Installation, Oven assembly – Blodgett 900 SERIES User Manual

Page 9

7

Installation

Oven Assembly

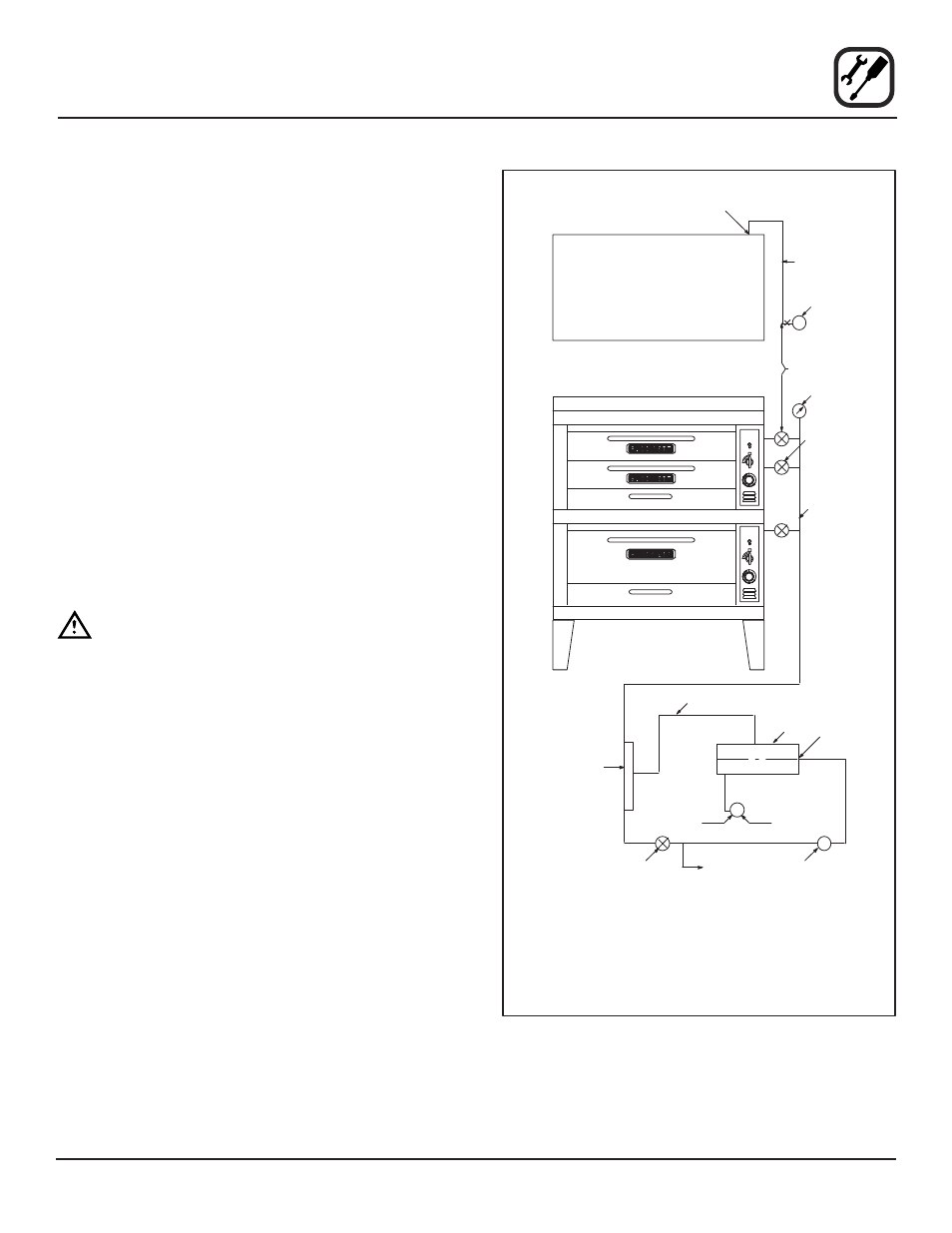

STEAM INJECTION

As an optional feature, all 900 Series ovens may be sup-

plied with steam jets for baking hard rolls, and vienna,

french or other hard crusted breads. This item is also

available as a kit which may be installed in the field. To

a baker, steam actually means an atmosphere of water

vapor. Therefore, it is very important that the steam be

low pressure (2-1/2 to 3 PSI), that condensate be taken

from the steam line before it enters the oven, and that the

steam be sufficiently saturated to give the vapor cloud

effect required.

At least one quarter boiler horsepower for all large 900

Series compartment (42” x 32”) or two small 900 Se-

ries compartments (33” x 22”) is recommended. Several

firms manufacture electric and gas fired steam genera-

tors ranging in size from 1/2 boiler horsepower upward.

If the steam generator is mounted adjacent to the oven,

line transmission losses will be insignificant. If the steam

source is located a considerable distance from the oven,

line transmission losses must be considered in determin-

ing the proper size of the steam. Please refer to the ac-

companying diagram for the recommended installation of

the steam injection system.

WARNING!!

Gas Flame in oven must be turned off when

steam is in use.

Figure 5

3/8” steam connection

on back of oven

3/8” pipe

1/2” riser

See Note 1

Pressure

gauge

See Note 2

1/2” riser

Steam

separator,

make from

1/2” pipe,

12” long.

3/4” minimum

Boiler

Water level

Pressure

reducing

valve

From steam

source

Hand operated valve

To drain

Trap

NOTES:

1. 3/8”

Control Valve. Use dial type handle to obtain uniform

bake-to-bake results

2. Ideal steam condition at this valve, 2-3#PSI, 224-230 F.