Maintenance, 1. troubleshooting chart, Table 9-1 – Campbell Scientific OBS-3+ and OBS300 Suspended Solids and Turbidity Monitors User Manual

Page 32

OBS-3+ and OBS300 Suspended Solids and Turbidity Monitors

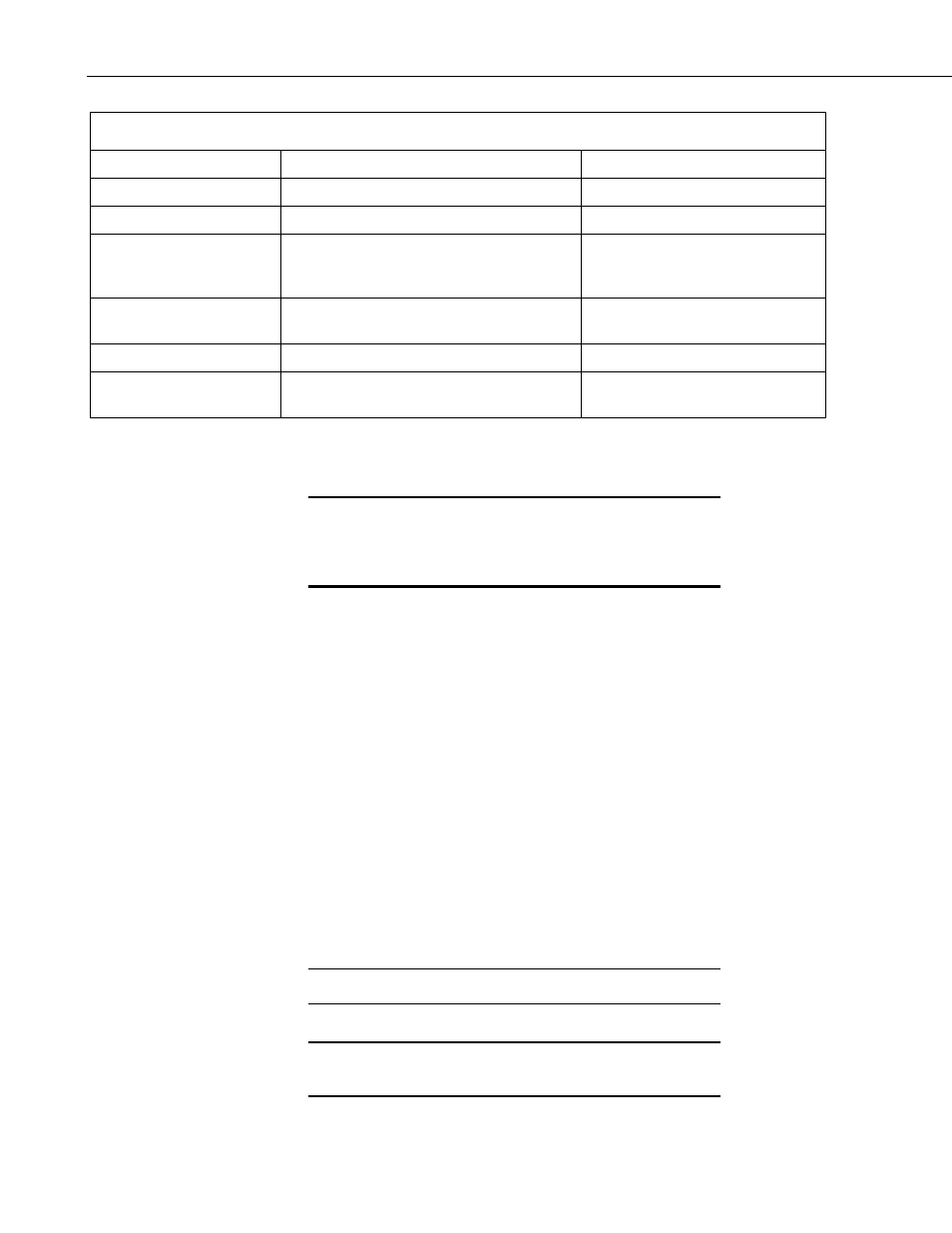

TABLE 9-1. Troubleshooting Chart

Fault

Cause of Fault

Remedy

Fails finger wave test

No power, dead battery

Replace battery and reconnect wires

MCIL-5 plug not fully seated

Disconnect and reinsert plug.

Sensor broken

Visually inspect for cracks. Return

the sensor to manufacturer if cracks

are found.

Electronic failure. Units draws less than 11

mA or more than 40 mA.

Return the sensor to manufacturer.

Fails shake test

Sensor leaked

Return the sensor to manufacturer.

Fails calibration check

Aging of light source causes it to get dimmer

with time.

Recalibrate (see Section 8,

Calibration)

10. Maintenance

There are no user-serviceable parts inside the sensor

housing. Do not remove the sensor or connector from

the pressure housing. This will void the warranty and

could cause a leak.

The most important maintenance item is keeping the window clean. A

Scotch-Brite scouring pad works well for most types of window fouling.

First wet the pad and then place it on a counter with a plastic-laminate top so

that the side of the pad is aligned with the edge of the counter. Work the

window of the OBS sensor back and forth on the pad until it is clean while

removing as little epoxy as possible. If encrusting organisms such as barnacles

or tube worms have attached to the sensor, it will have to be gently scraped

with a flexible knife blade prior to using the pad. Some applications will result

in pitting of the sensor face. Pits can be removed with abrasive cloth. Polish

the sensor window as follows:

1. Tape a strip of 400 grit wet-or-dry abrasive cloth to the edge of a

counter (see above).

2. Add a few drops of water to the abrasive and work the sensor window

in smooth one-way strokes on the cloth using the counter edge as a

guide.

3. Continue until the sensor is shiny and pit free.

It is important to remove as little epoxy as possible.

Do not use solvents such as MEK, toluene, acetone, or

trichloroethylene on OBS sensors.

WARNING

NOTE

WARNING

22