Section 5 - troubleshooting, Troubleshooting -1 – Summers Superchisel - 5-Section User Manual

Page 59

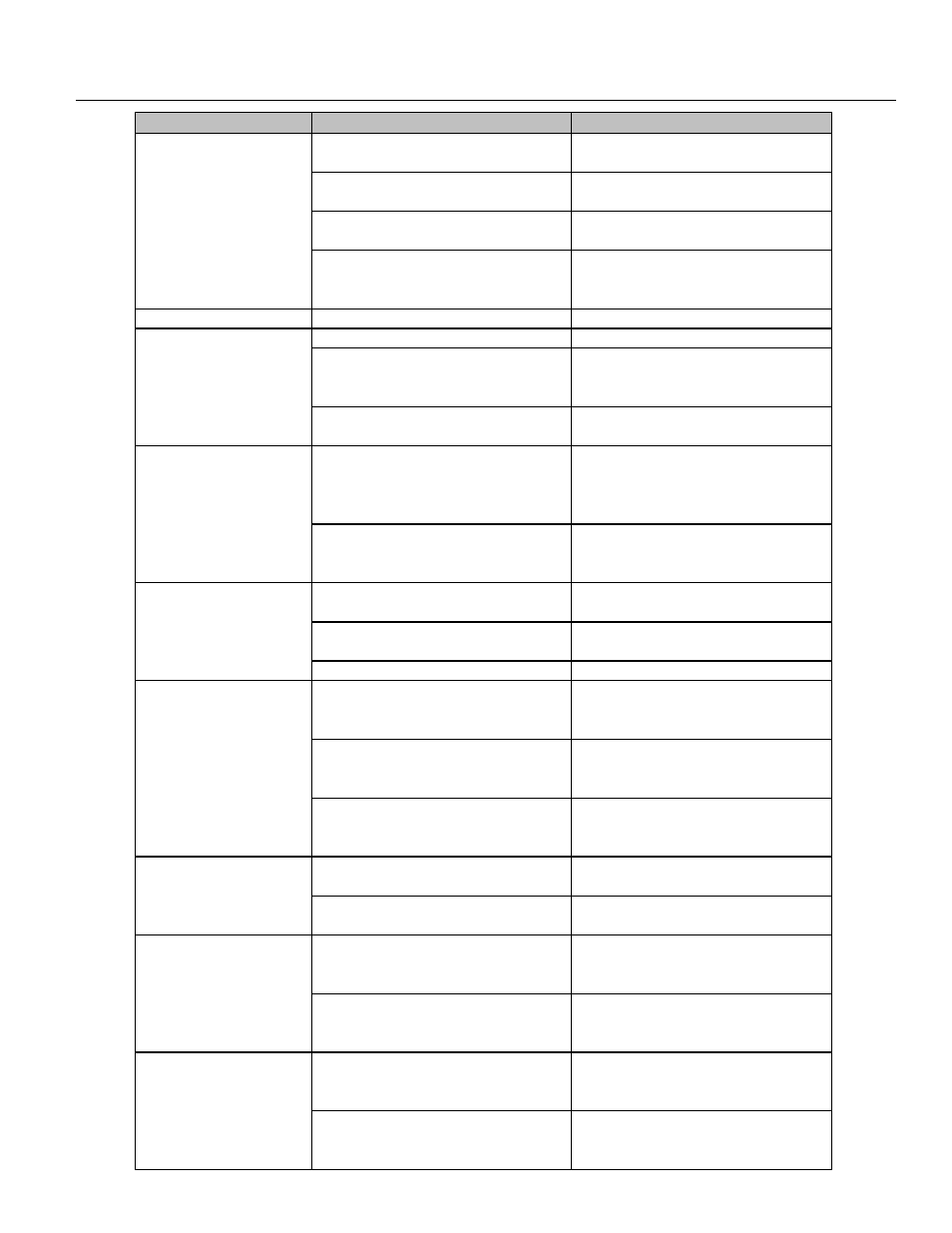

PROBLEM

CAUSE

CORRECTION

A. Depth control cylinders out of

phase.

Rephase cylinders. See Page 3-6.

B. Eyebolts not adjusted properly. Adjust with wrenches provided.

See Pages 3-8 and 3-9.

C. Gauge wheels not adjusted

properly.

Adjust gauge wheels so they ride

freely on top of the ground.

D. Hard soils conditions.

Use different tillage tool or perform

multiple passes, starting at less

depth.

2. Not pulling straight. A. Chisel plow not tilling level.

See "Not tilling level" above.

A. Excessive travel speed.

Reduce speed.

B. Hard soil conditions.

Use different tillage tool or perform

multiple passes, starting at less

depth.

C. Deep furrows.

Travel across field furrows at an

angle.

A. Working in extremely heavy

trash.

If equipped with mounted harrows,

reduce aggressiveness of harrows

or lock harrows in the up position.

B. Tillage tool (spike, sweep, etc.)

causing plugging.

Change type of tool. Make sure

twisted spikes are not throwing soil

towards wheels.

A. Machine not running level front

to back.

Adjust eyebolts on front center

wheel assembly.

B. Gauge wheels adjusted

improperly.

Adjust gauge wheels so they ride

freely on top of the ground.

C. Hard soil conditions.

Use different tillage tool.

A. Depth control cylinders out of

phase.

Rephase cylinders by fully

extending and holding tractor

remote lever for 30 seconds.

B. Hydraulic hoses not connected

properly or faulty coupler.

Reconnect hydraulic hoses or

replace hydraulic coupler.

C. Tractor hydraulics not set

properly.

Adjust tractor hydraulic flow rate to

maximum on Depth Control Circuit.

A. One way restrictor(s) not

installed properly.

Check restrictor(s) (PN 8J7116).

B. Tractor hydraulics not set

properly.

Reduce flow rate to Wing Lift

Cylinder Circuit.

A. Part 2 wing lift cylinder moving

before part 1 wing lift cylinders fully

extend.

Increase pressure in sequencing

valve that feeds base end of part 2

cylinders.

B. Part 2 wing lift cylinders not

extending.

Decrease pressure in sequencing

valve that feeds base end of part 2

cylinders.

A. Part 1 wing lift cylinders moving

before part 2 wing lift cylinders fully

retract.

Increase pressure in sequencing

valve that feeds rod end of part 1

cylinders.

B. Part 1 wing lift cylinders not

retracting.

Decrease pressure in sequencing

valve that feeds rod end of part 1

cylinders.

8. Wings do not unfold

properly.

9. Wings do not fold

properly.

6. Depth control

cylinders not working

properly.

7. Wing lift cylinders

move too fast.

1. Not tilling level.

3. Inconsistent tillage

depth.

4. Plugging.

5. Poor penetration.

5-1

SECTION 5 – TROUBLESHOOTING