Installation – Blodgett SB-E Series User Manual

Page 9

OM-E-SB 7

Installation

2. Water Connection

a.

Cold water is supplied via a 1/2” NPT pipe connection at the rear of the

unit. A check valve (back siphonage device) must be installed in accord

with local plumbing codes.

b. Water pressure should be between 30 and 60 PSI. If it is over 60 PSI, a

pressure regulator is required. A strainer screen at the connection is also

recommended, to trap any debris before it can enter the system.

c.

The boiler uses water at the maximum rate per hour shown below.

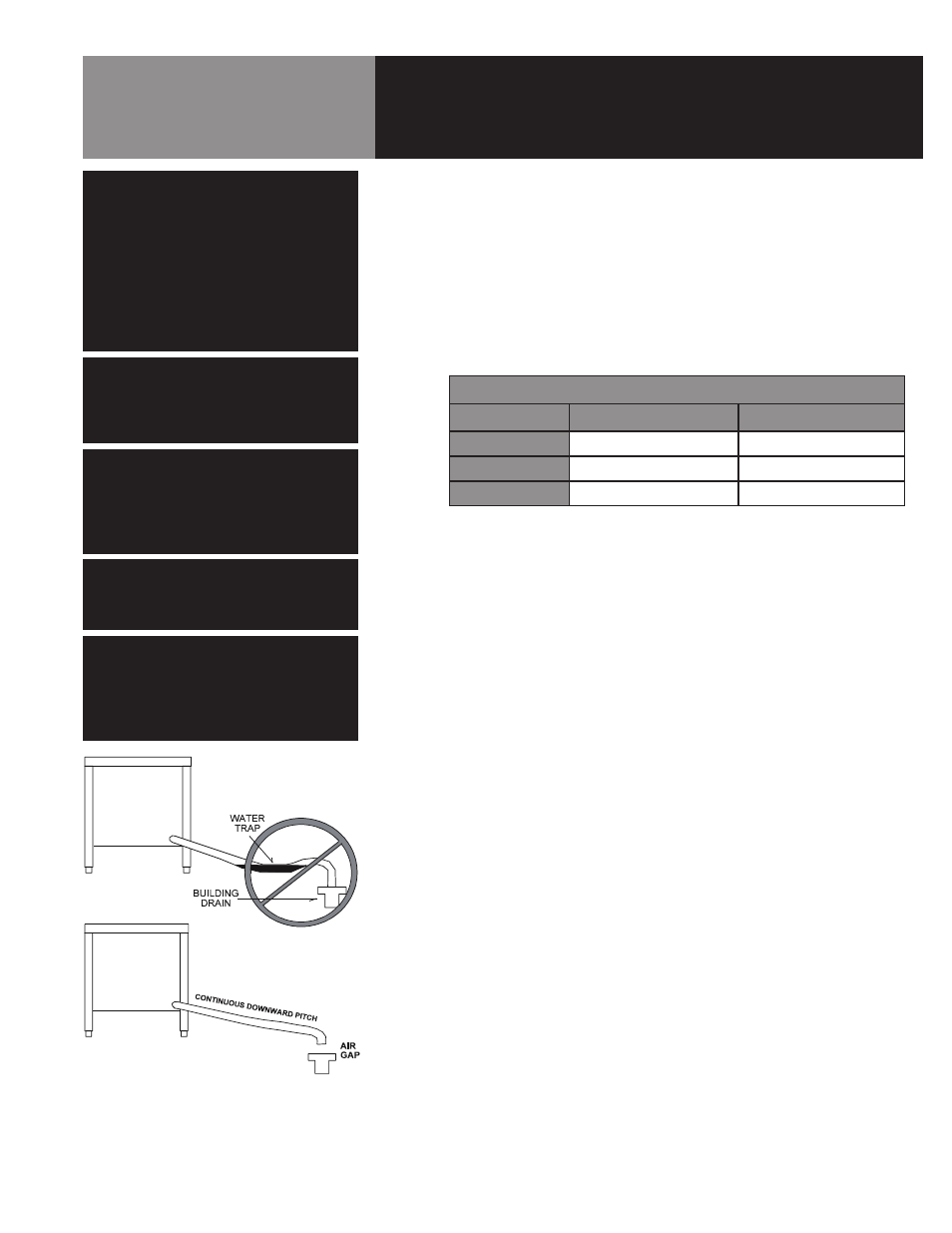

3. Drain Connection

a.

The drain connection is made at the rear of the unit with 1 - 1/4” NPT pipe.

DO NOT USE PLASTIC PIPE. DRAIN PIPING MUST WITHSTAND STEAM AND

BOILING WATER. Extend the drain piping to a nearby floor drain. Piping of

1 - 1/4” NPT (or 1 - 1/2” NPT) is acceptable for distances of six feet or less.

If the distance to the drain is further than six feet, use 2” NPT piping.

b. The drain line must be installed with a constant downward pitch. Do not

permit any water traps in the line. DO NOT CONNECT THE LINE DIRECTLY

TO ANY BUILDING DRAIN. A vertical air gap of at least two inches must be

maintained between the drain line and the building drain unless otherwise

specified by local plumbing codes.

4. Safety Valve

Ensure that the safety valve (see picture, Page 12) is vented properly. The

following Installation Instruction WARNING is quoted from the safety valve

manufacturer:

“During operation this valve may discharge large amounts of steam and/or hot

water. Therefore, to reduce the potential for bodily injury and property damage, a

discharge line MUST be installed that:

a.

is connected from the valve outlet to a safe point of discharge with no

intervening valve.

b. allows complete drainage of both the valve and the discharge line.

c. is independently supported and securely anchored so as to avoid applied

stress on the valve.

d. is as short and straight as possible.

e. terminates freely to atmosphere where any discharge will be clearly visible

and is at no risk of freezing.

f. terminates with a plain end which is not threaded.

g. is constructed of a material suitable for exposure to temperatures of 375°F

or greater

h. is, over its entire length, of a pipe size equal to or greater than the valve

outlet.”

WARNING

THE UNIT MUST BE INSTALLED BY

PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO

THE EQUIPMENT. THE UNIT MUST BE

INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

IMPORTANT

IMPROPER DRAIN CONNECTION

WILL VOID WARRANTY.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION.

THEY CAN SNAP BACK VIOLENTLY AND

CAUSE INJURY WHEN CUT.

CAUTION

MAKING ELECTRICAL OR MECHANICAL

CHANGES TO THE UNIT WITHOUT APPROVAL

FROM THE FOOD SERVICE ENGINEERING

DEPARTMENT WILL VOID WARRANTIES.

CAUTION

DO NOT LOCATE THE BOILER CABINET

DIRECTLY OVER A FLOOR DRAIN OR

FLOOR SINK. HUMIDITY OR WATER

WILL DAMAGE ELECTRICAL.

MAXIMUM WATER CONSUMPTION

Unit

Gallons/Hour

Liters/Hour

24 kW

8.2

31

36 kW

12.5

47.3

48 kW

16.9

64

Leave an air gap between the hose and the building

drain, and don’t allow water traps in the line.