Lokar Anchor-Tight Locking Flexible Transmission Dipstick User Manual

Lokar For the car

Building American Quality… With A Lifetime Warranty!

General Installation Notes:

Please read instructions completely before beginning the installation. If you

have any questions please call.

Disconnect negative battery cable and set parking brake or chock vehicle

wheels before beginning the installation.

TOLL FREE 1-877-469-7440 • [email protected] • www.lokar.com

®

Anchor-Tight Locking Flexible Transmission Dipstick

Installation Instructions

INS0075 Rev. 01/23/14

Page 1

© 2007 Lokar, Inc.

Anchor-Tight Locking Flexible Transmission Dipstick

Installation Instructions

NOTE: The dipstick is designed for transmissions with “push in” style dipsticks.

Each transmission dipstick has been calibrated for the specific transmis-

sion application.

The standard

Firewall Mount dipstick is approximately 26" in length, but can

be special ordered in lengths up to 48". It allows the dipstick to be mounted

to the firewall or anywhere desired in the engine compartment. The

Transmount

dipstick varies in length according to the transmission application and mounts

on the bell housing. The Firewall Mount is the most versatile and is used where

there is little room in the engine compartment.

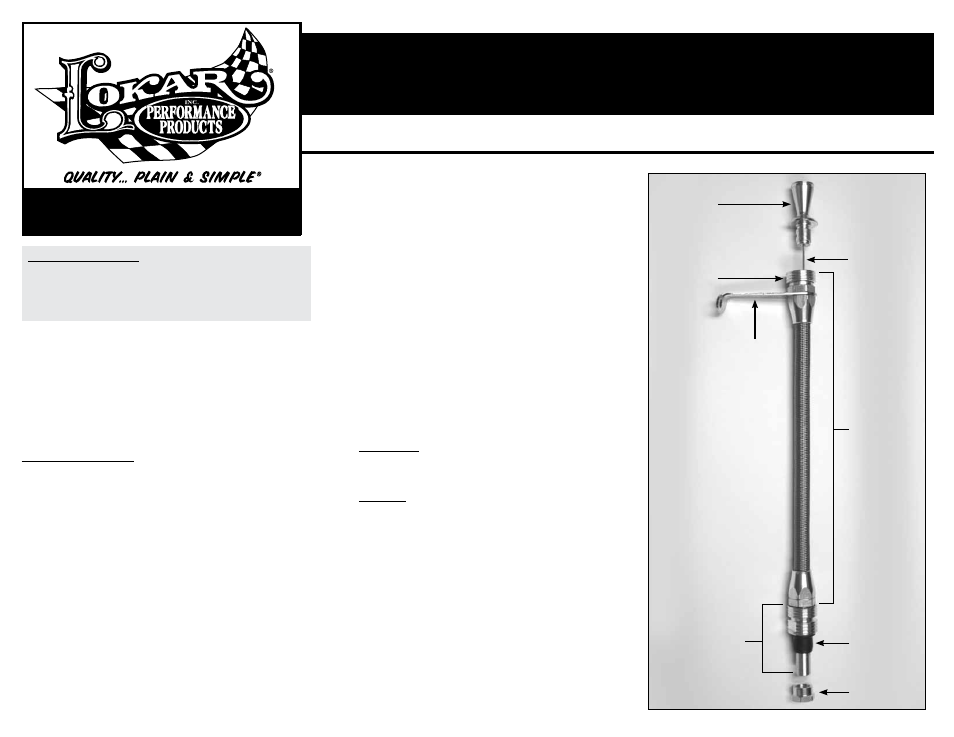

Refer to Fig. 1 for the component names.

How to Use Locking Mechanism:

To insert or remove the dipstick handle and inner measuring cable, slide the

spring-loaded retaining sleeve downwards away from the handle and hold while

inserting or removing the handle and inner measuring cable. See

Fig. 2.

The Lokar Transmount and Firewall Mount dipstick tubes also have a locking

quick disconnect fitting on the bottom so that you can remove the dipstick

tube assembly for easier installation or removal of the transmission. To remove

the dipstick tube assembly from the transmission, push the spring loaded

retaining sleeve downwards and hold, while pulling up on the dipstick tube

assembly.

A transmission storage plug is included with the Transmount and Firewall

Mount dipsticks. Place this storage plug into the pan fitting when the transmis-

sion is being transported, installed or removed. This helps prevent fluid spill-

age.

Fig. 3 Additional pan fittings and plugs are available separately.

NOTE: DO NOT remove any nuts securing the braided stainless steel hose to the

dipstick tube assembly.

DO NOT disassemble the spring loaded retaining

sleeve mechanism.

Step 1: Clean the dipstick opening on the transmission, making sure it is free

from all debris or burrs.

Step 2: Drain the transmission fluid and remove the transmission fluid pan.

Step 3: Remove the pan fitting from the bottom end of the new Lokar dipstick

tube assembly. Remove the pan nut from the pan fitting. Lubricate the

rubber push-in grommet with clean transmission fluid. Install the pan

fitting and rubber push-in grommet (as received) into the transmission.

(This should be a tight fit). Screw the pan nut onto the pan fitting and

torque to 20 ft.-lbs.

Do Not Over Tighten! Fig. 4

TH400 Note: When installing the pan nut on a TH400, rotate the nut

until one of the flats on the nut is parallel to the pan rail. This will allow

the pan to be installed without interfering with the nut.

Powerglide Note: A tapered washer is supplied with all Powerglide dip-

sticks. This washer needs to be installed on the pan fitting and rotated

until the pan nut has a square surface to tighten up against. Torque to

20 ft.-lbs.

Do Not Over Tighten!

Ford and Chrysler Note: Some transmission cases have limited space in

this area and there will not be enough room to turn the nut or retaining

tab. You will need to screw the pan fitting into the nut or retaining tab

instead. This can be done by using the supplied 1/2" hex installation

tool. Insert the end of the installation tool with the largest chamfer into

the top of the pan fitting. Push it down until it slips past the o-ring

inside the fitting. Use a 1/2" socket to rotate the pan fitting into the nut

or retaining tab. Torque to 20 ft.-lbs.

Do Not Over Tighten!

Step 4: Insert the dipstick tube assembly into the pan fitting, making sure it

clicks into place. The retaining sleeve

MUST be pushed down in order

for the dipstick tube assembly to be fully inserted.

Step 5: FiREwALL MOUNT, Route the dipstick tube assembly to the desired loca-

tion (firewall, inner fender, etc.) and install the mounting bracket using

two screws of your choice (not included). Make sure the dipstick tube

assembly is not touching the exhaust at any point.

Step 5: TRANSMOUNT, Install the mounting bracket onto the bell housing using

the appropriate existing bell housing bolt. Make sure the dipstick tube

assembly is not touching the exhaust at any point.

Powerglide Note: Some aftermarket Powerglide cases require a spacer

to be used between the case and the Lokar mounting bracket. A 3/16"

aluminum spacer is provided in the kit for this purpose. Also verify that

the mounting bolt being used to hold the bracket and spacer in place is

the correct length.

Step 6: Using an automotive funnel, fill the transmission with the appropriate

amount of fluid. Return the dipstick handle and inner measuring cable

into the dipstick tube assembly, being sure that the handle is snapped

down in its locked position when checking the fluid level. The retaining

sleeve

MUST be pushed down in order for the handle and inner measur-

ing cable to be fully inserted. This will ensure that the transmission

fluid is at the appropriate level.

Fig. 5

NOTE: Be sure to follow the transmission manufacturers recommended

procedure when checking the transmission fluid level (engine running or

not, fluid hot or cold, shifter in a particular position, etc.).

Pan Nut

Pan

Fitting

Mounting

Bracket

Typical transmount

dipstick shown as

an example only.

The mounting

bracket and pan

fitting will vary by

application.

Retaining

Sleeve

Handle

Grommet

Dipstick

Tube

Assembly

Inner

Measuring

Cable

Fig. 1

®

®