Insert tool life, Threading large profi les – Sandvik Coromant Threading User Manual

Page 33

33

STTCR/L

SDNCR/L, TR-D13NCN

2. Applications – Thread turning

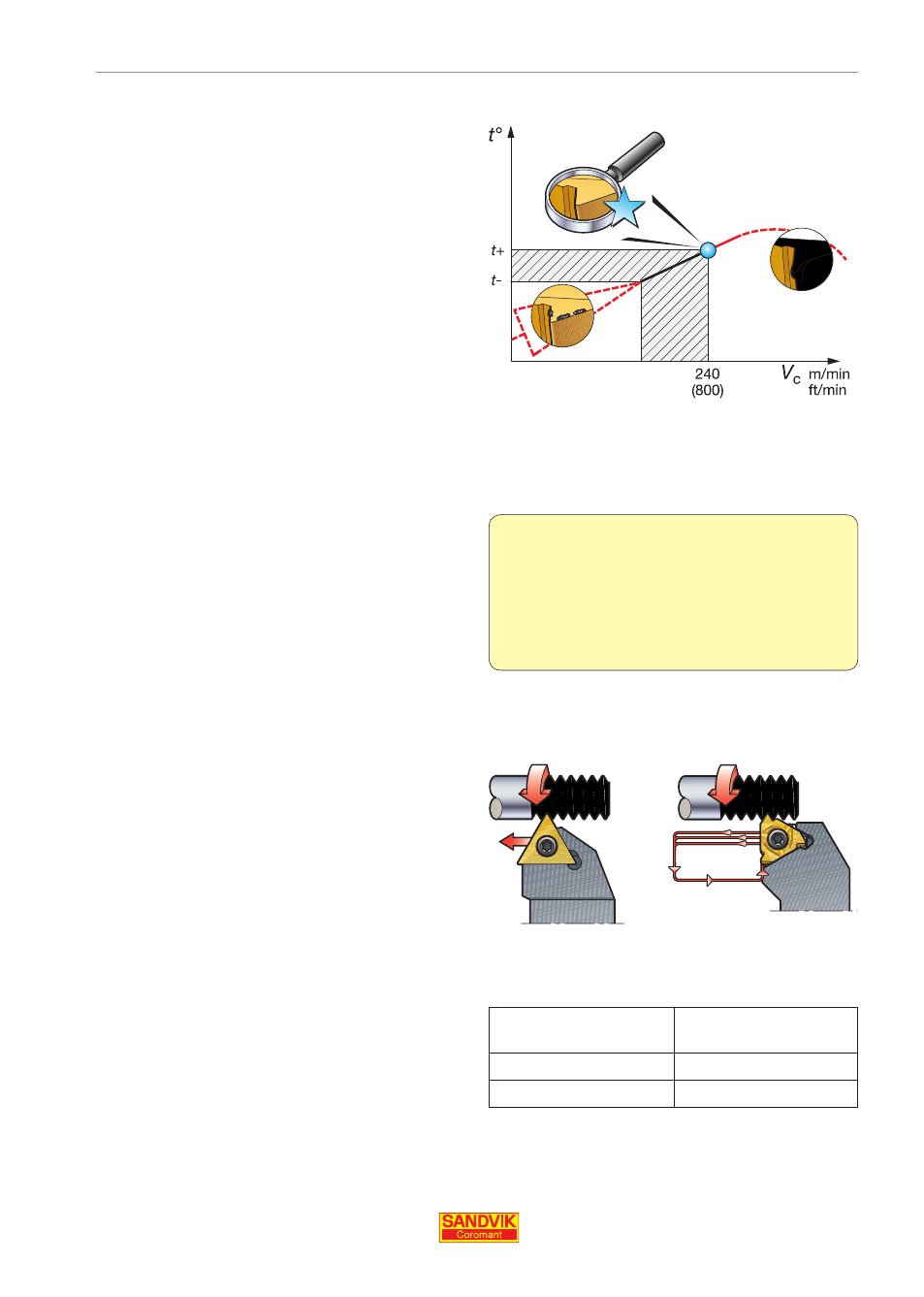

Insert tool life

Careful observation of the insert after

threading will allow you to achieve optimum

results regarding tool life, cutting speed and

thread quality. The main points to consider

are:

• When thread turning or thread milling at

low speed, the main problem is built-

up edge. To solve this, increase cutting

speed

• When thread turning at high speed,

plastic deformation of the tip is the main

problem. To solve this, decrease cutting

speed

• When thread milling, the main problem

is terminal cracks on the insert. This can

be addressed by increasing the coolant

volume or reducing the cutting speed

For information on the causes and solu-

tions to different forms of insert wear

see chapter 4, Troubleshooting (page

76).

Threading large profi les

When threading large profi les, it is advis-

able to use a conventional turning tool to

pre-machine the thread form before applying

the threading tool. This will extend the

life of the threading insert and give higher

thread quality.

When machining threads with small-radius

roots and crests, similar pre-machining can

also be applied by rough threading using

an insert with the same angle, but larger

nose radius. Allowance is then left for the

remaining fi nishing passes to be taken with

the right insert.

Pre-machining with CoroTurn 107

Profi les

Recommended

tool holder

60° MM, UN

55° WH