftech cooling products.

WARRANTY

Our products are guaranteed for 12 months from the date of delivery to the final user against defects in materials or workmanship. During this

period, they will be repaired or have parts replaced provided that: (I) the product is returned to the agent from which it was purchased; (II) the

product has been purchased by the end user and not used for hire purposes; (III) the product has not been misused, handled carelessly, or

other than in accordance with any instructions provided with respect to its use. This guarantee does not confer rights other than those

expressly set out above and does not cover any claims for consequential loss or damage. This guarantee is offered as an extra benefit and

does not affect your statutory rights as a consumer.

Copyright Swiftech 2004 – All rights reserved – Last revision date: 11-23-04

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-

8769 - E Mail: [email protected] – URL:

http://www.swiftnets.com

- Information subject to change without notice

Page 2 of 2