3 operating sequence, 1 sampling sequence, Operating sequence – Campbell Scientific CVS4200 / BVS4300 Stationary Samplers User Manual

Page 36: Sampling sequence

CVS4200 / BVS4300 Stationary Samplers

7.3 Operating Sequence

7.3.1 Sampling Sequence

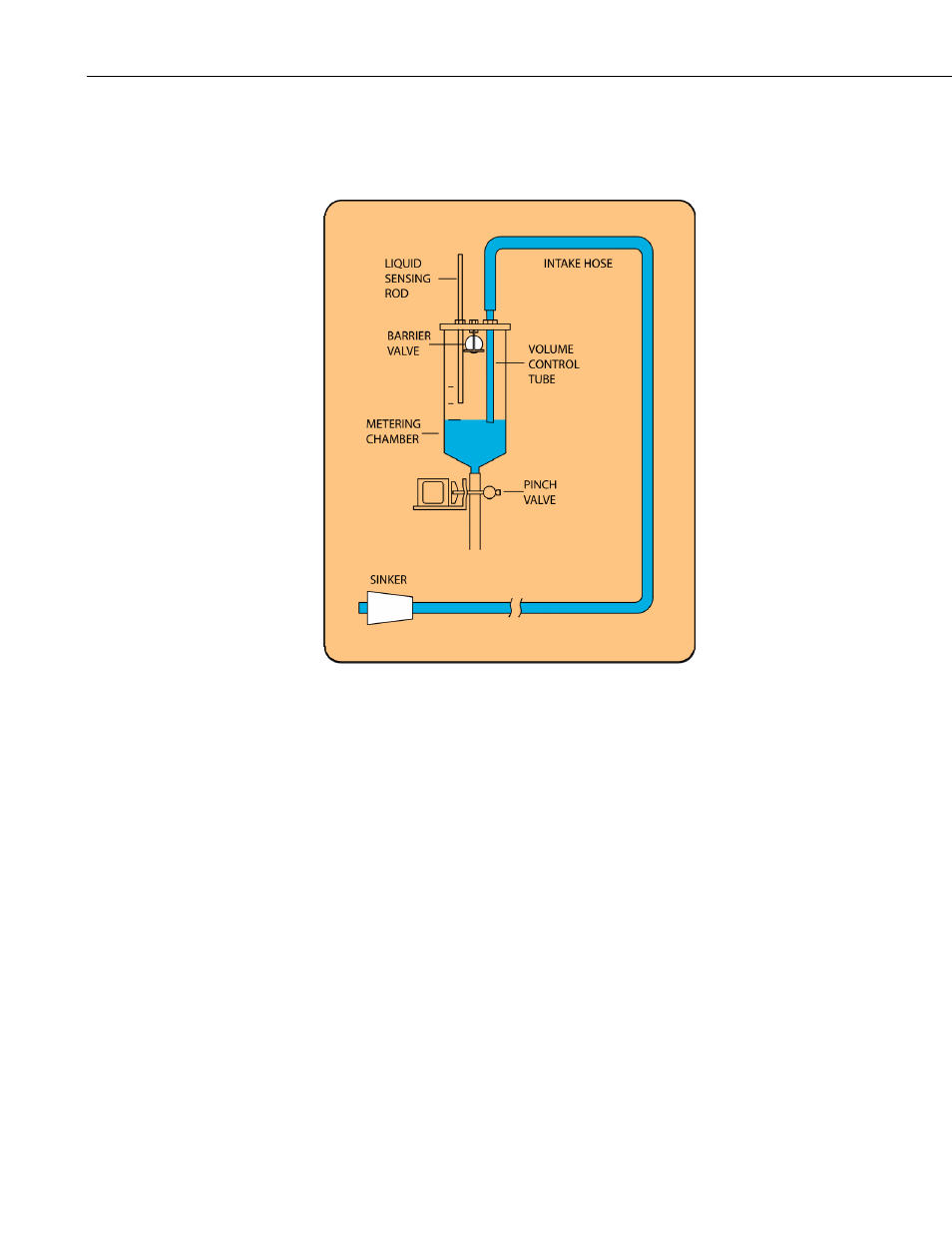

SAMPLING PROCESS:

1. High pressure air purge of intake hose.

2. Liquid is drawn into the metering chamber, up to the liquid sensing rod.

3. All excess liquid is purged from the system down to the level set by the

volume control tube.

4. The sample is then released into either one composite container or one of

several discrete containers.

The sampling sequence begins with a high pressure air purge of the intake

assembly to remove residual liquid and obstructions. Upon completion of the

pre-purge cycle, the system converts to a vacuum state, drawing the sample

through the intake hose into the metering chamber. The system then

pressurizes, ejecting excess fluid back through the intake line until the

predetermined sample volume is achieved. The sample is then deposited under

pressure into the sample container while the post purge again clears the intake

line of any residual liquid.

Should the sampler, for any reason, not be able to draw a sufficient volume of

fluid to obtain a sample, the unit automatically initiates a second attempt.

Should a sample still not be delivered, the sequence will be abandoned and the

unit will await the next initiation. Upon two consecutive failures, the sampler

will suspend the sampling program until manually RESTARTed.

28