Caleffi 678 User Manual

Page 2

Installazione

Installation

Einbau

Installation

Instalación

Instalação

Installatie

Установка

Materials: - protective cap

self-extinguishing polycarbonate

- colour

white RAL 9010 (code 656102/04 - 656302/04)

grey RAL 9002 (code 656112/14 - 656312/14)

Normally closed

Supply:

230 V

(ac)

- 24 V

(ac)

- 24 V

(dc)

Starting current:

≤ 1 A

Working current:

230 V

(ac)

= 13 mA

24 V

(ac)

- 24 V

(dc)

= 140 mA

Power consumption:

3 W

Rating of micro switch (code 656112/14 - 656312/14):

0,8 A (230 V)

Protection class:

- 6651

IP 44 (in vertical position)

- 6653

IP 40 (in vertical position)

Product with double insulation:

CE

Max. ambient temperature:

50°C

Operating time:

opening and closing from 120 s to 180 s

Supply cable length:

80 cm

- Nel montaggio delle valvole sull’impianto rispettare il senso di

flusso delle frecce incise sul corpo.

- La valvola a due vie può essere installata sia sulla tubazione di

andata che su quella di ritorno.

- La valvola a tre o quattro vie va installata sulla tubazione di

mandata.

- La valvola va installata con manopola rivolta verso l’alto o in

posizione orizzontale, mai in posizione rovesciata.

- Nell’installazione in cassetta lasciare uno spazio di almeno 20 mm

tra comando elettrotermico e telaio per un eventuale sostituzione

o manutenzione.

- La valvola a tre vie non può essere trasformata in valvola a due vie.

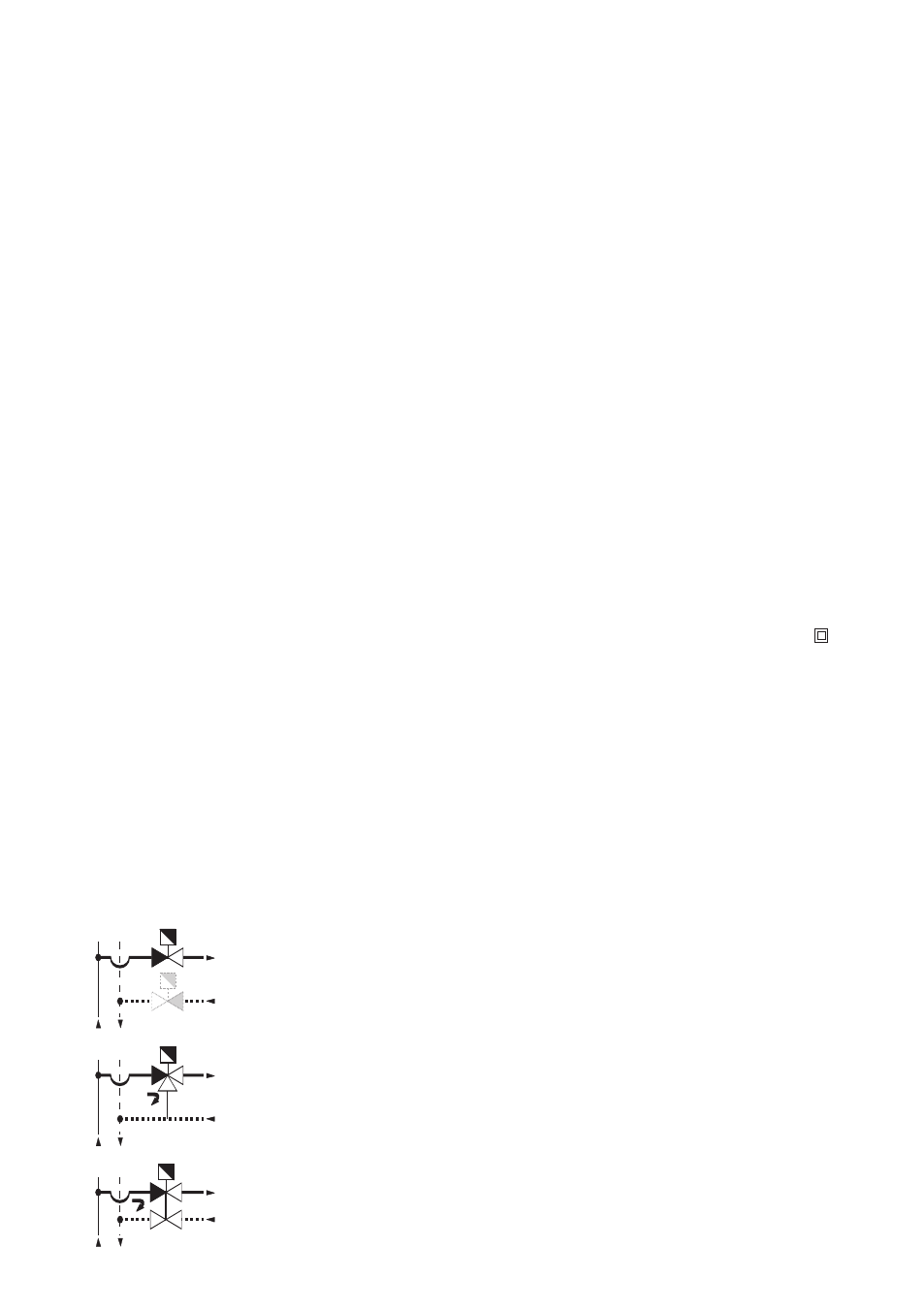

- When mounting the valve onto the system the arrows indicating the

flow direction must be respected.

- The two-way valve can be installed either on the supply pipe or on

the return pipe.

- The three or four-way valve should be installed on the supply pipe.

- The valve should always be installed with the handle in the up-

right or horizontal position, it should never be in the upside-down

position.

- When the valves are installed into boxes, there must be at least

20 mm of space left between the control actuator and the frame.

This is for maintenance or replacement reasons.

- The 3-way valve should never be converted into a 2-way valve.

Actuator technical

specification

Materials: - body:

brass EN 12165 CW617N

- obturator:

brass EN 12165 CW617N

- control spindle:

stainless steel

- hydraulic seals:

EPDM

- Medium:

water, glycol solutions

- Max. percentage of glycol:

30%

- Temperature range:

0÷95°C

- Max. pressure:

10 bar

- Max. pressure differential:

1,2 bar

- Connections:

1/2”, 3/4”, 1”, M with union

- Bottom 3-way connection:

1/2” M with union

- Kv:

3,7 m

3

/h

- Kv by-pass:

1 m

3

/h

Valve technical

specification

Hydraulic

characteristics

2