Installation, Gas connection – Blodgett DFG-100 XCEL User Manual

Page 12

10

Installation

Gas Connection

GAS PiPinG

A properly sized gas supply system is essential for maxi-

mum oven performance. Piping should be sized to pro-

vide a supply of gas sufficient to meet the maximum de-

mand of all appliances on the line without loss of pressure

at the equipment.

Example:

NOTE: BTU values in the following example are for

natural gas.

You purchase a DFG-100 XCEL convection oven to add

to your existing cook line.

1. Add the BTU rating of your current appliances.

Pitco Fryer

120,000 BTU

6 Burner Range

60,000 BTU

Deck Oven

50,000 BTU

Total

230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total

230,000 BTU

DFG-100 XCEL (high rate) 80,000 BTU

New Total

310,000 BTU

3. Measure the distance from the gas meter to the cook

line. This is the pipe length. Let’s say the pipe length

is 40’ (12.2 m) and the pipe size is 1” (2.54 cm).

4. Use the appropriate table to determine the total ca-

pacity of your current gas piping.

The total capacity for this example is 320,000 BTU. Since

the total required gas pressure, 310,000 BTU is less than

320,000 BTU, the current gas piping will not have to be

increased.

NOTE: The BTU capacities given in the tables are for

straight pipe lengths only. Any elbows or other

fittings will decrease pipe capacities. Contact

your local gas supplier if you have any ques-

tions.

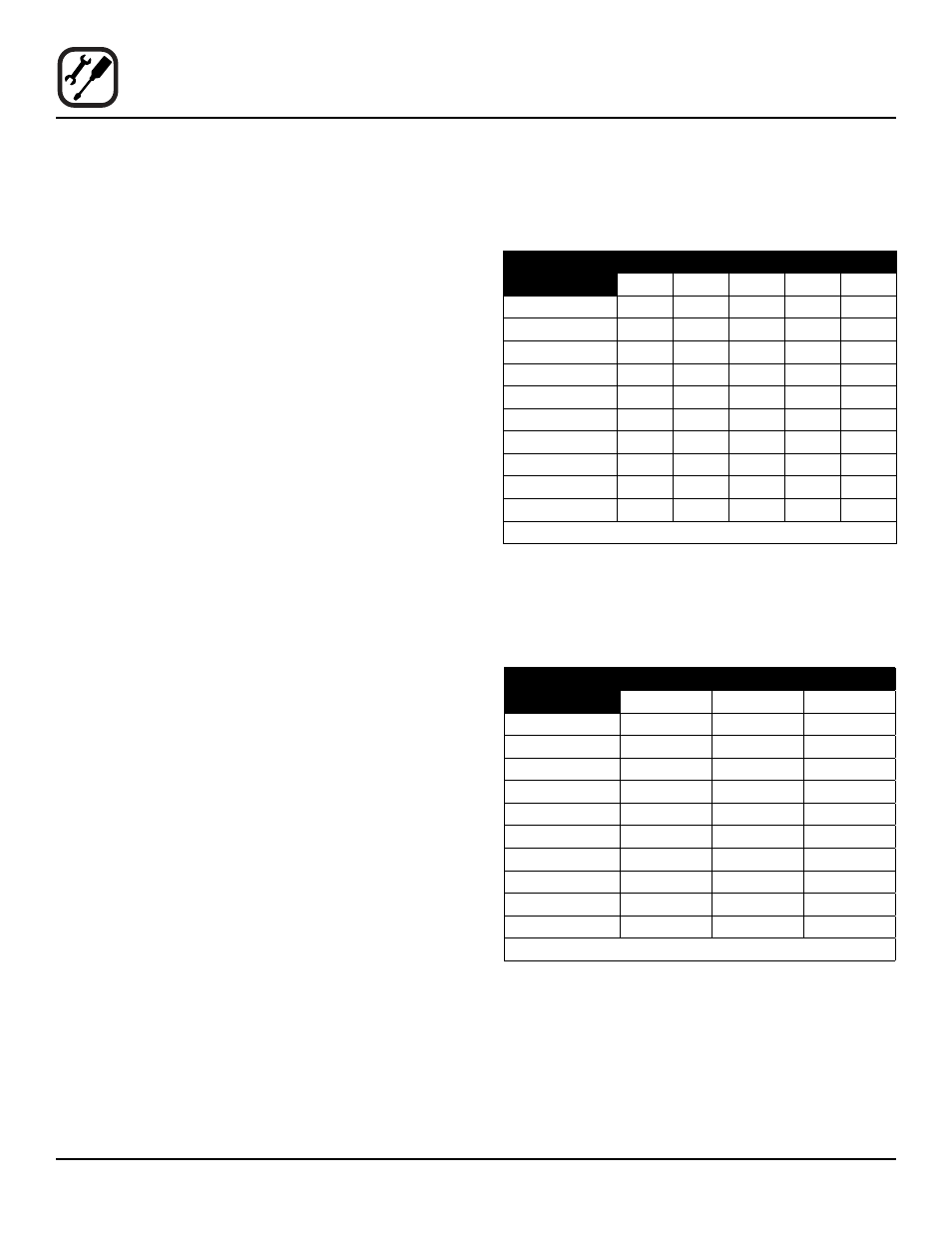

Maximum Capacity of iron Pipe in Cubic Feet of

natural Gas Per hour

(Pressure drop of 0.5 Inch W.C.)

PiPE

LEnGth (Ft)

noMinAL SizE, inChES

3/4”

1”

1-1/4” 1-1/2”

2”

10

360

680

1400

2100

3950

20

250

465

950

1460

2750

30

200

375

770

1180

2200

40

170

320

660

990

1900

50

151

285

580

900

1680

60

138

260

530

810

1520

70

125

240

490

750

1400

80

118

220

460

690

1300

90

110

205

430

650

1220

100

103

195

400

620

1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in thousands of

BtU/hr of Undiluted L.P. Gas at 11” W.C.

(Pressure drop of 0.5 Inch W.C.)

PiPE

LEnGth (Ft)

oUtSiDE DiAMEtER, inChES

3/4”

1”

1-1/2”

10

608

1146

3525

20

418

788

2423

30

336

632

1946

40

287

541

1665

50

255

480

1476

60

231

435

1337

70

215

404

1241

80

198

372

1144

90

187

351

1079

100

175

330

1014

From the National Fuel Gas Code Part 10 Table 10-15