Installation, Oven description and specifications – Blodgett Mark V-100 User Manual

Page 4

2

Installation

Oven Description and Specifications

eLectricaL ratinGS- Mark v-100 and Mark v-200

voLtaGe

hz

kW

PhaSe

Max Load (aMPS

Motor

L1

L2

L2

N

U.S. and canadian installations - all models

208

60

11.0

1

51

—

51

—

6 AWG

208

60

11.0

3

31

29

29

—

8 AWG

220-240

60

11.0

1

44

—

44

—

6 AWG

220-240

60

11.0

3

26

24

24

—

8 AWG

440

60

11.0

3

15

14

14

—

12 AWG

480

60

11.0

3

14

13

13

—

12 AWG

General export installations - Mark v-100

208

50

11.0

3

18

18

18

4

Size per local code

220-240

50

11.0

1

48

—

—

48

Size per local code

220/380

50

11.0

3

18

16

16

2

Size per local code

240/415

50

11.0

3

18

14

14

4

Size per local code

230/400

50

11.0

3

18

15

15

3

Size per local code

General export installations - Mark v-200

220/380

60

11.0

3

18

15

15

3

Size per local code

220/380

50

11.0

3

18

15

15

3

Size per local code

240/415

50

11.0

3

18

14

14

4

Size per local code

230/400

50

11.0

3

18

15

15

3

Size per local code

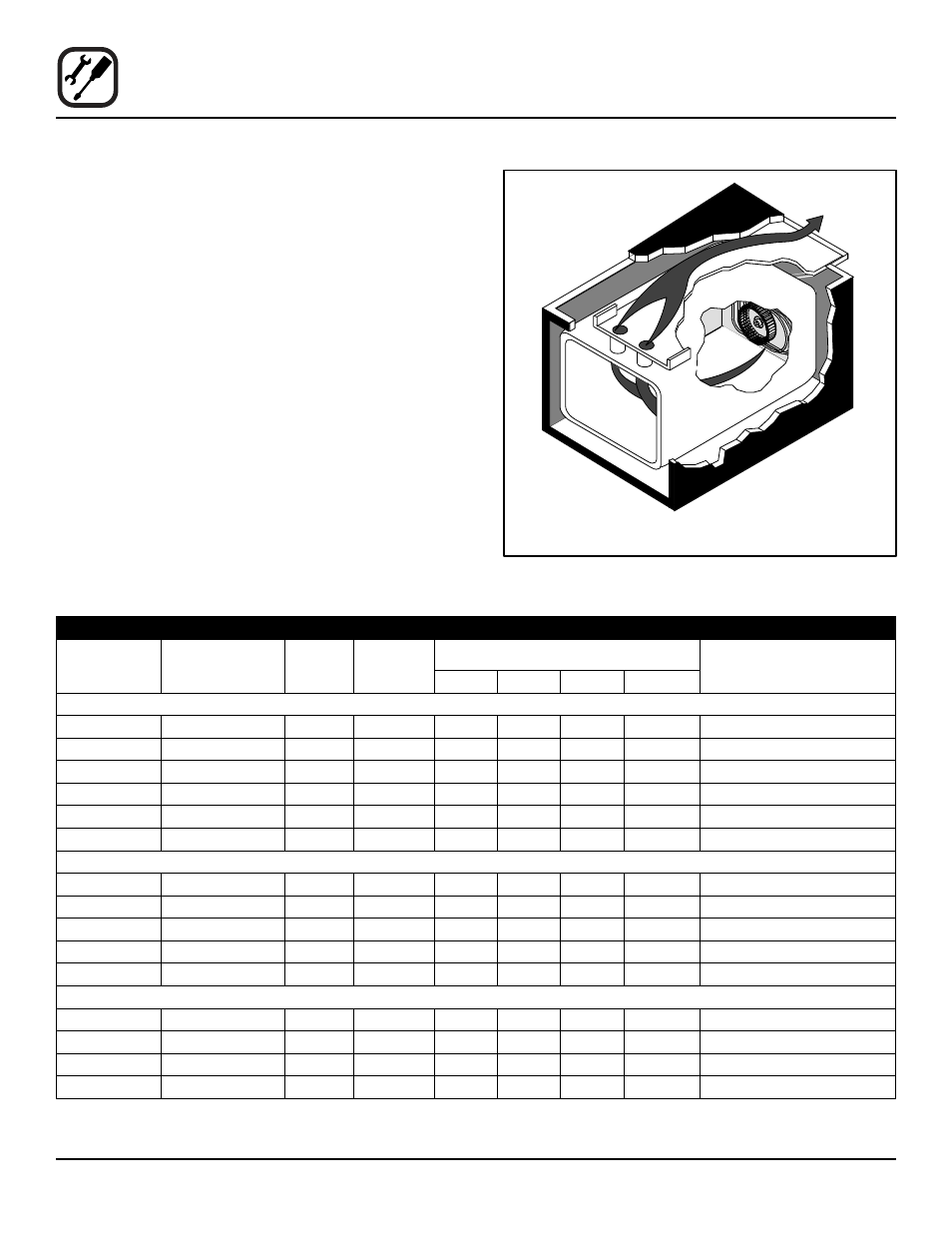

Cooking in a convection oven differs from cooking in a

conventional deck or range oven since heated air is con-

stantly recirculated over the product by a fan in an en-

closed chamber. The moving air continually strips away

the layer of cool air surrounding the product, quickly al-

lowing the heat to penetrate. The result is a high qual-

ity product, cooked at a lower temperature in a shorter

amount of time.

Blodgett convection ovens represent the latest advance-

ment in energy efficiency, reliability, and ease of opera-

tion. Heat normally lost, is recirculated within the cooking

chamber before being vented from the oven: resulting in

substantial reductions in energy consumption and en-

hanced oven performance.

Air Flow Pattern for Blodgett Electric Convection Ovens

Figure 1