BMR Suspension KM008-1 User Manual

BMR Suspension For the car

TUBULAR K-MEMBER AND A-ARM INSTALLATION INSTRUCTIONS

Part #’s: AA007, AA007K, AA008, KM006, KM006-1, KM007, KM007-1, KM008, KM008-1

While it is possible to perform this installation in the driveway, we consider it to be a moderate-to-difficult install. Professional

installation with a 4-post service lift is highly recommended.

• NOTE: This installation requires the removal of coil springs. Improper spring removal techniques can result in severe

injury or death. If you do not have experience in this area or feel uncomfortable with this installation, an experienced

technician is recommended.

• NOTE: If you are using our LS1 tubular K-member (Part #KM008, KM008-1) it is assumed that the original engine has

been previously removed and it is up to the installer to modify these instructions accordingly.

• NOTE: These particular K-members are not compatible with factory A-arms. Before proceeding with this installation, verify

that you have the correct part numbers for your application.

INSTALLATION:

1. Disconnect battery.

2. Lift vehicle and support with stands under the frame rails. Vehicle needs to be supported high enough to lower and install the

K-member. Remove both front tires.

3. Remove both cotter pins on the outer tie rod ends and loosen the castle nuts with a 19mm wrench. Knock the tie rod loose

and swing both tie rods out of the way.

4. Using a 13mm wrench and 13mm socket, remove both outer sway bar links and swing the sway bar down, out of the way.

5. Remove the cotter pin on the lower ball joint and loosen the castle nut using a 15/16” wrench. Loosen the nut until it is flush

with the top of the ball joint stud. DO NOT REMOVE NUT.

6. Using a pickle fork, break the ball joint loose from the spindle. Position a hydraulic jack under the A-arm and release tension

from the castle nut. Remove nut and carefully lower the A-arm, releasing spring tension slowly.

7. Using a large pry-bar, carefully pop the spring out of the A-arm pocket. Remove spring.

8. Repeat steps 5-7 on the other side.

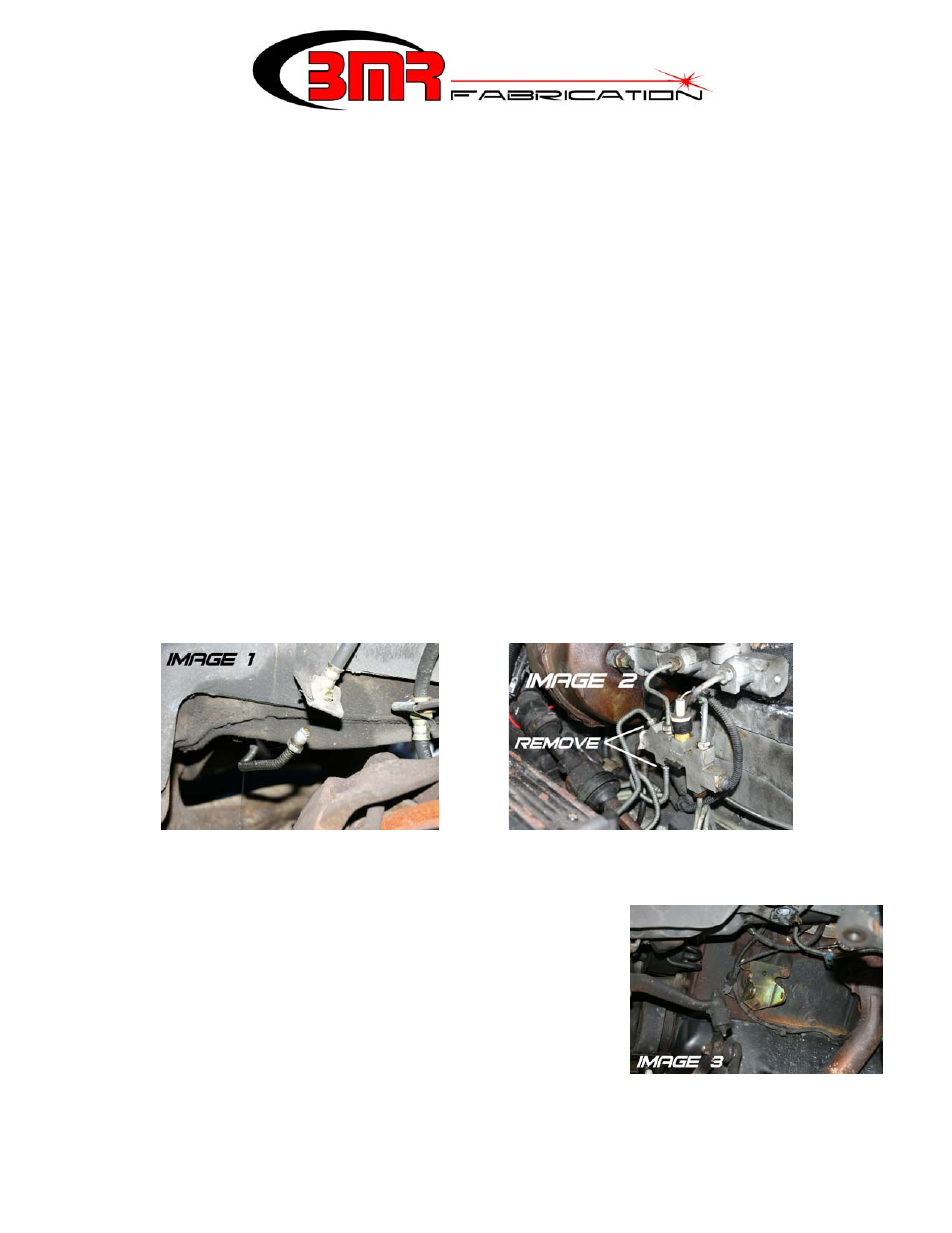

9. Locate the brake lines in the outer wheel wells (See Image 1). Place a catch can and rags under the connection and loosen the

lines with a 12mm wrench. Using the same wrench, remove the two brake lines at the rear of the proportioning valve (See

Image 2). There is also one retainer that holds the rear brake line to the K-member. It is located directly below the master

cylinder and proportioning valve. Remove this retainer using a 10mm socket.

10. Using a 16mm wrench and an 18mm socket, remove both motor mount cross bolts.

11. Support the motor with a hydraulic jack or stand. Verify that the motor is stable before proceeding.

12. Remove all six K-member bolts using an 18mm socket. Using a 15mm socket, remove the front K-member triangular

supports that bolt to the frame rails.

13. Before lowering the K-member/A-arm assembly, make sure that all brake lines

have sufficient room to lower with the K-member. It may be necessary to bend

the brake lines slightly to simplify removing the K-member. Lower the K-

member/A-arm assembly slowly being careful not to damage any of the brake

lines.

14. Using a 14mm socket, remove the factory motor mount “clamshells” and install

the BMR/Moroso clamshells (See Image 3).

15. Before installing the BMR K-member, it is necessary to determine which A-

arms you will be using. If using the factory springs, it is necessary to use BMR

A-arms (PART #AA008) and BMR Upper Spring Pockets (PART #USP001). If converting to a coil-over spring setup, it is

necessary to use the BMR A-arm Kit (PART #AA007K) or equivalent.

PAGE 1