Sandvik Coromant Threading User Manual

Page 18

18

2. Applications – Thread turning

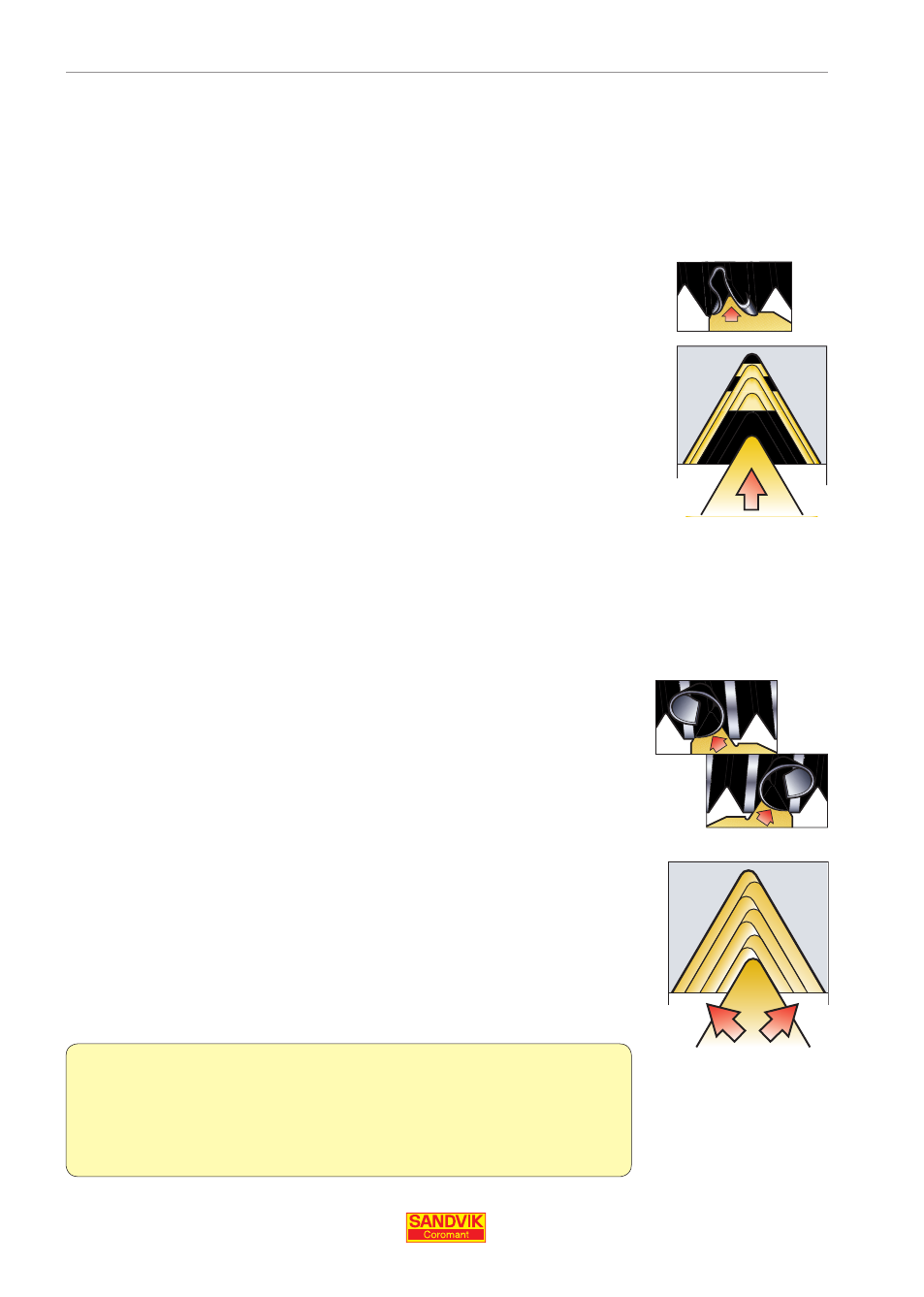

Radial infeed

The most commonly-used infeed method and the only one possible

on many non-CNC lathes.

• Produces a stiff, V-shaped chip, which is diffi cult to form

• Insert wear is even on both fl anks

• Suitable for fi ne pitches

• Insert tip is exposed to high temperatures, restricting the

possible infeed depth

• Risk of vibration and poor chip control in large pitches

Incremental infeed - for pitches larger than 5 mm (5 t.p.i.)

This infeed type is the fi rst choice for larger thread profi les.

• Even insert wear and long tool life

• A- and F-geometries should be used

• Special CNC machine programme is required

Very large thread profi les can be pre-machined with a turning

tool, fi nishing passes can be made with the threading tool

For more information see page 33 (Threading large profi les).