Lokar Ford AOD Hi-Tech Kickdown Kit User Manual

Page 3

Ford AOD Hi-Tech Kickdown Kit Installation Instructions

Page 3

T.V. Cable Pressure Adjustment

WARNING: Failure to perform the following T.V. Pressure Adjustment procedure

may cause your transmission to fail prematurely, possibly within only the first

few miles!

NOTE: Adjustment of the T.V. cable must be done with the carburetor off of

fast idle and the engine at normal operating temperature.

If the idle

speed setting on the carburetor is ever changed, the T.V. cable adjust-

ment will need to be re-checked and adjusted.

Step 10: On the passenger side of the transmission near the tailhousing, you

will find three test ports. The TV test port is the one in the middle.

Fig. 9 Remove the block off plug from the T.V. test port, and con-

nect an oil pressure gauge with hose (not included) using a 1/8"

NPT fitting. The oil pressure gauge needs to be capable of handling

at least 60 PSI and be marked with individual PSI readings all the

way down to zero.

Step 11: Pull forward on the cable end stop at the engine end of the T.V.

cable in order to create some clearance between the cable end stop

and the kickdown throttle body fitting. Insert the slotted end of the

supplied T.V. cable gauge tool between the cable end stop and the

kickdown throttle body fitting so that the T.V. cable inner wire is

inside the slot on the tool.

Fig. 10

Step 12: Operate the engine until it reaches normal operating tempera-

ture. The transmission fluid temperature should be approximately

100º-150º F (38º-70º C). Do not perform the pressure adjustment

procedure if the transmission fluid is cold or is too hot to touch.

Step 13: Set the parking brake and place the shifter in NEUTRAL. With the

T.V. cable gauge tool in place and the engine at warm idle, the T.V.

pressure should be 35 psi.

Note: DO NOT check or set TV pressure in PARK, the pressure is

different!

Step 14: Adjust as needed to get the T.V. pressure to 35 PSI. Make major

adjustments by moving the cable end stop one direction or the

other, and make minor adjustments at the two nuts on the T.V.

cable adjuster.

Step 15: Once you have the cable adjusted so that the pressure gauge reads

35 PSI with the T.V. cable gauge tool inserted, remove the T.V.

cable gauge tool.

Step 16: Allow the T.V. cable to return to its normal idle position. With the

engine still idling in

NEUTRAL, T.V. pressure must be at or near

zero. If not, reinstall the T.V. cable gauge tool. Repeat steps 11

through 15, but set T.V. pressure to a value between 30 PSI and

34 PSI. Remove the T.V. cable gauge tool and recheck T.V. pres-

sure to determine if it is at or near zero.

Step 17: Once you have achieved the pressures described above, with the

engine still idling and the transmission in

NEUTRAL, watch the pres-

sure gauge while you slowly begin to open the throttle. The T.V.

pressure should begin to rise immediately when the throttle begins

to move. If not, then remove any slack in the T.V. cable until the

pressure does begin to rise immediately when the throttle is moved.

Then repeat

Steps 11-17. If there is slack in the T.V. cable, it can

damage your transmission!

Step 18: Disconnect the pressure gauge and re-install the plug in the T.V.

test port.

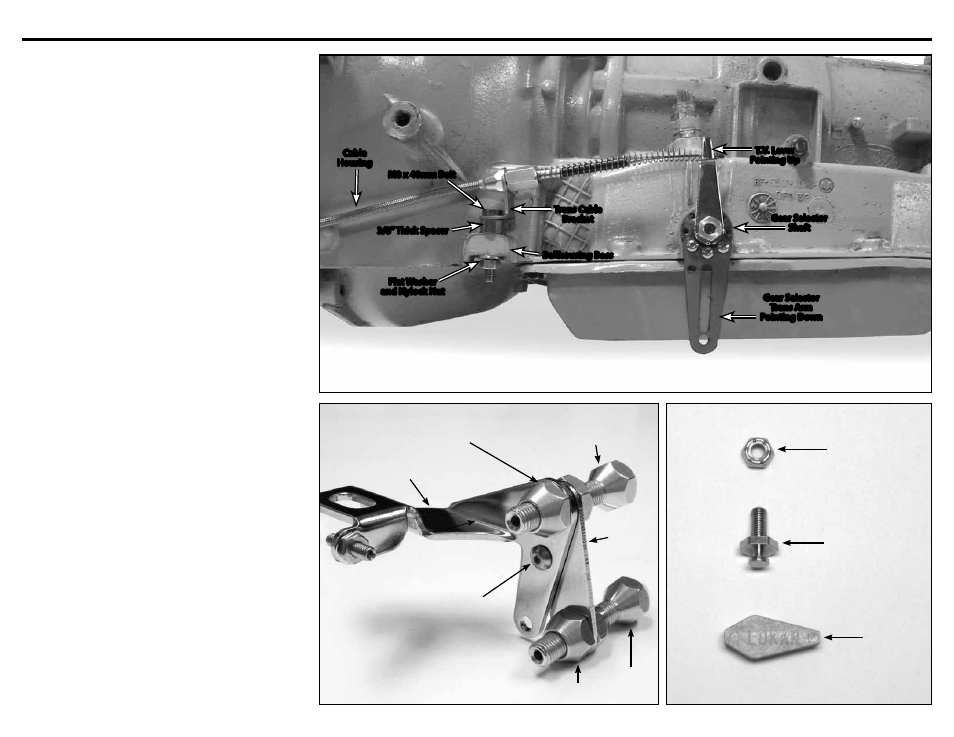

Transmission shown with Gear Selector Trans Arm

pointed down and T.V. Cable installed

Fig. 4

Gear Selector

Shaft

Gear Selector

Trans Arm

Pointing Down

Flat Washer

and Nylock Nut

Cable

Housing

3/8" Thick Spacer

M8 x 40mm Bolt

Bellhousing Boss

Trans Cable

Bracket

T.V. Lever

Pointing Up

Carburetor

Bracket

(not included)

#8-32 x 1/2"

Button Head Bolt

with Nylock Nut

Adjuster Nut

(not included)

Throttle Cable

Adjuster

(not included)

Kickdown

Mounting

Bracket

1/4" – 28 Nylock

Jam Nut

Hex Carb Fitting

Kickdown

Throttle Body

Fitting

T.V. Cable

Adjuster

Adjuster Nut

Fig. 5

Fig. 6