Installation – Blodgett SBC-G Series User Manual

Page 7

OM-SBC-G 5

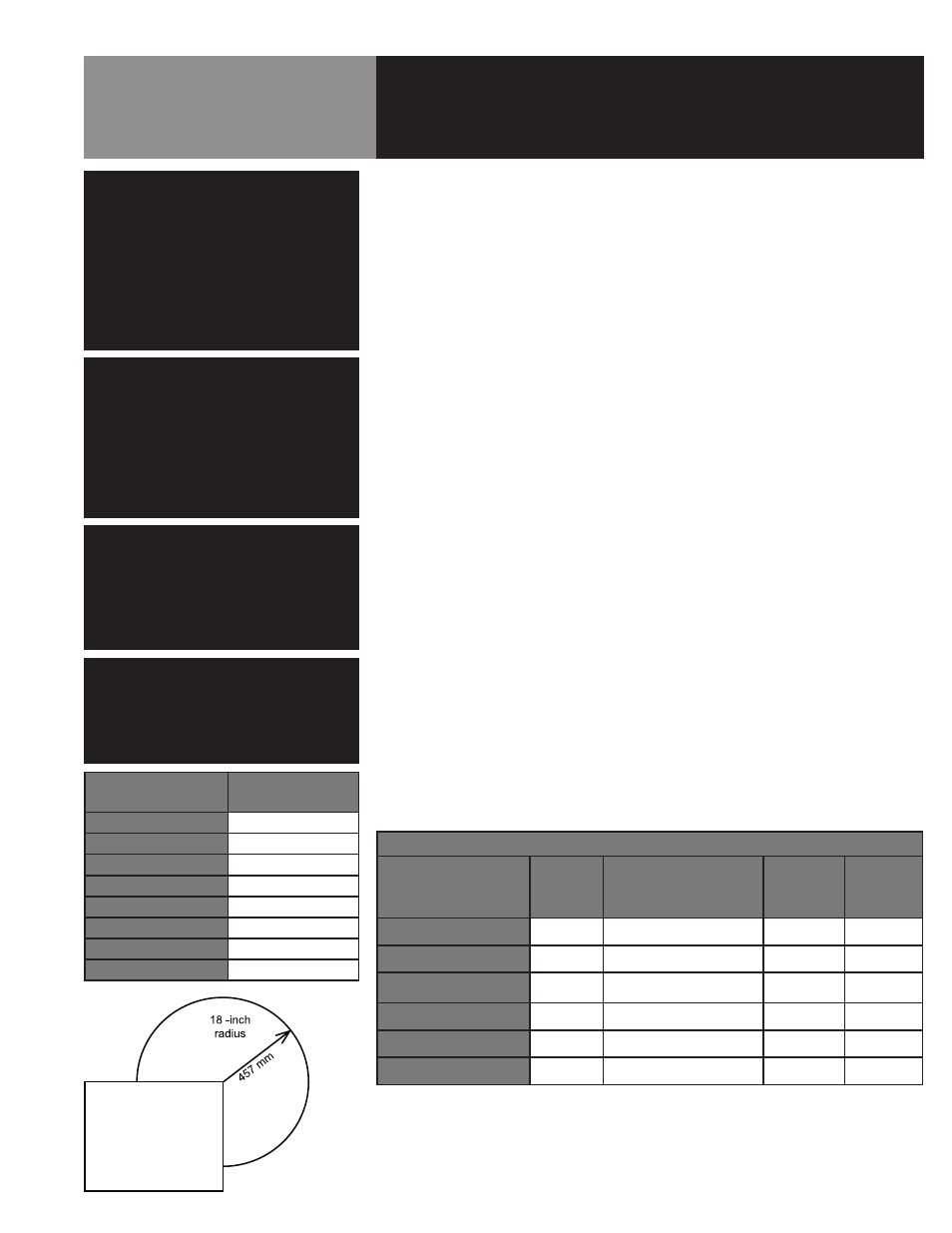

Minimum Clearances: Boilerless steamer requires the following minimum clearances

to any surface, combustible or noncombustible.

Right Side

2 inches

Left Side

2 inches

Rear

6 inches

Steam Free Zone: The boilerless steamer can be damaged by steam from external

sources. Do not install the steamer over a steam venting drain. Ensure that steam is

not present in an area bounded by the footprint of the steamer and a circle 18 inches

in radius about the right rear corner of the steamer (see figure at left).

Install and operate the gas appliance in a well ventilated area. Adequate air must be

supplied to replenish the air used for combustion. Installation must conform with local

codes and/or with the National Fuel Gas Code, ANSI Z223.1/NFPA-54 (latest edition) or

the National Gas and Propane Code CSA B149.1 as applicable.

Any item which might obstruct or restrict the flow of air for combustion and ventilation

must be removed. Do not obstruct the flue cover or rear vents after installation.

The steamer must be disconnected from the gas supply system during any pressure

testing of that system which has test pressures in excess of 1/2 PSI (3.45 kPa).

1. Electrical Supply Connection

Provide 115 VAC, 60 HZ, 1 PH, 15 AMP service. Bring wire in through hole in the

lower left back panel. Each cavity requires a separate cord for connections. Local

codes and/or the National Electrical Code should be observed in accordance with

ANSI/NFPA 70. AN ELECTRICAL GROUND IS REQUIRED. The wiring diagram is

located in the service compartment and in this manual. Maximum load is 21/2

AMPs. In Canada, provide electrical service in accordance with the Canadian

Electrical Code, CSA C22.2 Part 1 and/or local codes.

2. Gas Supply Connection

Connection to the gas supply shall be in accordance with the chart at left.

After the unit has been connected to the gas supply, all gas joints must be

checked for leaks. Do NOT use flame checking for leaks. A thick soap solution or

other suitable leak detector should be used.

CAUTION

DO NOT INSTALL THE UNIT WITH THE REAR

VENTS BLOCKED OR WITHIN 2 INCHES

OF A HEAT SOURCE SUCH AS A BRAISING

PAN, DEEP FAT FRYER, CHARBROILER OR

KETTLE. TO AVOID DRAINAGE PROBLEMS,

LEVEL THE UNIT FRONT TO BACK, AND

PITCH SLIGHTLY TO THE FRONT.

Installation

WARNING

THE UNIT MUST BE INSTALLED BY

PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO

THE EQUIPMENT. THE UNIT MUST BE

INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES.

GAS RATINGS

Steamer Type

BTU/hr

Operating Pressure

(measured on top of gas valve)

Minimum

Incoming

Gas Feed

Maximum

Incoming

Gas Feed

3-Pan Natural Gas

54,000

4.30" WC

5" WC

14" WC

3-Pan LP Gas

54,000

10.5" WC

12" WC

14" WC

5-Pan Natural Gas

62,000

4.25" WC

5" WC

14" WC

5-Pan LP Gas

62,000

10.5" WC

12" WC

14" WC

10-Pan Natural Gas

106,000

4.30" WC

5" WC

14" WC

10-Pan LP Gas

106,000

10.5" WC

12" WC

14" WC

Steamer Type

NPT Pipe Size

Required

3-Pan Table Top

1/2

3-Pan on stand

1/2

(2) 3-Pan on stand

1/2

5-Pan table top

1/2

5-Pan on stand

1/2

(2) 5-Pan on stand

1/2

10-Pan on stand

3/4

(2) 10-Pan on stand

3/4

WARNING

THE AREA DIRECTLY AROUND THE

APPLIANCE MUST BE CLEARED OF ALL

COMBUSTIBLE MATERIAL. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN CAUSE

BODILY INJURY AND/OR PROPERTY DAMAGE.

IN CANADA, THE INSTALLATION MUST

CONFORM TO THE CANADIAN GAS CODE,

CAN 1-B149, INSTALLATION CODES FOR GAS

BURNING APPLIANCES AND EQUIPMENT

AND/OR LOCAL CODES.