Actron KM2529 User Manual

Vehicle service information initial checks, Km2529 components, Fuel system checks

100

200

300

400

10

psi

40

60

kPa

50

30

20

Vehicle Service Information

INITIAL CHECKS

Fuel System Checks

Before doing any fuel system pressure

testing, check the following fuel sys-

tem components and correct any prob-

lems you may encounter:

1. Check fuel level and fuel tank vent-

ing (filler cap, etc.).

2. Check fuel for water or contamina-

tion.

3. Check fuel lines and hoses for dam-

age or looseness.

4. Check fuel system electrical fuses.

Pre-Testing Checks

1. Read Safety Guidelines.

2. Do a thorough visual and hands-

on inspection of the engine and

fuel system. Look for loose or

cracked electrical wiring, battery

cables, ignition wires, and fuel or

vacuum lines.

3. Verify that the battery is fully

charged and the fuel tank has an

adequate supply of fuel.

4. Verify that all fuel system fuses are

good.

5. Verify that the fuel vapor recovery

system and gas cap are in good

condition.

6. Verify that manifold vacuum is

within manufacturers specification

(typically 18-20 in. at idle).

7. Look for fuel leaks and wipe up any

spilled fuel immediately.

8. Has the vehicle been serviced

recently? Sometimes things get

reconnected in the wrong place, or

not at all.

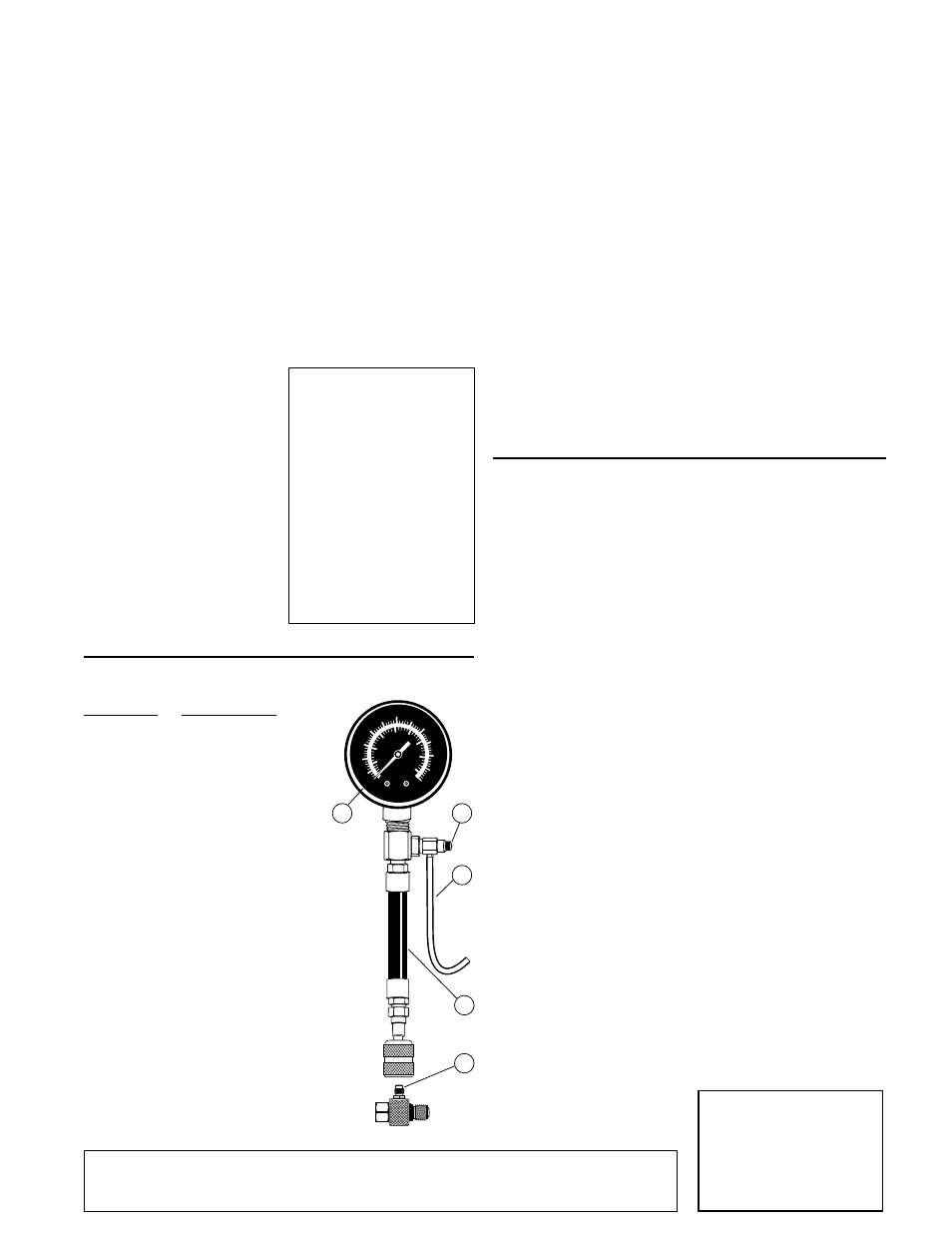

KM2529 Components

Part Number

Part Description

0180-000-1320

GM TBI adapter, M16 x 1.5

0032-000-0126

42 in. hose, gauge connector

fitting with pressure relief

button, and 72 in. plastic

tubing (bleed-off hose)

0031-000-0355

Fuel Pressure Gauge,

0-60 psi

1. Dial Face:

Measurement scale that shows

amount of fuel pressure present in fuel system.

2. Pressure Relief Button:

Used to relieve

fuel pressure in the gauge hose before

disconnecting the gauge from the fuel line.

3. Bleed-Off Hose:

A 6-ft. hose that bleeds off

fuel pressure when the pressure relief button is

pressed. Never use a bleed-off hose shorter than

6 ft.

IMPORTANT: Always make sure end of bleed-off

hose is in an approved fuel container during

testing and when bleeding off fuel pressure!

4. Gauge Hose:

Hose that carries fuel to the

gauge so that pressure can be measured.

5. GM TBI Test Adapter:

This adapter is used

to connect the gauge hose to GM TBI vehicles

NOT equipped with a fuel access valve test port

on the fuel rail.

Figure 1

The following is a list of publishers

who have manuals containing fuel

system testing information. Some

manuals may be available at auto

parts stores or your local public library.

For others, you need to write for avail-

ability and pricing, specifying the

make, model and year of your vehicle.

Vehicle Service Manuals

from General Motors Corp.:

Buick, Cadillac, Chevrolet, GEO,

GMC, Oldsmobile, & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

Saturn

Adistra Corporation

c/o Saturn Publications

101 Union St.

Post Office Box 1000

Plymouth, MI 48170

Vehicle Service Manuals:

Chilton Book Company

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92126

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Suitable manuals have titles such as:

“Electronic Engine Controls”

“Fuel Injection and Feedback

Carburetors”

“Fuel Injection and Electronic

Engine Controls”

1

3

2

4

5

9. Dont take shortcuts. Inspect wiring

which may be difficult to see

because of location beneath air

cleaner housings, alternators and

other components.

10. Inspect wiring harnesses for:

Contact with sharp edges (this

happens often).

Contact with hot surfaces, such

as exhaust manifolds.

Pinched, burned or chafed

insulation.

Proper routing and connections.

11. Check electrical connectors for:

Corrosion on pins.

Bent or damaged pins.

Contacts not properly seated in

housing.

NOTE: Problems with connectors

are common in the engine control

system. Inspect carefully. Note that

some connectors use a special

grease on the contact to prevent

corrosion. Do not wipe off! Obtain

extra grease, if needed, from your

vehicle dealer. It is a special type

for this purpose.

12. Check other vehicle systems:

IgnitionFor safety reasons,

most engine computers will not

deliver fuel without an ignition

spark.

Engine computerThe engine

computer has special drivers

which energize the fuel injectors.

These drivers are fragile and can

break easily. If you suspect a

computer driver problem, test by

replacing the computer with a

known good computer and retest.

General Safety Guidelines to

Follow When Working on Vehicles

To prevent accidents that could result in serious injury and/or

damage to your vehicle or test equipment, carefully follow

these safety rules and test procedures at all times when

working on vehicles:

DO NOT use Model KM2529 Fuel

Pressure Tester on Diesel or Flex

Fuel engines!

Always wear approved eye protec-

tion.

Always operate the vehicle in a well-

ventilated area. Do not inhale ex-

haust gases they are very poison-

ous!

Always keep yourself, tools and test

equipment away from all moving or

hot engine parts.

Always make sure the vehicle is in

Park (Automatic transmission) or

Neutral (manual transmission) and

that the parking brake is firmly set.

Block the drive wheels.

Never lay tools on vehicle battery.

You may short the terminals together

causing harm to yourself, the tools

or the battery.

Never smoke or have open flames

near vehicle. Vapors from gasoline

and charging battery are highly flam-

mable and explosive.

Never leave vehicle unattended

while running tests.

Always keep a fire extinguisher suit-

able for gasoline/electrical/chemical

fires handy.

Always use extreme caution when

working around the ignition coil, dis-

tributor cap, ignition wires, and

spark plugs. These components

contain high voltage when the en-

gine is running.

Always turn ignition key OFF when

connecting or disconnecting electri-

cal components, unless otherwise

instructed.

Always follow vehicle manu-

facturers warnings, cautions and

service procedures.

CAUTION:

Some vehicles are equipped

with safety air bags. You must

follow vehicle service manual

cautions when working

around the air bag compo-

nents or wiring. If these pre-

cautions are not followed, the

air bag may deploy unexpect-

edly, resulting in personal in-

jury. Note that the air bag can

still deploy several minutes

after the ignition key is off (or

even if the vehicle battery is

disconnected) because of a

special energy reserve mod-

ule.

All information, illustrations and specifications contained in this manual are based on the latest information available from industry

sources at the time of publication. No warranty (expressed or implied) can be made for its accuracy or completeness, nor is any respon-

sibility assumed by Actron Manufacturing Co. or anyone connected with it for loss or damages suffered through reliance on any informa-

tion contained in this manual or misuse of accompanying product. Actron Manufacturing Co. reserves the right to make changes at any

time to this manual or accompanying product without obligation to notify any person or organization of such changes.

One Year Warranty

If within one year from the date of pur-

chase this equipment fails due to de-

fect in materials or workmanship, return

it to Actron and Actron will repair it free

of charge.

This warranty gives you specific legal

rights, and you may also have other

rights which may vary from state to state.