5 fans, 6 thermal interface material, Fans – AMD 1207 User Manual

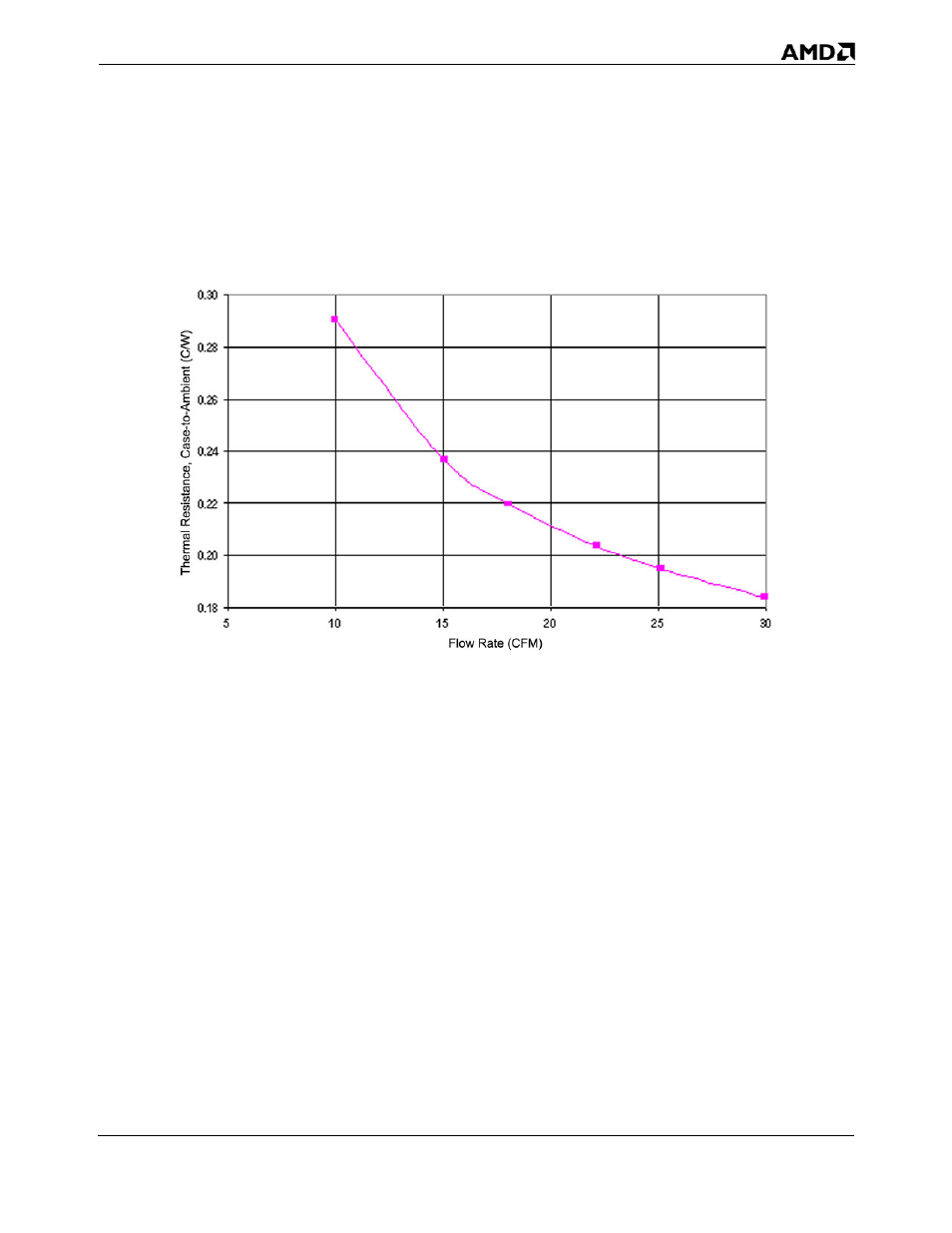

Page 35: Thermal interface material, Figure 11, Figure 11 shows the measured thermal performance

Chapter 5

Thermal Design of Custom 2U-4P Systems

35

Thermal Design Guide for Socket F (1207) Processors

32800

Rev. 3.02

August 2006

on flow simulations of an AMD reference 2U system, the flow-through of the heat sink is

approximately 18 CFM. Figure 11 shows that this flow rate corresponds to a case-to-ambient thermal

resistance of 0.22°C/W. This case-to-ambient thermal resistance exceeds requirements (see Table 7

on page 30).

Figure 11.

Thermal Performance Chart of Heat Sink When Used with a Dual-Core Processor

in 90 nm Process

5.3.5

Fans

AMD has conducted simulations of the heat sink described in Section 5.3.4 on page 33 with two 60

mm x 60 mm x 38 mm fans (Delta Part number FFB0812EHE-HS2) in series, that is, back to back.

The fans have a maximum flow rate of 80.2 CFM and a maximum pressure drop of 0.8 inches of

water. The heat sinks are ducted so the flow from the two fans enters the processor heat sinks with

some bypass. The bypass is designed to cool the core VRM.

5.3.6

Thermal Interface Material

The heat sink makes contact with the top surface of the processor package utilizing the thermal

interface material between the processor lid and the heat sink. AMD recommends using a high

performance grease such as Shin-Etsu 7783D or Dow Corning TC-5022. AMD does not recommend

using phase change materials between the heat sink and the processor. Phase-change materials

develop high adhesion forces between the heat sink and processor when the material is in the solid

phase. This strong adhesive force may cause the processor to stick to the heat sink, making heat sink

removal difficult and damaging the socket solder balls.