2 thermal solution design requirements, 3 sample heat sinks and attachment methods, Thermal solution design requirements – AMD 1207 User Manual

Page 22: Sample heat sinks and attachment methods, Table 4

22

Thermal Design of Custom 1U-2P Systems

Chapter 4

32800

Rev. 3.02

August 2006

Thermal Design Guide for Socket F (1207) Processors

Depending on the system features and layout, more space around the socket may be available for the

thermal solution than is shown in Figure 4 on page 21. This space permits heat sink designs with

better thermal performance.

Appendix B on page 45 shows a complete, detailed set of keep-out drawings for custom 1U-2P

systems based on socket F (1207) processors.

4.2

Thermal Solution Design Requirements

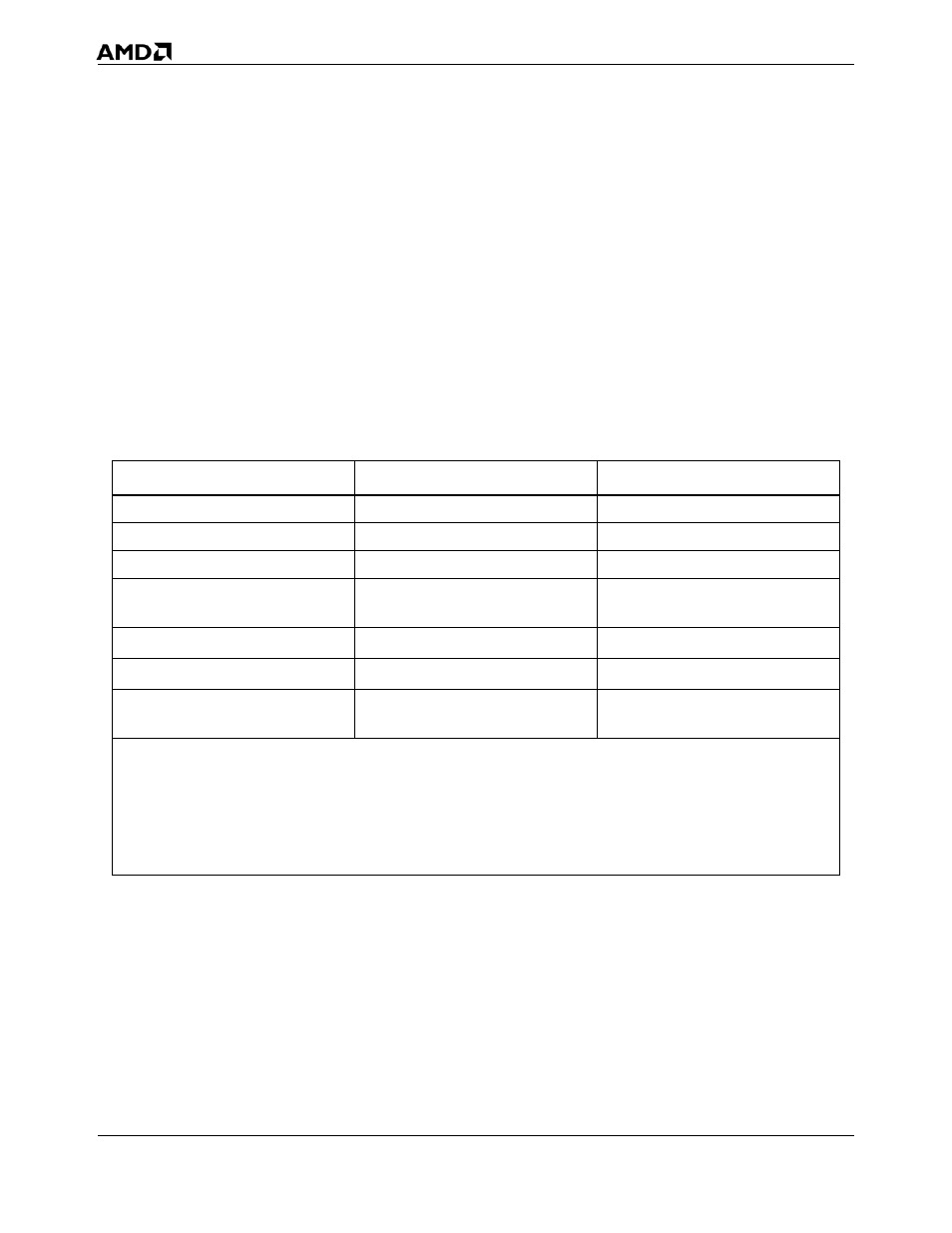

To maintain the case temperature of the processor below the maximum specification, certain heat sink

design parameters must be considered. Table 4 provides the design-target specifications that must be

met for socket F (1207) processors to operate reliably.

4.3

Sample Heat Sinks and Attachment Methods

The following sections provide one possible thermal design solution and the specifics on attaching

that solution to the motherboard.

Table 5 on page 23 lists the parts used in the thermal reference design solution for 1U-2P systems

based on socket F (1207) processors.

Table 4.

Thermal Solution Design Requirements for Custom 1U-2P Systems

Symbol

Description

Maximum

L

Length of heat sink

87 mm

W

Width of heat sink

74 mm

H

Height of heat sink

28 mm

θ

ca

Case-to-ambient thermal

resistance

0.26°C/W

1, 2, 3

M

HS

Mass of heat sink

450 g to 700 g

F

clip

Clip force

75 lbs ±15 lbs

T

A

Local air temperature entering

processor heat sink

38°C

Notes:

1. This is the thermal resistance required for dual core, 90-nm socket F (1207) processors. The thermal resistance

requirement may vary depending on the product OPN. The user should consult the processor data sheet for the

thermal requirements specific to the part.

2. Heat sinks weighing up to 450 g can be attached to the motherboard. Heat sinks weighing over 450 g should be tied

directly to the chassis for more reliable shock and vibration performance.

3. This chapter describes a heat sink weighing less than or equal to 450 g.