Section 3 - operation & maintenance, Transport to field position, Field to transport position – Summers Hydraulic Fold Coil User Manual

Page 95: Section 3: operation and maintenance, Operating instructions -1 – 3-2

SECTION 3 - OPERATION and MAINTENANCE

3-1

OPERATING INSTRUCTIONS – HYDRAULIC FOLD IMPLEMENT

IMPORTANT: Do not exceed 20 MPH while transporting Implement. Do not attempt to raise or

lower Implement unless it is securely attached to an appropriate towing vehicle.

TRANSPORT TO FIELD POSITION

1. Hitch machine to tractor or implement using a locking hitch pin and safety chain. Connect hydrau-

lic hoses and wiring connector. Retract hitch jack and rotate into storage position.

2. Select a level area to lower machine into field position.

3. Remove transport locks. If locks do not remove freely, insure that cylinders are completely filled

with hydraulic fluid and are supporting the load to be lowered. Store locks in storage holes pro-

vided.

4. Activate hydraulic system to lower machine into field position (main lift cylinders fully retracted

and wing lift cylinders fully extended).

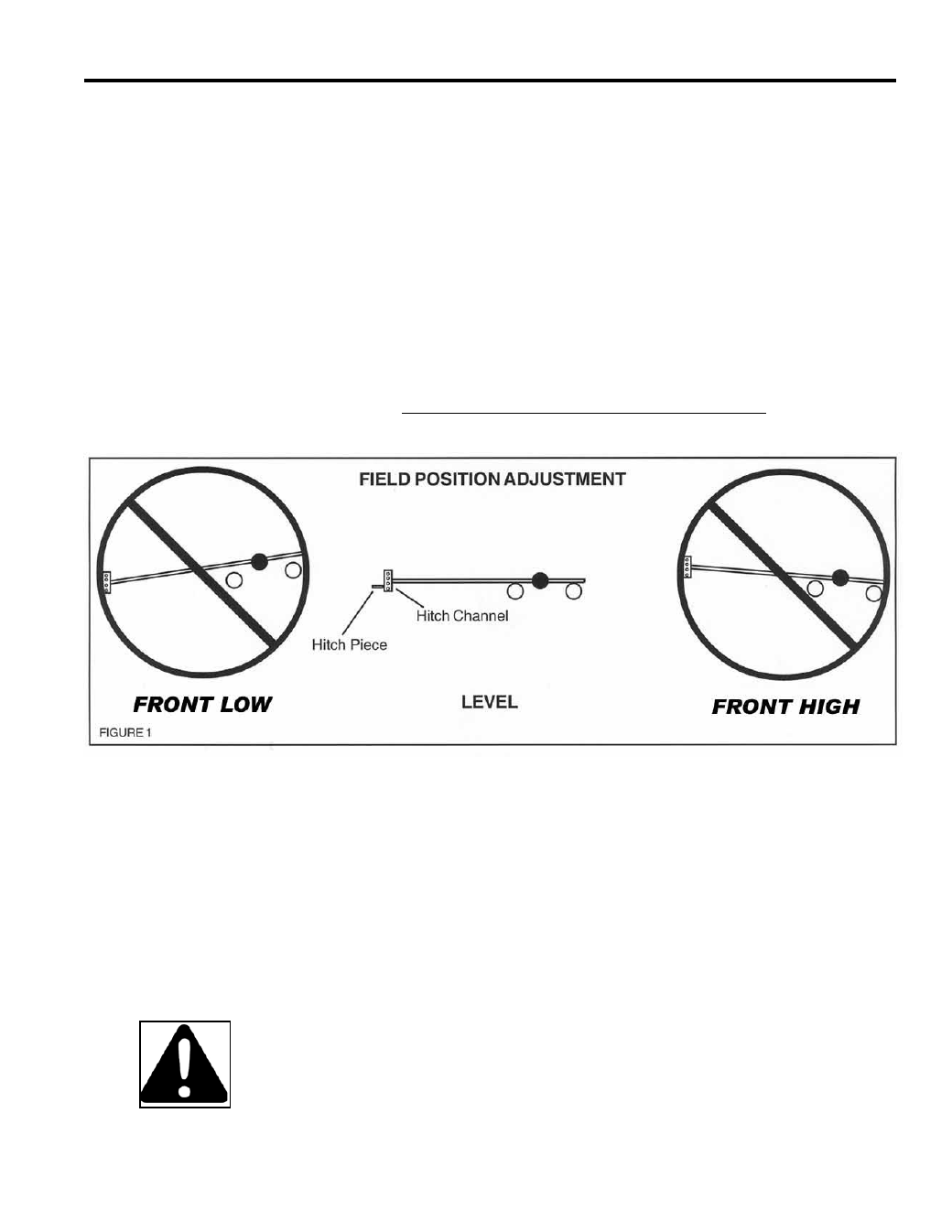

5. To insure even down pressure, the machine hitch must be level in field position. Adjust vertical

height of hitch piece if required.

6. Amount of machine weight supported by center 11L tires can be changed by adjusting Eye Bolts

above main lift hydraulic cylinders. NOTE: Lowering Eye Bolts will increase transport height.

NOTE: The Summers Hydraulic Fold Coil Packer is designed to provide an ideal seedbed as a last

pass operation either before or after seeding.

FIELD TO TRANSPORT POSITION

1. Stop in a level area.

2. Activate hydraulic system to raise machine into transport position (main lift cylinders fully ex-

tended and wing lift cylinders fully retracted).

3. Install transport locks.

Always be sure transport locks are engaged when making adjustments on

the machine int he raised or transport position.

4. Check wheel bolts after first 20 miles of road transport and every 60 miles thereafter.