Actron KAL2505 User Manual

Professional series, Compression test kit, Instructions for compression test procedure

1. Run the engine for about ten minutes or

until it reaches normal operating

temperature before performing the

compression test.

2. Stop the engine. Disconnect all the

spark plug wires and number them in the

order in which they were removed; this

makes them easy to identify for

reconnection.

3. Loosen all spark plugs about one turn,

but do not remove them. Use an air hose

or stiff brush to remove all the dirt from the

spark plug wells. Remove the spark plugs

and place them on a clean, flat surface in

the order in which they were removed. This

procedure will help to correlate any

compression or cylinder problems with the

condition of the plug from the particular

cylinder involved.

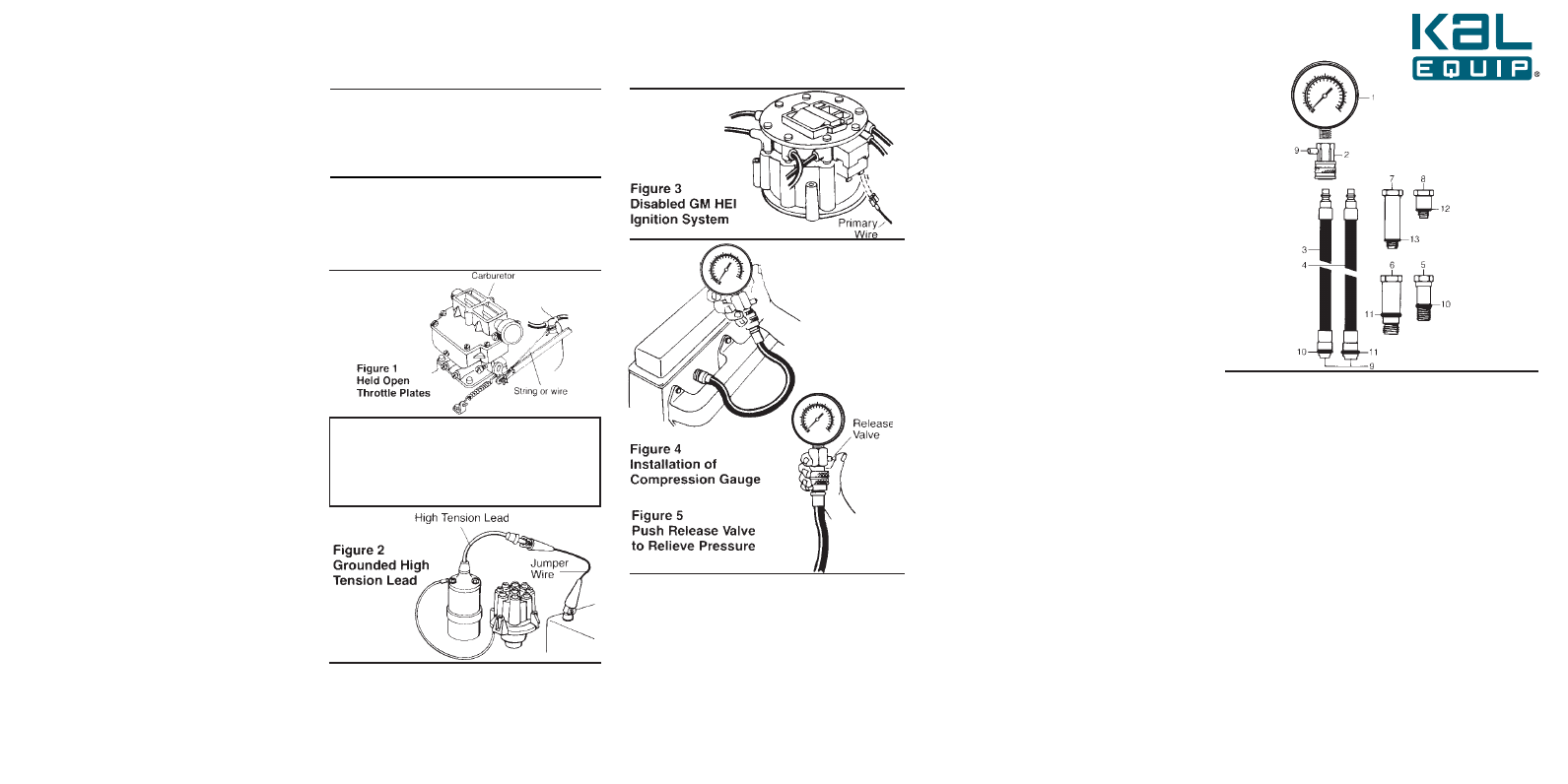

4. Remove the air filter and set the

carburetor throttle plates to the wide open

throttle position using a wooden block,

being careful not to damage the linkage or

carburetor components. See Figure 1.

5. Remove the high tension lead from the

center of the distributor and connect to

ground as shown in Figure 2. To disable

electronic ignition systems, disconnect the

electronic ignition module or remove the

primary battery terminal from the ignition

coil. On GM HEI V-8 and V-6, disconnect

the primary lead from the distributor cap

(Figure 3).

6. Disconnect the hose from the gauge.

Screw the spark plug adapter hose (Item 3,

Figure 6) into a spark plug well. Hand

tighten only DO NOT USE A WRENCH.

See Figure 4.

NOTE: On engines with long reach plugs,

use the long reach adapter (Items 5 and 6,

Fig. 6). Do not use the adapter in short

reach holes it may hit the top of the piston

and damage the engine.

7. Insert the spark plug hose into the

gauge by pulling up on the outer sleeve of

the gauges quick disconnect coupling and

allow it to snap back as the fitting engages

the adapter.

CAUTION!

Failure to return the carburetor

throttle plates to the closed position

before starting the engine can cause

serious engine damage.

8. Crank the engine for at least four

compression strokes or until the pressure

reading stops rising on the gauge.

9. Record the compression reading, then

push the side release valve to relieve the

pressure as shown in Figure 5. Repeat the

test. Record the reading, relieve the pressure,

remove the gauge from the hose, and

remove the hose from the spark plug well.

10.Reconnect the hose to the next spark

plug well to be tested and repeat steps 6

through 10 for the remainder of the

cylinders to be tested.

Test Results

1. On a normal cylinder, the gauge needle

should travel up-scale on each

compression stroke until it reaches a peak

value. All cylinders should indicate a

pressure that is within the vehicle

manufacturers specifications, and the

reading should not vary more than 10%

from cylinder to cylinder.

2. If the needle fails to travel up-scale as

described in Step 1, or if it remains at the

same value for several strokes and then starts

to climb, the cylinder has a sticking valve.

3. If the compression reading is

considerably higher than the vehicle

manufacturers specification, it indicates

carbon build-up in the cylinder.

4. If a reading on two adjacent cylinders is 20

psi (or more) lower than the other cylinders, a

defective head gasket is indicated. Water

(coolant) and oil may be found in the two

cylinders under these conditions.

5. If the readings are low or vary widely

between cylinders, pour a teaspoon of

S.A.E. grade 30 oil into each cylinder and

retest. If the readings increase considerably,

the fault may be due to poorly seated or

worn piston rings. If the readings remain

about the same, the valves and/or

associated components are the likely cause.

6. Clean, regap, and reinstall the spark

plugs in the same order in which they were

removed, or install new spark plugs.

Reconnect all spark plug wires in the proper

order. Remove the wooden block from the

carburetor throttle plates and make certain

they return to closed throttle position.

Reconnect the ignition system wiring, which

was disconnected in Step 5, TEST

PROCEDURE.

Compression Test Kit

Instructions for Compression Test Procedure

Key Part Number Description

1

0031-0255

Compression Gauge

2

0180-0772

Quick Disconnect Coupling

and Valve Assembly

3

0032-0112

14MM (Std) Spark Plug Hose

Assembly

4

0032-0113

18MM (Std) Spark Plug Hose

Assembly

5

0180-0895

14MM Long Reach Adapter

6

0180-0896

18MM Long Reach Adapter

7

0180-0894

12MM Adapter

8

0180-0893

10MM Adapter

9

*

Air valve (High Pressure)

10 *

O-Ring 14MM

11 *

O-Ring 18MM

12 *

O-Ring 10MM

13 *

O-Ring 12MM

14 0001-002-1644Instruction Label (not shown)

15 0400-1346

Carry Case (not shown)

includes item 14

16 *1000-2045

Repair Kit: includes five Air

Valves item 9, eight O-Rings

(two each) items 10, 11, 12, 13

Air Valve Tool (not shown)

0001-002-1644

Professional Series

Figure 6

Compression Gauge

Repair Parts

0

0

30

60

90

120

150

210

180

240

270

300

2

4

6

8 10 12

14

16

18

20

kPa x 100

Compression

Tester

0

0

30

60

90

120

150

210

180

240

270

300

2

4

6

8 10 12

14

16

18

20

kPa x 100

Compression

Tester

0

0

30

60

90

120

150

210

180

240

270

300

2

4

6

8

10 12

14

16

18

20

kPa x 1

00

Compression

Tester

©2003 Kal Equip.

All rights reserved.