Troubleshooting – Actron CP8218 User Manual

Page 6

2

3. Remove the warning light sender and install

the proper adapter fitting into the engine block.

If the proper adapter fitting was not included

with the gauge, obtain the CP7555 (NPT

threads) adapter set.

4. Insert the capillary tube tip into the adapters

hole and then tighten, with moderate pres-

sure only, the captive fitting (Diagram 1) into

the adapter. Do not over tighten. Sealing tape

or compound may be used on either connec-

tion.

5. Complete the mounting of the gauge.

6. Refill the fluid level to its normal level.

7. Start the engine and observe the fitting con-

nections for leaks and the gauge for proper

operation.

FOR ELECTRICAL GAUGES:

1. Drain the fluid level in the system to below

the senders mounting location, which is nor-

mally the factorys warning light sender lo-

cation.

2. Remove the warning light sender and insu-

late the end of the sender wire. Install the

proper adapter fitting (not included) into the

engine block, if needed. Obtain either the

CP7553 (NPT threads) or CP7573 (metric

threads) adapter set, if an adapter is needed.

3. Install the gauges sender into the warning

light senders mounting location in the engine

block.

4. Run a length of 18-gauge insulated copper

wire from the gauges mounting location to

the senders mounting location.

5. Attach the 18-gauge wire onto the top of the

gauges sender.

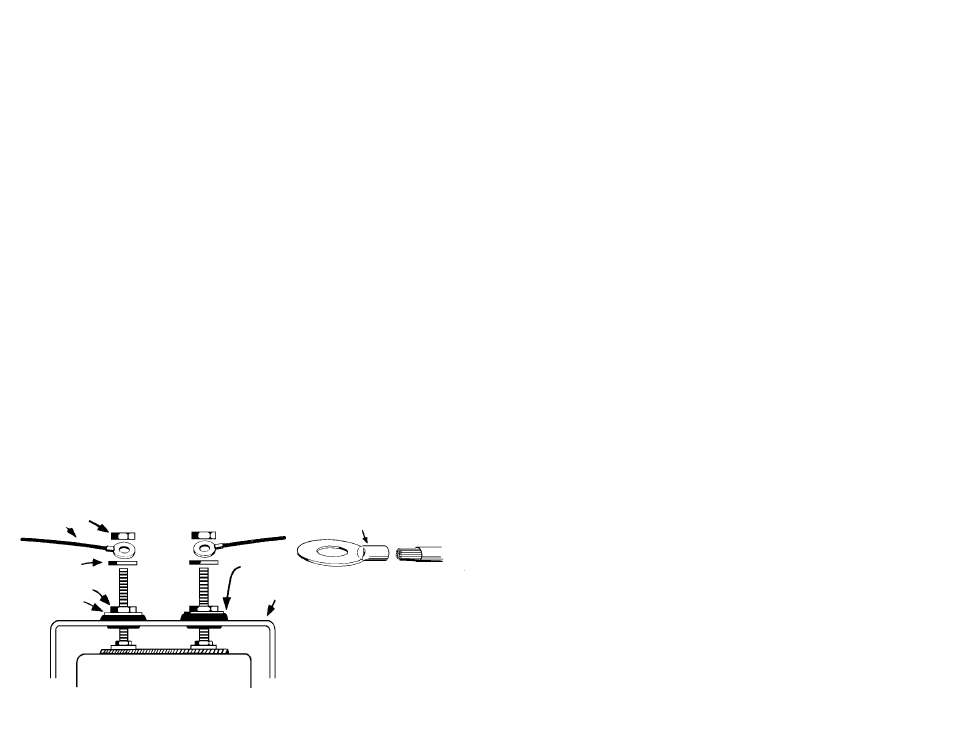

6. Facing the back of the gauge, the connection

post on the right is for the +12-volt power, the

center post is for the ground connection and

the left post is for the sender connection. Af-

ter you have mounted the gauge, connect the

sender wire to the left connection post as

shown in Diagram 2. Do not over tighten.

7. Connect one end of another length of 18-

gauge insulated copper wire to the center

connection post, as shown in Diagram 2 and

the other end of the wire to a good ground

source.

8. Connect a third length of 18-gauge insulated

copper wire to the right connection post as

shown in Diagram 2, and the other end of the

wire should be connected to the fuse box

where the wires will receive +12 volts of

power whenever the ignition key is in a

START, ON or ACCESSORY position.

9. Refill the fluid level to its normal level.

10. Start the engine and observe the fitting/

sender connections for leaks and the gauge

for proper operation.

TROUBLESHOOTING

If your electrical gauge reads lower than you would

expect, check all electrical connections, particu-

larly grounding connections. Any poor connec-

tion will increase electrical resistance resulting in

a false low reading.

Diagram 2

CLOSED-EYE CONECTOR

MAKE SURE CRIMP IS GOOD

GROMMET

U-BRACKET

NUT

WIRE

FLAT WASHER

NUT

WASHER

GAUGE

DO NOT LEAVE ANY HARDWARE OUT OF

THESE CONNECTIONS

7