Parallel connections – A.O. Smith 120 through 250 Series User Manual

Page 31

Instruction manual BFC

31

is

3.9.4

Parallel connections

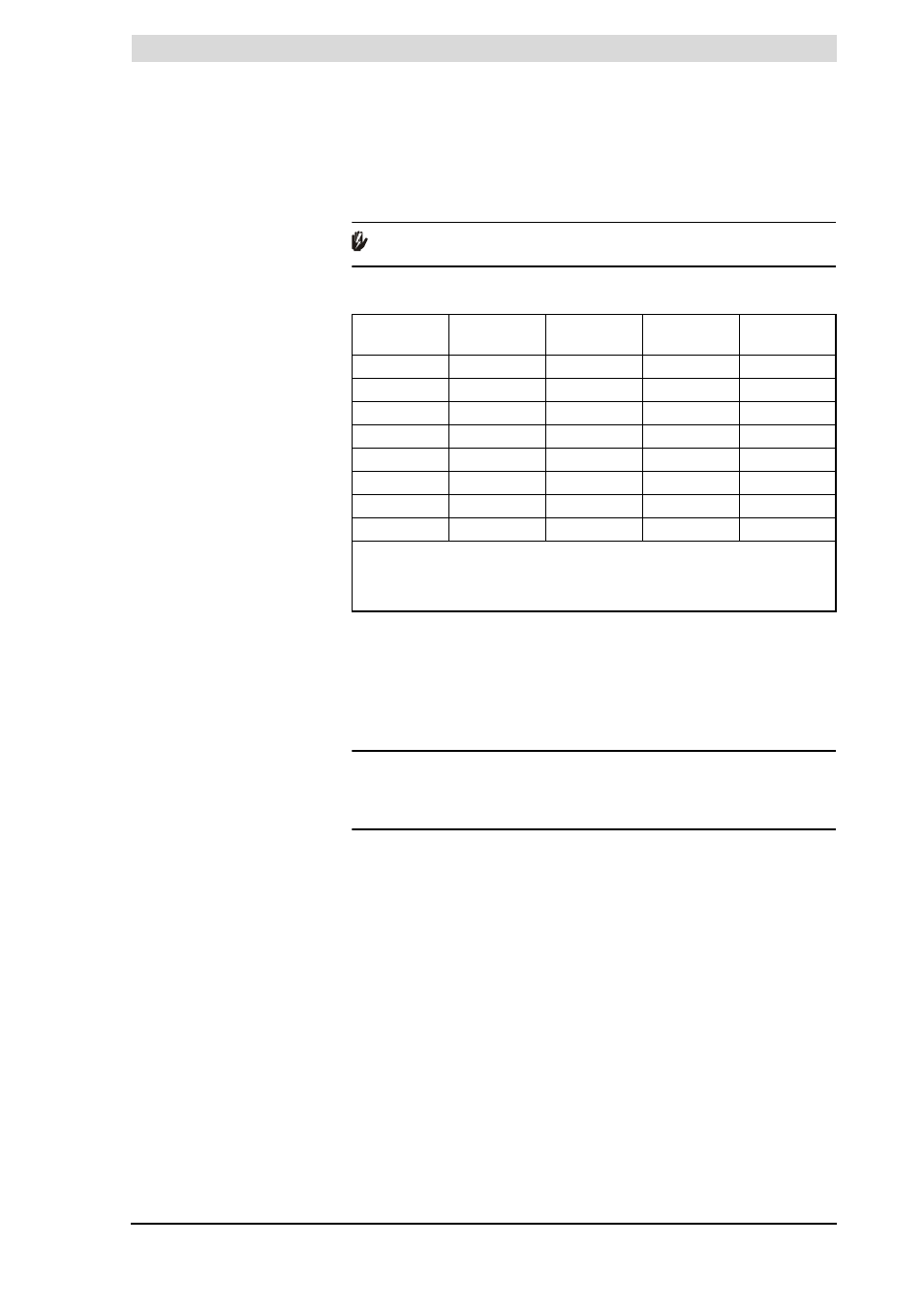

The table states the maximum pipe lengths for parallel systems. The maximum

pipe length depends on the chosen diameter.

Warning

Install flue component pipe runs with a run-off of 5 mm per metre.

Flue gas outlet requirements for parallel systems

You must use the longest pipe when calculating the pipe length. For example, if

the chimney pipe is 35 metres and the air supply pipe is 32 metres, use 35

metres as the length for the calculation. Next, add the L

equivalent

for every 90°

and 45° bend to this 35 metres, in both the air supply and flue gas outlet. The

following practical example illustrates how to use the table.

Practical example of parallel flue gas outlet

Example

The diagram shows a BFC 30. This has to be fitted with a 25m parallel pipe

100mm in diameter, plus eight 90-degree bends. The configuration must be

checked for compliance with the requirements stated in the table.

Appliance

Diameter

1

Maximum

total length

L

equivalent

90º bend

L

equivalent

45º bend

BFC 28

80mm

25m

3.9m

1.1m

BFC 30

100mm

80m

4.6m

1.2m

BFC 50

100mm

45m

4.6m

1.2m

BFC 60

100mm

25m

4.6m

1.2m

BFC 28

100mm

100m

4.6m

1.2m

BFC 30

130mm

100m

2.4m

1.4m

BFC 50

130mm

100m

2.4m

1.4m

BFC 60

130mm

100m

2.4m

1.4m

1) Parallel systems with diameter of 130mm or 150mm. If the maximum total

length for a diameter of 130mm is insufficient, 150mm diameter must be used.

Any diameter enlargement must be carried out on both air supply and flue gas

outlet.