Problem probable cause solution – AirSep MN138-1 H User Manual

Page 35

29

MN138-1 Rev H

02/14

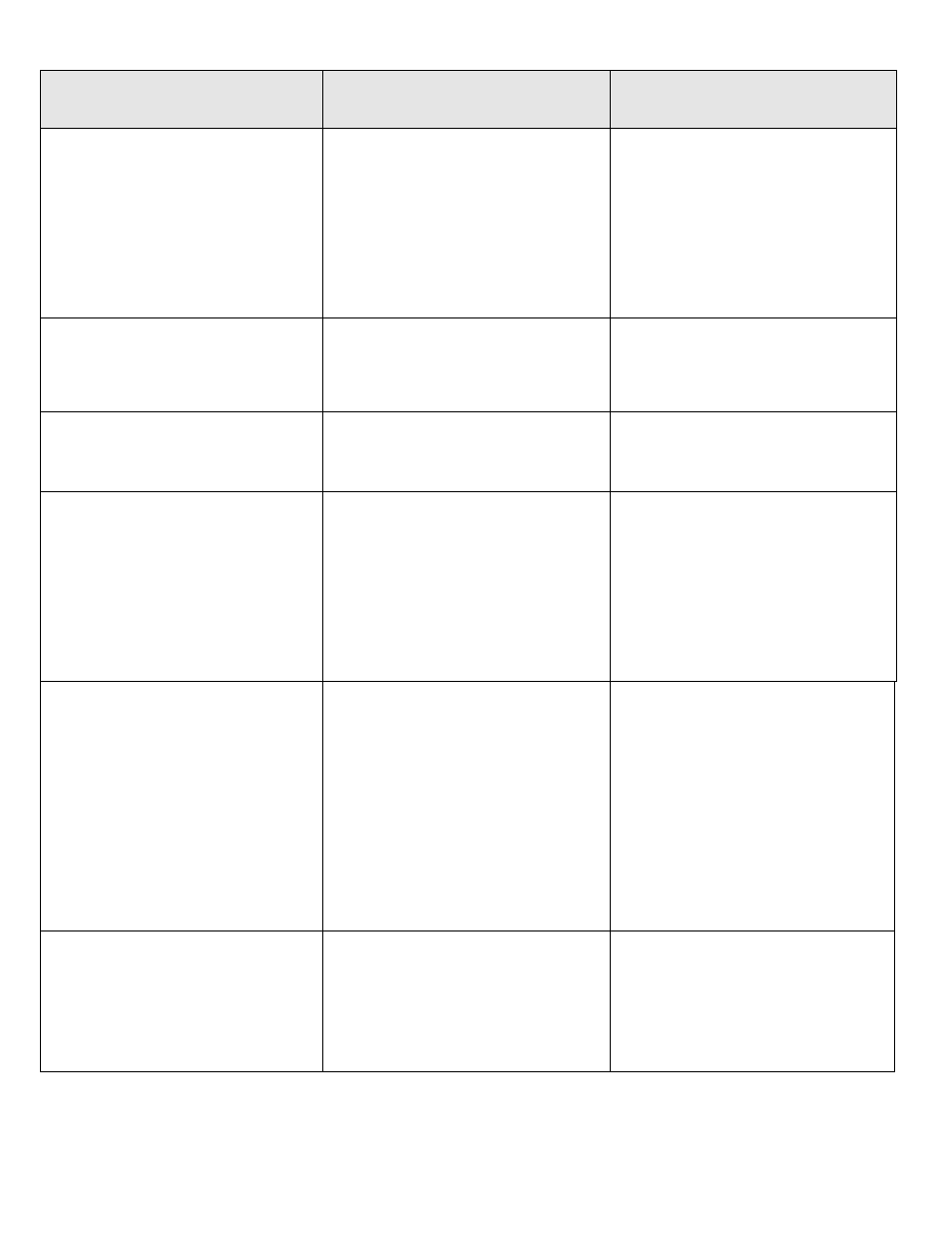

Problem

Probable Cause

Solution

Compressor relief valve activates

(popping sound)

•

Faulty electrical connection at waste

valve.

•

Faulty solenoid valve coil.

•

(Acceptable rating: 713-837 Ohms)

•

Contaminated sieve beds.

•

Faulty circuit board.

•

Faulty relief valve.

•

Repair electrical connection.

•

Replace valve coil. (Use of an

ohmmeter can be helpful to easily

determine faulty coil).

•

Replace sieve beds.

•

Replace circuit board.

•

Replace relief valve.

Unit alarms with

l/0

power switch

in “

I

” position. Circuit breaker

repeatedly trips.

•

Faulty electrical connection.

•

Faulty capacitor.

•

Faulty circuit breaker.

•

Faulty compressor.

•

Faulty circuit board.

•

Repair electrical connection.

•

Replace capacitor.

•

Replace circuit breaker.

•

Replace compressor.

•

Replace circuit board.

Cabinet fan does not turn.

•

Faulty electrical connections.

•

Faulty cabinet fan.

•

Check electrical connections.

•

Replace cabinet fan.

Flowmeter fluctuates

•

Improperly set or faulty product

regulator.

•

Leak.

•

Reduced air intake (suction)

•

Faulty flowmeter.

•

Worn compressor.

•

Faulty circuit board.

•

Faulty solenoid valve.

•

Check regulator setting. Repair or

replace regulator.

•

Leak test and repair leak.

•

Check compressor intake path for

obstruction. Remove obstruction.

•

Replace flowmeter.

•

Replace compressor

•

Replace circuit board.

•

Replace solenoid valve manifold.

Limited or low flow.

•

Restriction in humidifier/tubing.

•

Product regulator set too low.

•

Leak.

•

Reduced air intake (suction)

•

Weak compressor

•

Faulty circuit board

•

Restriction in mixing tank

•

Faulty solenoid valve.

•

Replace humidifier or tubing.

•

Adjust regulator setting.

•

Leak test and repair.

•

Check compressor intake path for

obstruction and remove, if needed.

•

Check system pressure, and rebuild or

exchange compressor.

•

Replace circuit board.

•

Replace mixing tank

•

Replace valve manifold.

No flow indicated on flow meter,

and 6-beep no flow alarm does

not activate.

•

Internal leak. (likely in location from

unit regulator to flow meter)

•

Main circuit boards prior to Rev. R do

not have a ‘no flow’ alarm

•

Leak test and repair. In particular,

regulator / fittings following air path

to flow meter. Repair leaks.