Lokar EFI Throttle Cable User Manual

Efi throttle cable installation instructions

Building American Quality… With A Lifetime Warranty!

General Installation Notes:

Please read these instructions completely before beginning the

installation. If you have any questions please call.

Before beginning the installation, disconnect the negative battery

cable and use wheel chocks to block the vehicle's wheels. Do not

attempt to install or adjust this product while the engine is running.

Make sure the engine, transmission, body and frame are properly

grounded. We recommend applying anti-seize lubricant to all alumi-

num threads before final assembly. Do not over tighten.

NOTE: Lokar’s Throttle Cable Kits are designed to work with Lokar Throttle

Pedals and Throttle Cable Brackets. This throttle cable is designed to be

Cut-To-Fit for your particular application.

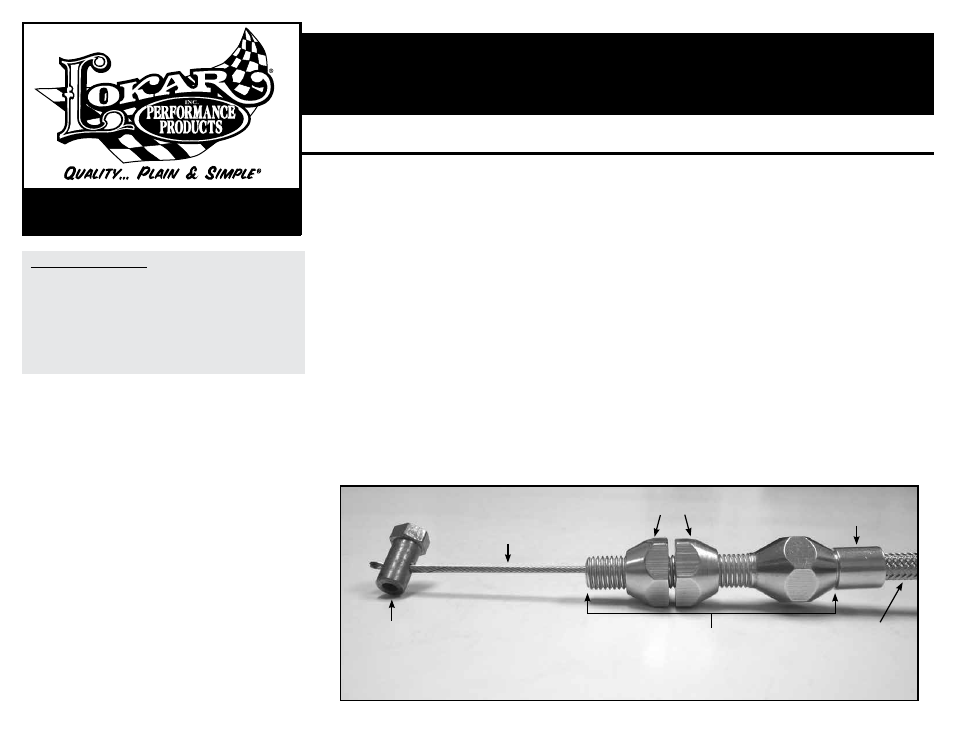

Refer to Figs. 1, 2 and 3 for the component names.

The GM Tuned-Port Injection (TPI) kit includes two throttle body fittings. The

aluminum throttle body fitting with two set screws fits early TPI systems up

through 1988 (Fig. 2). The brass throttle body fitting with one set screw is used

on 1989 and later TPI, LT1, and LT4 systems.

Step 1: Install the Lokar throttle pedal and throttle cable bracket if they are

not already installed, following the instructions that are provided with

those parts.

Step 2: The hole in the firewall must line up with the hole in the throttle

pedal. Determine exactly where the throttle cable needs to pass

through the firewall and drill a 5/16" hole.

Step 3: Remove the throttle body fitting and throttle cable adjuster from the

engine end of the new Lokar throttle cable. If you have the braided

stainless steel housing, make sure you

DO NOT remove the ferrule

from the cable housing. Pull the inner wire out of the cable housing.

Step 4: On the pedal end of the cable housing, remove the adjuster nut from

the firewall fitting. Insert the firewall fitting through the firewall from

the engine side, and then reinstall the adjuster nut.

Fig. 3

Step 5: Remove the front adjuster nut from the throttle cable adjuster and

insert the throttle cable adjuster into the throttle cable bracket

(bracket sold separately). Position the rear adjuster nut so that the

throttle cable bracket is approximately centered on the threaded part

of the throttle cable adjuster. Reinstall the front adjuster nut.

Fig. 4

TOLL FREE 1-877-469-7440 • (865) 966-2269 • FAX (865) 671-1999 • [email protected] • www.lokar.com

®

EFI Throttle Cable Installation Instructions

EFI Throttle Cable Installation Instructions

For GM TPI, LT1, LT4, Vortec, LS1, and Ram Jet 350

Ford EFI 1994-95, and Modular Engines

INS0068 Rev. 07/22/14

Page 1

© 2005 Lokar, Inc.

Fig. 1

For GM TPI, LT1, LT4, Vortec, LS1, and Ram Jet 350

Ford EFI 1994-95, and Modular Engines

Step 6: Make sure that the inner wire is removed from the cable housing. If the

cable housing is braided stainless steel, slide the ferrule up the housing

towards the firewall, away from the end that is being cut.

DO NOT remove the ferrule from the braided stainless steel housing!

If the cable housing is black universal, remove the ferrule.

Measure the distance between the throttle cable adjuster and the firewall

fitting. Add 2" to the measurement and cut the cable housing to that

length.

NOTE: Cable housing must not be straight between the throttle cable

adjuster and the firewall. There must be some slack to allow for engine

movement.

If the throttle cable has the braided stainless steel housing, wrap tape

around the area to be cut and use an abrasive cutoff wheel or fine-toothed

hacksaw. If the throttle cable has a black universal housing, cut the cable

housing with heavy duty 8" diagonal cutting pliers or a hacksaw. Lokar

recommends Klein brand Diagonal Cutting Pliers, # D2000-28 available at

The Home Depot or through W. W. Graingers, Part # 4A838.

After cutting the cable housing, put the ferrule back in place at the end

of the cable housing. Insert the cable housing and ferrule into the throttle

cable adjuster.

Step 7: Reinstall the inner wire into the cable housing from inside the passenger

compartment. Connect the clevis on the new Lokar throttle cable to the

throttle pedal.

NOTE: If you are using a factory style pedal with a ball type connection,

the clevis can be removed by simply sliding it off of the inner wire before

you install the inner wire into the cable housing.

Step 8: Depress the throttle pedal to the floor and hold the throttle body at

the wide open throttle position. Pull all the slack out of the inner

wire. Mark the inner wire at the spot that the throttle body fitting

attaches to the throttle lever or fits into the hole on the pulley.

Step 9: On 1988 and earlier TPI with a throttle lever, cut the inner wire 1/4"

shorter than the mark. On all others with a throttle pulley, cut the

inner wire 1/4" longer than the mark.

MAKE SURE you are not cutting

the inner wire too short! Install the throttle body fitting onto the end

of the inner wire and tighten the set screw(s).

Step 10: Still holding the throttle wide open, release the throttle pedal so

that it creates slack in the inner wire. Attach the throttle body

fitting to the throttle lever or insert it into the slot or groove in

the pulley.

Step 11: Release the throttle. Take any slack out of the inner wire with the

adjuster nuts. The throttle cable adjustment should allow

the throttle to close fully, and the pedal should touch the floor

at the same time the throttle reaches wide open.

NOTE: Check to

make sure there is no binding of the throttle cable at both the

throttle pedal and at the throttle linkage before starting the engine

or driving the vehicle.

See

Fig. 5 for an example of the throttle cable installed on a GM

LS1 engine,

Fig. 6 for an early TPI installation, and Fig. 7 for an

LT1/LT4 installation.

Inner Wire

Throttle Body Fitting

(Varies per Application)

Ferrule

Cable

Housing

Throttle Cable

Adjuster

All Except 1988 and Earlier GM TPI

Adjuster Nuts