Sandvik Coromant Threading User Manual

Page 37

37

2. Applications – Thread milling

Coolant

• A thread mill does not require coolant

Cutting force

• A thread mill can make large threads in smaller machines due to

reduced cutting force

• Reduced cutting forces also make thread mills an ideal solution

for machining thin-walled components

Thread quality

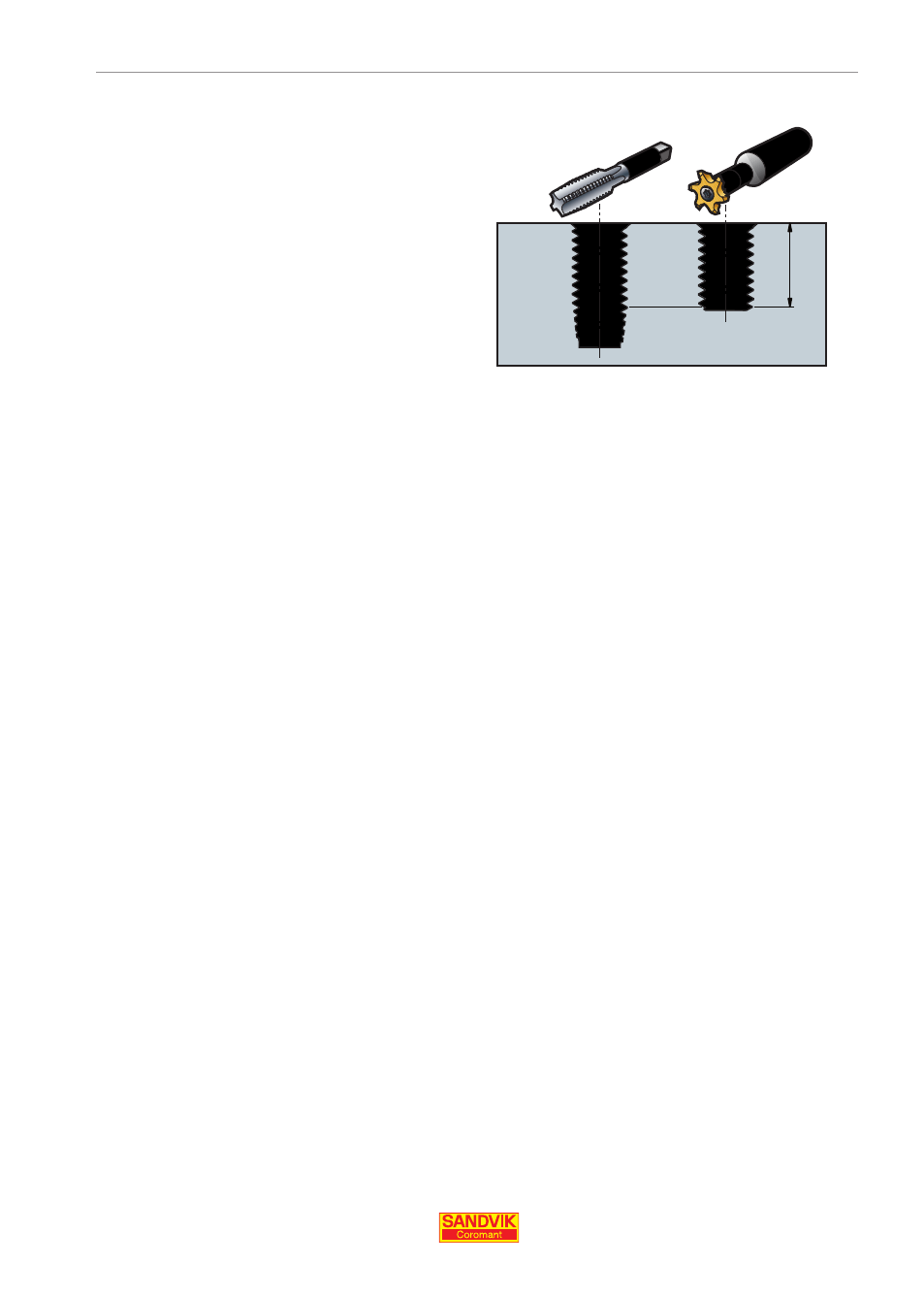

• Due to its shape, a thread mill can

achieve full-bottom threading in a blind

hole with no extra drill depth required

• A thread mill can be programmed with radius correction, allow-

wing for easy adjustment of the thread tolerance

• A thread mill minimizes the pre-machined hole diameter, com-

pared to a tap, so that threads can be produced with better

thread coverage