Dwyer GFC User Manual

Page 15

5.4 Setpoint Reference Signal

GFC flow controllers have a built-in solenoid valve (GFC-110/111/113/114) or

motorized valve (GFC-1143/1144/1145) and allow the user to set the flow to any

desired flow rate within the range of the particular model installed. The solenoid

valve is normally closed when no power is applied.

The motorized valve can be in any position depending on the operation mode of

the GFC during disconnecting of the power. For example if the motorized valve

was left in the OPEN purge position after disconnecting power from the GFC it will

be in the OPEN position. It is the customers responsibility to provide a solution to

shut down the flow in case of a power outage. When power is applied for the

GFC-1143/1144/1145 the valve automatically closes within the first ten seconds

regardless of the set point and valve override signals.

The setpoint is controlled either locally or remotely. The setpoint input responds to

an analog 0 to 5 VDC or 4 to 20 mA reference voltage (default jumper setting is 0

to 5 VDC). This voltage is a linear representation of 0 to 100% of the full scale

mass flow rate. Response time to setpoint changes are 1 second (GFC17), 2 sec-

onds (GFC37/47) and 5 seconds (GFC-1143/1144/1145) within 2% of the final

flow over 25 to 100% of full scale.

For LOCAL flow control, use the built-in setpoint potentiometer located on the

same side as the solenoid valve of the GFC transducer. While applying flow to

the transducer, adjust the setpoint with an insulated screwdriver until the flow

reading is the same as the desired control point. [The display will only show the

actual instantaneous flow rate. There is no separate display for setpoint.]

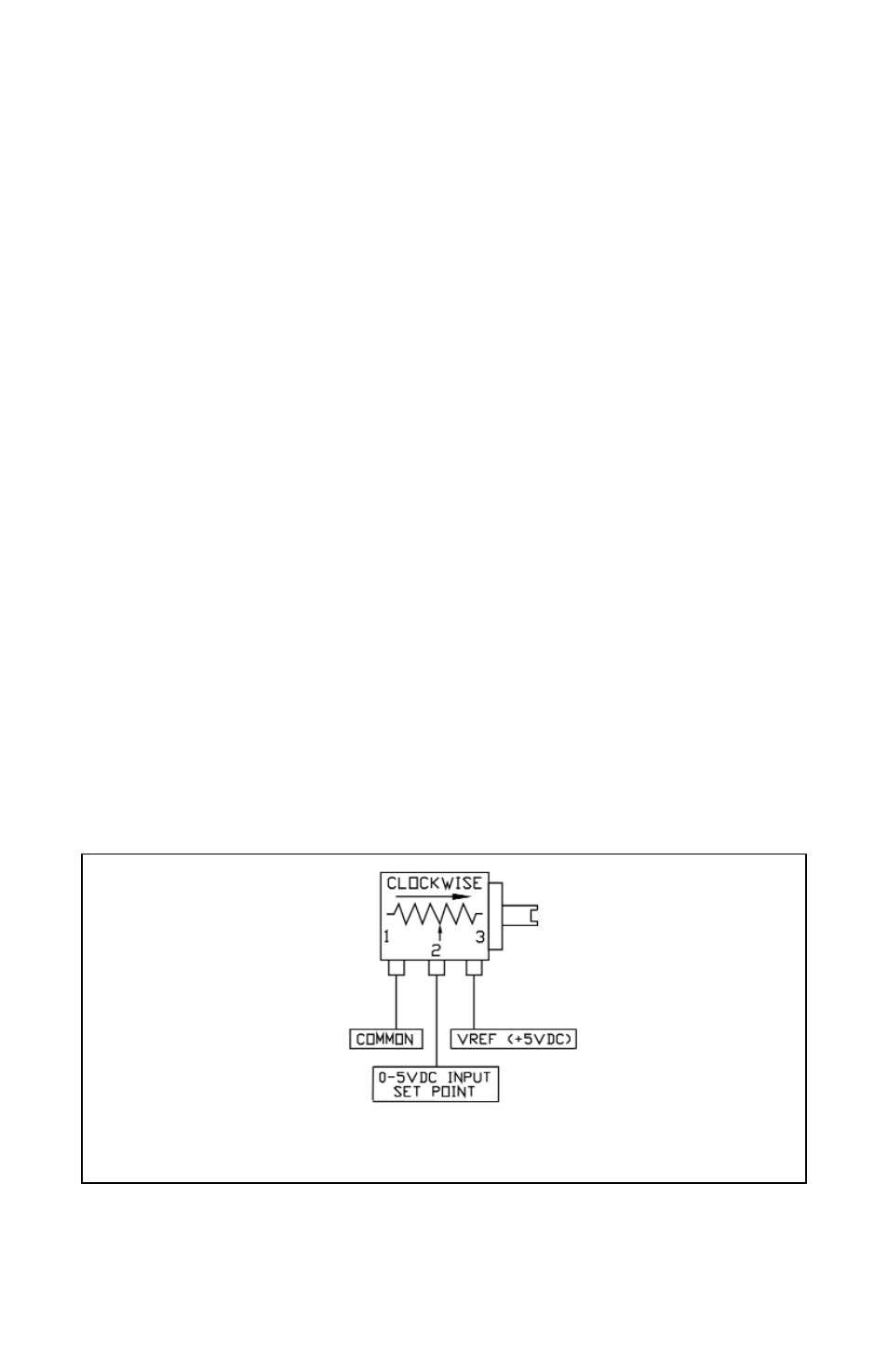

For REMOTE control of the GFC, an analog reference signal must be supplied.

On pin 11 of the GFC transducer is a regulated and constant +5VDC output sig-

nal. This signal may be used in conjunction with a local setpoint potentiometer for

flow setting.

FIGURE 5-A LOCAL SETPOINT POTENTIOMETER CONNECTIONS

It is recommended that a potentiometer between 5K to 100K ohm and capable of

at least 10-turns or more for adjustment be used. Use the control potentiometer

to command the percentage of flow desired.

11