Actron CP7005 User Manual

Dépannage, Installation, Precautions

10. Never install the captive fitting on the capillary

tube directly into the engine without an adapter,

as a proper seal will not be formed.

INSTALLATION

Note: If you are planning to use both an oil temperature

gauge and an oil pressure gauge, some modifications

may be necessary as there is only one available hole for

both senders. Since the temperature gauge cannot use

a T-fitting, we suggest that you install the oil temperature

sender into the oil pressure warning light sender location

in the engine block. Then obtain an adapter (which we do

not manufacture) used for oil coolers which will give you

an additional outlet for oil pressure.

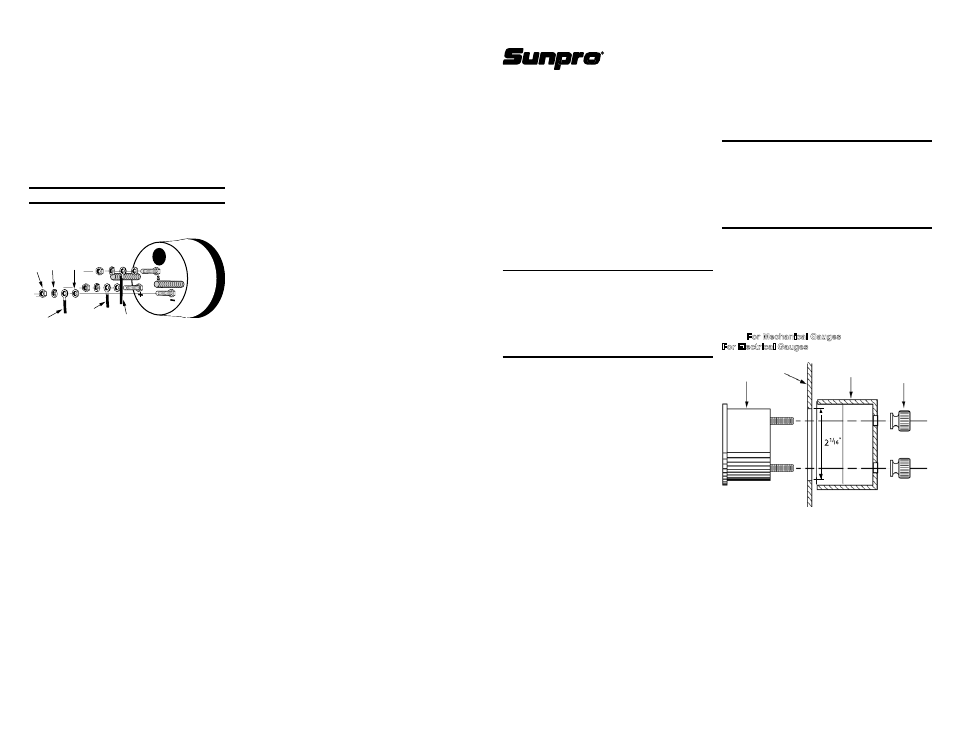

Gauge Installation

Make temporary test connection before permanently

mounting hardware or drilling holes.

This gauge can be mounted into any surface or

into a gauge pod. Refer to Figure 1.

Temperature gauges measure the temperature

of any liquid their sender tip is submerged in. An

electrical temperature gauge is simpler and more

versatile for installation than a mechanical gauge,

but is not quite as fast to respond to temperature

changes.

A temperature gauge requires that its sender tip

have a circulating flow around it to give an accu-

rate reading. For this reason, a T-fitting cannot be

used because it has no circulation therefore the

original warning light sender cannot be operated

off the same location. An additional location may

be available on the cylinder head, intake manifold,

or thermostat housing, but caution should be used

in that these locations may have different aver-

age temperatures than the original warning light

sender location.

NOTE: Some vehicles use electric cooling fans or micro-

processor engine controls that depend on readings from

the original equipment sending units for correct operation.

If your vehicle is one of these, then you CANNOT change

the OEM (original equipment manufacturer) sending

units(s). The only possible way to use non OEM sender

is to install it in a different location and leave the OEM

sender in its original location. Check with the vehicle’s

manufacturer or dealer to see if this is possible.

PRECAUTIONS

1. Disconnect the battery ground cable before

performing any electrical work.

2 Route all wiring away from linkages, engine

parts that become hot, or moving parts.

3. Never smoke while working on your vehicle

and always keep a fire extinguisher nearby.

It should be rated for gas/chemical/electrical

fires.

4. Never lay tools on top of the battery or wear

jewelry during electrical work to avoid severe

electrical shorts.

5. Locate and operate gauges so that driving

visibility is not compromised.

6. Do not overtighten the fittings or sender,

particularly for mechanical gauges. The

threads are designed to strip before the engine

component can be damaged. The fittings use

tapered self-sealing threads and do not require

extreme force to seal properly.

7. Do not use sealing tapes or compounds on

electrical senders as this will disturb their

grounding connection to the engine resulting

in false low readings.

8. Take caution when uncoiling and routing the

mechanical gauge’s capillary tubing so that you

do not bend it too sharply or flex it too often. Any

break in the inner tube will make the gauge non-

repairable. A replacement service is available

only at the factory service center.

9. Always install the adapter fitting into the engine

first and then tighten the captive fitting (Figure 3)

on the capillary tube to avoid twisting the tubing.

WATER/OIL AND TRANSMISSION

FLUID TEMPERATURE GAUGES

INSTALLATION INSTRUCTIONS

gAuge

DAshboARD

bRAckeT

NuTs

(kNuRLeD)

Figure 1

Gauge Mounting:

Do not install bracket and nuts until reaching step 6

in the For Mechanical Gauges section or step 10 in

For Electrical Gauges section.

1. Disconnect the battery ground cable before

performing any electrical work.

2. choose a location to mount the gauge where

it will be viewable from a normal driving

position.

3. If you are installing the gauge into a surface (for

example the dashboard) make a 2-1/16” hole

for the gauge. Do not accidentally cut any wires

or hoses. be sure there is clearance around the

hole for the gauge mounting bracket.

sunpro

®

15825 Industrial Parkway,

cleveland, oh 44135, u.s.A.

©2006 sPX corporation

sunpro

®

is a registered trademark of snap-on

®

corporation used under license to

sPX

®

corporation

0002-000-2908

For warranty information

contact us at:

1-800 228-7667 or www.sunpro.com

6. Après que vous ayez monté la mesure, reliez

le fil d’expéditeur au poteau de raccordement

de “s” comme représenté sur le schéma 4.

L’excédent ne serrent pas.

7. connectez une extrémité d’une autre longueur

de fil de calibre 18 en cuivre isolé sur la

borne “–”, comme illustré au schéma 4, et son

autre extrémité sur un point de bonne masse

électrique.

8. connectez une troisième longueur de fil de

calibre 18 en cuivre isolé sur la borne “+”,

comme illustré au schéma 4, et son autre

extrémité sur une borne de la boîte de fusibles

(12V) qui reste alimentée en tension que la clé

de contact soit dans n’importe quelle position

(sTART, oN, AccessoRY).

REMARQUE : Utilisez toute la visserie indiquée.

Schéma 4

Raccordements De Fil

INDIcATeuR

É

c

R

ou

R

o

ND

e

LL

e

PLA

Te

R

o

ND

e

LL

e

D

e

FR

e

INA

ge

FIL De 12V

FIL De

mAsse

ReNDemeNT

D’eXPÉDITeuR

9.Terminez le montage de la jauge.

10.Refaites l’appoint en fluide jusqu’au niveau

normal.

11. Démarrez le moteur, observez les connexions

de raccordement pour déceler des fuites

éventuelles et vérifiez le bon fonctionnement

du thermomètre.

DÉPANNAGE

si votre thermomètre électrique lit une valeur plus

faible que prévu, vérifiez toutes les connexions,

en particulier la mise à la masse. une mauvaise

connexion introduit une résistance de contact qui

provoque une ecture affaiblie erronée.