Section 2 - assembly, 14' to 44' coil packer assembly, Section 2: assembly – Summers Hydraulic Fold Coil User Manual

Page 11: 14’ to 44’ set-up instructions -1 – 2-25

SECTION 2 - ASSEMBLY

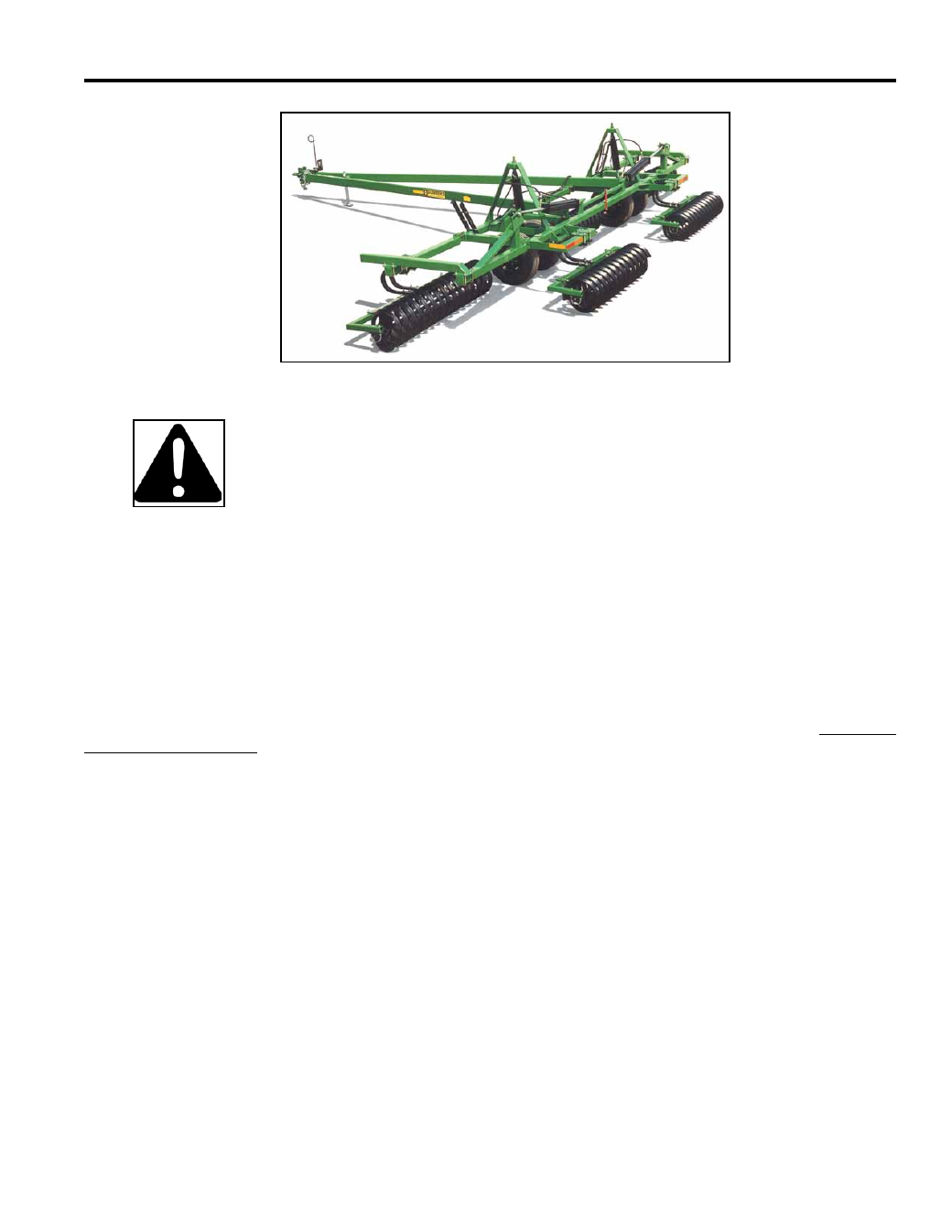

Refer to illustrations on following pages and follow these steps when assembling an 14’ to 44’ Summers Hydraulic Fold

Coil Packer or Hydraulic Fold Rolling Chopper. The machine should be placed in a firm, level area that allows ample

room for assembly in field position.

CAUTION: For safety purposes, block equipment while working on it.

CENTER ASSEMBLY

Place center section on stable supports approximately 2-1/2 ft. off floor. Install cylinder attach Eye Bolts. Set Eye Bolts in

middle of adjustment. Install hydraulic cylinders. Secure Main Lift Cylinders with 1” diameter pins and cotter pins. Secure

base end of Wing Lift Cylinders (8C0432) with 1” diameter pins and roll pins. Install center wheel lift arm assemblies

with 1-1/4” X 14” pins. Apply good quality Anti-Seize lubricant on pins prior to assembly. Secure with 1/2” X 1-3/4” cap

screws, lock nuts and flat washers (over slotted hole). Pre-Assemble Walking Axle assemblies (standard center only).

Attach Walking Axle assemblies to lift arm assemblies with 3/4” bolts, lockwashers and nuts.

WING ASSEMBLY

Install left and right wings. Secure with 1-1/4” diameter pins and roll pins. Connect front and rear wing sections with

cross braces. Refer to layout drawings to determine brace locations. Secure cross braces with 3/4” u-bolts. Attach

wing axle assemblies to outside wing cross brace using 3/4” u-bolts. Wing axle and hub assemblies are optional on

single coil/chopper wings.

HYDRAULIC SYSTEM

Install cylinder hydraulic fittings and hydraulic hoses between cylinders.

HITCH TUBES

Position hitch tube(s) on top of center section. Attach hitch tube(s) to center section with ¾” u-bolts, lockwashers and

nuts. Connect hitch tubes with hitch extension (8C5060, 8C5070 or 8C5100), hitch channel (8C5050) and hitch piece

(8D0720) at front of machine using hardware provided.

HYDRAULIC HOSES TO TRACTOR AND TIRES

Install hydraulic hoses and fittings to front of machine. Secure hoses with clamps provided. Do not over tighten, hy-

draulic hoses expand and shorten when pressurized. Install wheels and tires. Tighten wheel bolts to 170 ft-lb torque.

CHARGE HYDRAULIC SYSTEM

Block Wing Lift Hydraulic Cylinders (8C0432) so rods can fully extend without contacting wing (Photo 44a.). Connect

hydraulic tips to tractor hydraulic couplers. Extend and retract cylinders until air is purged from hydraulic system. At-

tach rod end of wing lift cylinders to wing lift slots with 1” X 7” bolt, flat washer, bushings and lock nut (Photo 44b.). Do

not overtighten lock nuts as rod end of wing lift cylinder must slide freely in lift slot and bolt must rotate freely. Raise

and lower machine. Watch so hydraulic hoses do not tighten or get pinched, adjust hoses if necessary. Adjust wing

lift cylinder eye bolts so wings rest on center frame during transport. Tighten all Eye Bolts. Insure that cylinder attach

holes are aligned when eyebolts are tightened.

2-1

SET-UP INSTRUCTIONS – 14’ to 44’ HYDRAULIC FOLD IMPLEMENT