Actron CP8218 User Manual

Oil pressure gauge - instructions, Precautions, Installation

1

OIL PRESSURE GAUGE - INSTRUCTIONS

WARNING: If your car is microprocessor (computer) controlled or has an electric cooling fan

refer to the section on the front cover titled MICROPROCESSOR CONTROLLED ENGINES.

Pressure gauges can measure the pressure

present in a system utilizing air or liquids. An elec-

trical pressure gauge is simpler and more versa-

tile for installation than a mechanical gauge but

is not quite as fast to respond to pressure

changes. The factory warning light sender can be

retained to operate the warning light with the use

of a T-Fitting which is commonly available at auto

parts stores and is manufactured by we.

PRECAUTIONS

1. Check the owners or service manual, or your

local dealer, to be sure that the normal pres-

sure during cold-start and fully-warmed op-

eration for your engine or air system are within

the gauge range.

2. Be sure the tubing kit for the mechanical

gauge is long enough for your application.

3. Follow the instructions carefully. A leak that

goes unnoticed may lead to serious engine

damage.

4. Do not use sealing tapes or compounds on

electrical senders. This will disturb their

grounding connection to the engine/system,

resulting in false low readings.

5. Be careful not to crimp the tubing while un-

rolling it. Do not use any section of tubing with

a crimp or kink in it. If the nylon tubing is a

little awkward to use because of being rolled,

heat it in boiling water and let the tubing cool

while it is unrolled.

INSTALLATION

Note: If you are planning to install an oil tempera-

ture gauge as well as an oil pressure gauge, read

the Note under INSTALLATION in TEMPERA-

TURE-WATER/OIL INSTRUCTIONS.

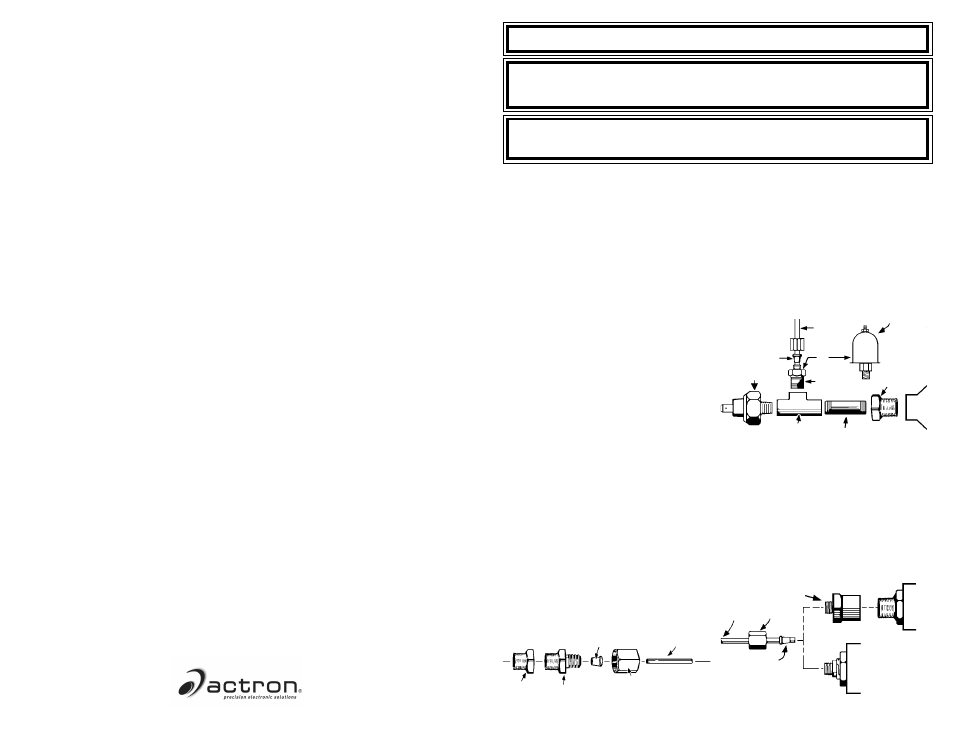

For Mechanical Gauges:

1. If you are monitoring a fluid system, drain the

fluid level to a level below the warning light

sender location.

2. Remove the warning light sender from the

engine and install the engine fitting in the same

location. If an adapter is required, first install

the adapter and then install the engine fitting.

3. Uncoil a few feet of tubing and slide the hex

nut and ferrule over the end of the tubbing

as in Diagram 1. Insert the tubbing into the

engine fitting, an then tighten the hex nut into

the engine fitting.

4. Optional T-Fitting (Diagram 2)- Install the nipple

into the T-Fitting and tighten the end of the

other nipple into the warning light sender lo-

cation. Install an adapter fitting first if needed.

In one of the two remaining openings in the

T-Fitting, insert the engine fitting and then

follow Step 3 to connect the pressure tub-

ing. Insert the warning light sender into the

remaining T-Fitting opening. Install an adapter

fitting first , if needed (we do not produce

metric fittings for the connection from a met-

ric warning light sender to the T-Fitting).

Diagram 3

HEX NUT ADAPTER

HEX NUT

TUBING

FERRULE

1/8 NPT

GAUGE

COMPRESSION

FITTING GAUGE

Diagram 1

FERRULE

TUBING

ADAPTER

ENGINE FITTING

HEX NUT

Diagram 2

TO MECHANICAL GAUGE

ELECTRICAL

GAUGE SENDER

HOSE

FERRULE

WARNING LIGHT

SENDER

T-FITTING

NIPPLE

ENGINE

BLOCK

ADAPTER

ENGINE

FITTING

OR

INDICADORES DE PRESION DE ACEITE/AIRE -

INSTRUCCIONES TENSIÓN 12 V

MANOMÈTRE DE PRESSION D'HUILE -

INSTRUCTIONS

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

8

ACTRON MANUFACTURING CO.

15825 Industrial Parkway

Cleveland, Ohio 44135

1-800-228-7667

©

2004 Actron Manufacturing Co.

All Rights Reserved.

0002-002-2404