Vii. troubleshooting – Badger Meter Turbine Flow Meters (Hydraulic Fluids) User Manual

Page 15

Turbine Flow Sensor

Installation & Operating Instructions

03/12 Form No. 05-TUR-UM-00194

Page 15

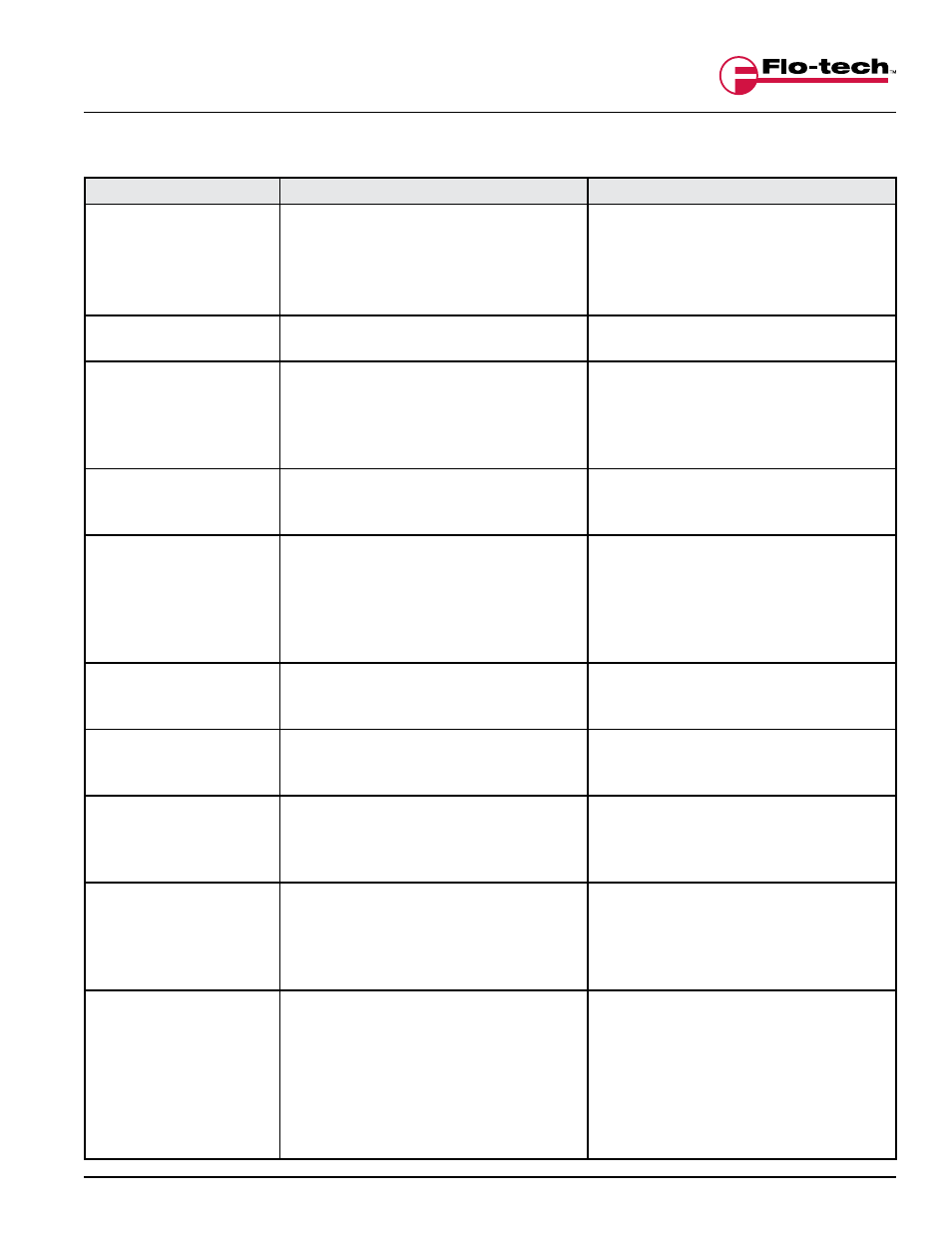

VII. TROUBLESHOOTING

TROUBLE

POSSIBLE CAUSE

REMEDY

Sensor indicates higher

than actual flow rate

• Cavitation

• Debris on straightening section

• Build-up of foreign material on sensor

bore

• Gas in liquid

• Increase back pressure

• Clean sensor

• Clean sensor

• Install gas eliminator ahead of sensor

Sensor indicates lower

than actual flow rate

• Debris on turbine

• Worn bearing

• Clean sensor and add filter

• Have sensor serviced and add filter

Erratic indications on

readout

• Any of the above

• Ground loop problem

• Turbulence in fluid stream

• Any of the above

• Be sure only one system ground is

present. Reroute cables away from

electrical noise

• Redo plumbing per instructions

Readout shows flow

when pumps are not

running

• Mechanical vibration or pump dither

causes turbine to oscillate even though

there is no flow

• Isolate flow sensor

No flow indication at any

flow rate

• Foreign material stopping turbine

rotation

• Damaged turbine and/or bearing

• Magnetic pick-up stopping turbine

rotation

• Magnetic pick-up shorted or open

• Clean sensor and add filter

• Have sensor serviced

• Readjust magnetic pick-up away from

turbine

• Have magnetic pick-up replaced

Erratic indications at

low flows, but good

indications at high flows

• Foreign material wrapped around

turbine

• Clean sensor and add filter

System works except

readings are lower than

expected

• Flow is being bypassed

• System has a leak

• Repair or replace faulty valves

• Find and repair any system leaks

No current output

• Low or missing supply voltage

• Broken / disconnected wires

• Incorrect wiring polarity

• Check polarity of the current loop

connections for proper orientation

• Make sure receiving device is

configured to provide loop current

Analog output reads a

constant reading all the

time

• Electrical noise in vicinity

• Damaged electronics

• Make sure there is flow in the system

• Verify that the rotor inside the turbine

meter turns freely

• Check shield

• Remove noise producing device

Analog output is not

stable

• Electrical noise in vicinity

• Entrained gas in liquid

• Damaged meter rotor

• Foreign matter lodged in turbine

• External noise is being picked up by

the sensor. Keep all AC wires separate

from DC wires.

• Check for radio antenna in close

proximity. This usually indicates a weak

signal.

• Clean meter

• Recalibrate meter