Lokar Blower Drive Kickdown Cable User Manual

Page 2

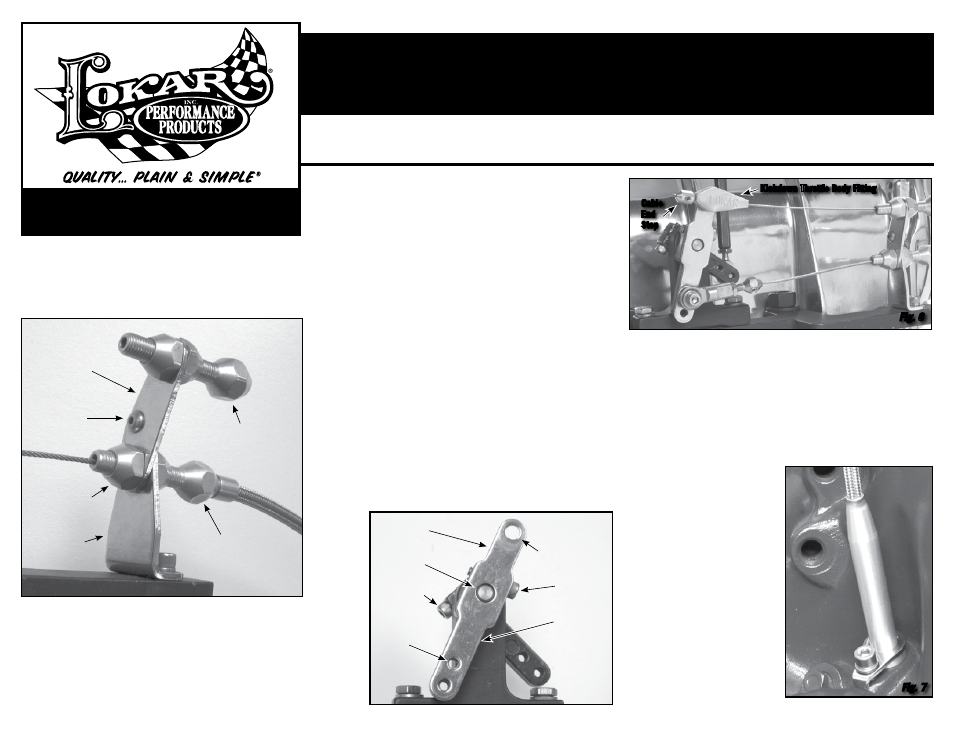

Step 11: Install hex carb fitting and nylock jam nut with kickdown throttle

body fitting in the top hole on the blower kickdown bracket.

Tighten the nylock jam nut.

Step 12: Install inner wire through the kickdown throttle body fitting, and

slide the cable end stop onto the inner wire. Position the cable end

stop approximately 2” from the kickdown throttle body fitting and

snug down the set screw just enough to keep it from sliding off.

Step 13: Make final adjustments by holding throttle to wide open and pull-

ing the kickdown inner cable as tight as possible. Move cable end

stop up against the kickdown throttle body fitting and tighten set

screw. When the blower drive kickdown cable is properly adjusted

you will be able to open the throttle to the wide open position and

there will be no slack in

the inner wire.

Double check to be sure

that all carburetor, throt-

tle and kickdown linkage

operates freely without

binding, then test drive.

Once kickdown cable is

correctly adjusted and

operating properly you

can cut off the excess

inner wire, leaving about

1" extending beyond the

cable end stop to allow

for future adjustment.

When finished, the

installation should look

like

Fig. 6 and Fig. 7.

© 2012 Lokar, Inc.

INS0124

Rev. 05/23/12

Page 2

Building American Quality… With A Lifetime Warranty!

10924 Murdock Dr. • Knoxville, TN 37932

TOLL FREE 1-877-469-7440 • (865) 966-2269 • FAX (865) 671-1999 • [email protected] • www.lokar.com

®

Blower Drive Kickdown Cable Installation Instructions

Blower Drive Kickdown Cable Installation Instructions

For TH200, TH350, TH700-R4, TH200-4R, and 4L60

For TH200, TH350, TH700-R4, TH200-4R, and 4L60

Step 5: Route the throttle cable inner wire and the throttle cable adjuster

through the bottom hole in the kickdown mounting bracket.

Reinstall the front throttle cable adjuster nut, and connect (or

reconnect) the throttle cable inner wire. Attach kickdown mount-

ing bracket to blower cable bracket as shown in

Fig. 4, using the

#8-32 x 1/2” button head bolt and nylock nut.

Step 6: Route kickdown cable housing up to the kickdown cable

adjuster. If the cable housing is braided stainless steel, slide the

ferrule back towards the transmission, away from the end that is

being cut. DO NOT remove the ferrule from a braided stainless

steel housing! If the housing is black universal, remove the fer-

rule. Add 1" extra and cut the kickdown cable housing to desired

length. Make sure that the inner wire is removed from the cable

housing before cutting!

Step 6: (continued) If the cable housing is braided stainless steel, wrap tape

around the area to be cut and use an abrasive cutoff saw or fine-

toothed hacksaw. If the kickdown cable has a black universal housing,

cut the cable housing with heavy duty 8” diagonal cutting pliers or a

hacksaw. Lokar recommends Klein brand Diagonal Cutting Pliers, #

D2000-28 available at The Home Depot or through W. W. Graingers,

Part # 4A838.

After cutting the cable housing, put the ferrule back in place at the

end of the cable housing. Insert the cable housing and ferrule into the

kickdown cable adjuster.

Step 7: Remove the kickdown cable housing from the transmission. Re-install

the inner wire into the blower drive kickdown cable housing.

Step 8: On the trans tube at the transmission end of the blower drive kick-

down cable there will be either one or two o-ring grooves. TH350 &

TH200 use one o-ring, and the TH700R4, TH200-4R, and 4L60 use

two o-rings. Lightly lubricate the kickdown cable o-ring(s) with clean

transmission fluid and slide the o-ring(s) into the groove(s) on the trans

tube. To help prevent leakage add a small amount of silicone sealant

(RTV) around the trans tube above the top o-ring.

Fig. 2

Step 9: Insert the hook on the transmission kickdown rod into the hole on the

end of the kickdown cable inner wire. Install the transmission tube into

the transmission, and secure with the tube hold down clip and bolt.

Step 10: Install the blower kickdown bracket onto the splined arm on the

blower throttle linkage, with the two holes at the bottom. The blower

kickdown bracket is positioned by the blower linkage pivot shaft and

attached using the throttle cable bolt. If the blower linkage pivot

shaft does not protrude out far enough to align the blower kickdown

bracket, it will be necessary to adjust the position of the splined arms

on the pivot shaft by loosening the pinch bolts and repositioning parts

as needed.

Fig. 5

Kickdown

Mounting

Bracket

Blower Kickdown

Bracket

Hex Carb Fitting

with Nylock Jam

Nut goes here

Blower Linkage

Pivot Shaft

Pinch Bolt

Pinch Bolt

Splined Arm

(Behind Blower

Kickdown Bracket)

Throttle Cable

Bolt goes here

Kickdown Cable

Adjuster

Throttle Cable

Adjuster

#8-32 Button

Head Bolt with

Nylock Nut

Front Throttle

Cable Adjuster Nut

Blower Cable

Bracket

Fig. 4

Fig. 5

Cable

End

Stop

Fig. 6

Fig. 7

Kickdown Throttle Body Fitting