3 quarter bridge strain with dummy gage – Campbell Scientific 4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules User Manual

Page 24

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Shield

18

H

L

G

Datalogger

Vx

H

L

or AG

H

or G

Jumper Wire

R

1

R

2

R

D

Gauge

4

7

3

4

2

93

.

3

25

.

3

05

.

0

15

.

1

95

.

2

T

E

T

E

T

T

TO

−

−

−

+

−

+

−

=

με

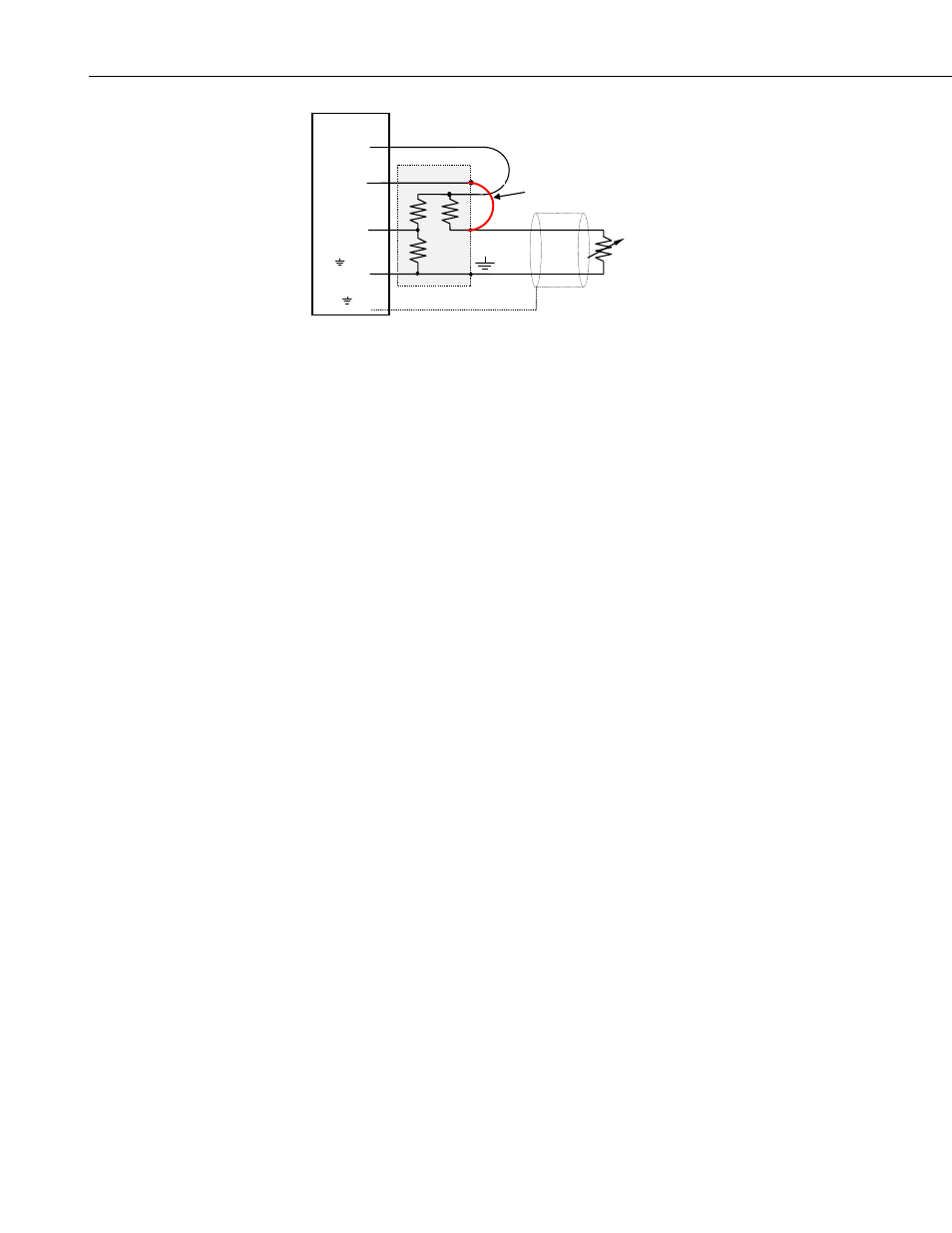

FIGURE 4.2-2. Wiring for 2-wire gauges

4.2.2 Two Wire ¼ Bridge use with Multiplexers and Equations

The equations to resolve the strain, programming of the logger, and methods of

using with multiplexers are the same as those covered in Section 4.1 for the 3-

Wire Strain gauge. The only variance is the wiring of the gage to the TIM.

4.3 Quarter Bridge Strain with Dummy Gage

An undesirable property of strain gauges is that of resistance change with

changes in temperature. This is true even for the self-temperature

compensating strain gages on the market today. Supplied with each package of

strain gages are graphs and equations for the variance in the output of the strain

gage due to thermal changes (referred to as thermal output or apparent strain)

and for the variation of the gage factor with temperature. These graphs are

based on the assumption that the gages are mounted on a material with the

given thermal coefficient of expansion (TCE). The TCE value is included in

the gage type nomenclature. Following are some typical equations supplied.

Equation 4.3.1 is used to calculate the thermal output variance (

µε

TO

) with the

result in μStrain. Equation 4.3.2 is used to determine the change in the gauge

factor (GF) due to temperature changes. Both are based on temperature in

degrees Celsius (T).

4.3.1

(

)

raw

raw

adj

GF

T

E

GF

GF

24

40

.

1

4

−

×

+

=

−

4.3.2

As an example, let us assume we use a gauge with a GF of 2.00 in a test that

started at 24°C and 0

μStrain, and ended at 50°C and a recorded strain value of

1000 μStrain. The thermal output strain,

µε

TO

, at 50°C would be -29.3

μStrain. The error in the gage factor would be 0.364% with a resultant GF

adj

of

2.007. The corrected strain would be 967 μStrain:

(

)

007

.

2

/

000

.

2

3

.

29

1000

με

=

−

με

με

×

cor

4.3.3

The uncorrected value had an error of approximately 3.3%. And if the ending

strain would have been 100 μStrain instead of 1000 μStrain, the error would

have been around 30%.