N~ rot, P. 400, D 1000 – Ashcroft GC52 - Rangeable wet/wet Differential Pressure Transmitter User Manual

Page 31: L 0.0, A 0.0, A100.0, U se, S bt, C 0.0

31

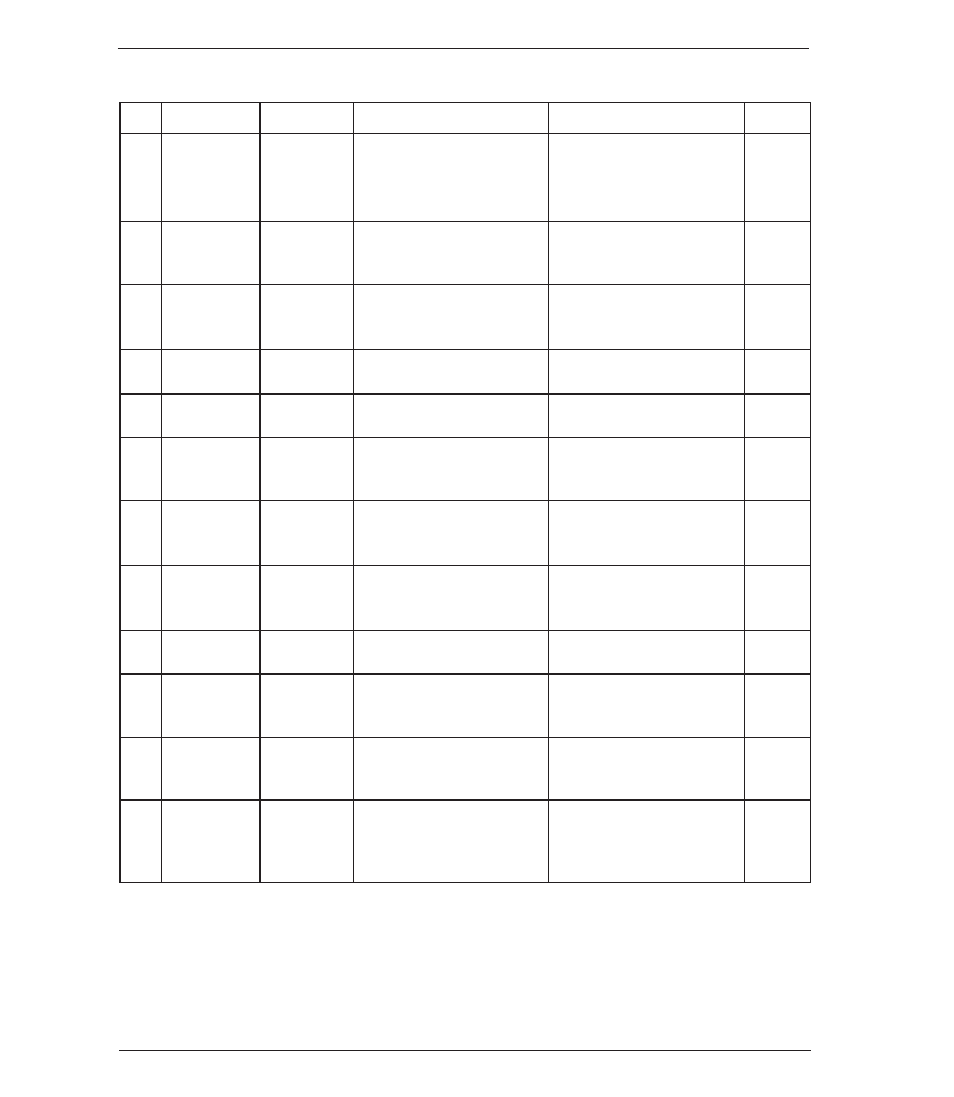

14.3 Flow Measurement/Square Root Extraction Mode

No.

Setting Item

LCD Display

Setting Description

Setting Range

Default

ባ

Display mode

n

~

roT

Selection for flow measure-

ment/ square root extraction

mode

non: Differential pressure

display mode Lin: Linear

display mode Rot: Square

root display mode

non

ተ

Maximum

differential

selection

1

p. 400

Maximum differential pres-

sure relating to the flow rate

25 to 100% F.S. of sensor

range

100.0%

of sensor

range

ቱ

Flow rate deci-

mal pt. position

D 0

Displays of value after deci-

mal point, # of digits

0,1,2,3 digit

0

ቲ

Max. momen-

tary flow

D 1000

Max. momentary of flow

using arbitrary units

0 to 1999

1000

ታ

Low cut

l 0.0

Forces display and output to

zero

0.0 to 30.0% F.S. of max.

display span

0.0

ቴ

Output zero

point

2

A 0.0

Momentary flow rate of ana-

log output zero point (4mA):

100.0% F.S.

–10 to 100% F.S. of max.

display span

0.0

ት

Output span

point

2

A100.0

Momentary flow rate of ana-

log output zero point

(20mA): 100.0% F.S.

–10 to 100% F.S. of max.

display span

100.0

ቶ

Time factor

U SE[

Measurement of max. mo-

mentary flow rate over time

selected

Seconds, minutes or hours

Sec

k

21

Flow rate vol-

ume factor

U 1

Flow rate x time selected

1,10,100,1000

1

k

22

Display

switch set-

ting

s bT

Selection of display switching

method of momentary flow

rate and integrated volume

ti = automatic

bt = manual

bt

k

23

Switch time

interval

T 5

Selection for ti: automatic

Displays switching time in-

terval in seconds

1 to 10 seconds (10 stage)

5

k

24

Loop check

3

c 0.0

Output check using arbitrary

value – displays pressure

correlating to the 4 to 20mA

signal

Display: momentary flow

rate display span

Analog output: 4 to 20mA

0.0 to 100.0%

0

(4.0mA)

(1) In the setting of a differential pressure the decimal point position is fixed for each differential pressure range. (Refer

to paragraph 12, Power-on Message). The max. differential pressure can be set from the value which is 25%F.S of

the differential pressure range above the minimum differential pressure.The values under 25%F.S. cannot be in-

creased or decreased by T, S key.

(2)

For setting zero point and span point of the analog output, input the percent value over the maximum display span

(between OFFSET and FULL SCALE). Its decimal point position can be set up to one digit after the decimal point (xx.x).

(3)

Regardless of generated differential pressure or low-cut, the loop check can be changed arbitrarily linking the mo-

mentary flow rate display with the analog output using the T, S keys. (Refer to 14.5.) This example of LCD display

shows the display set to span point.