Figure 3, Figure 4 – Badger Meter 3-A Sanitary User Manual

Page 8

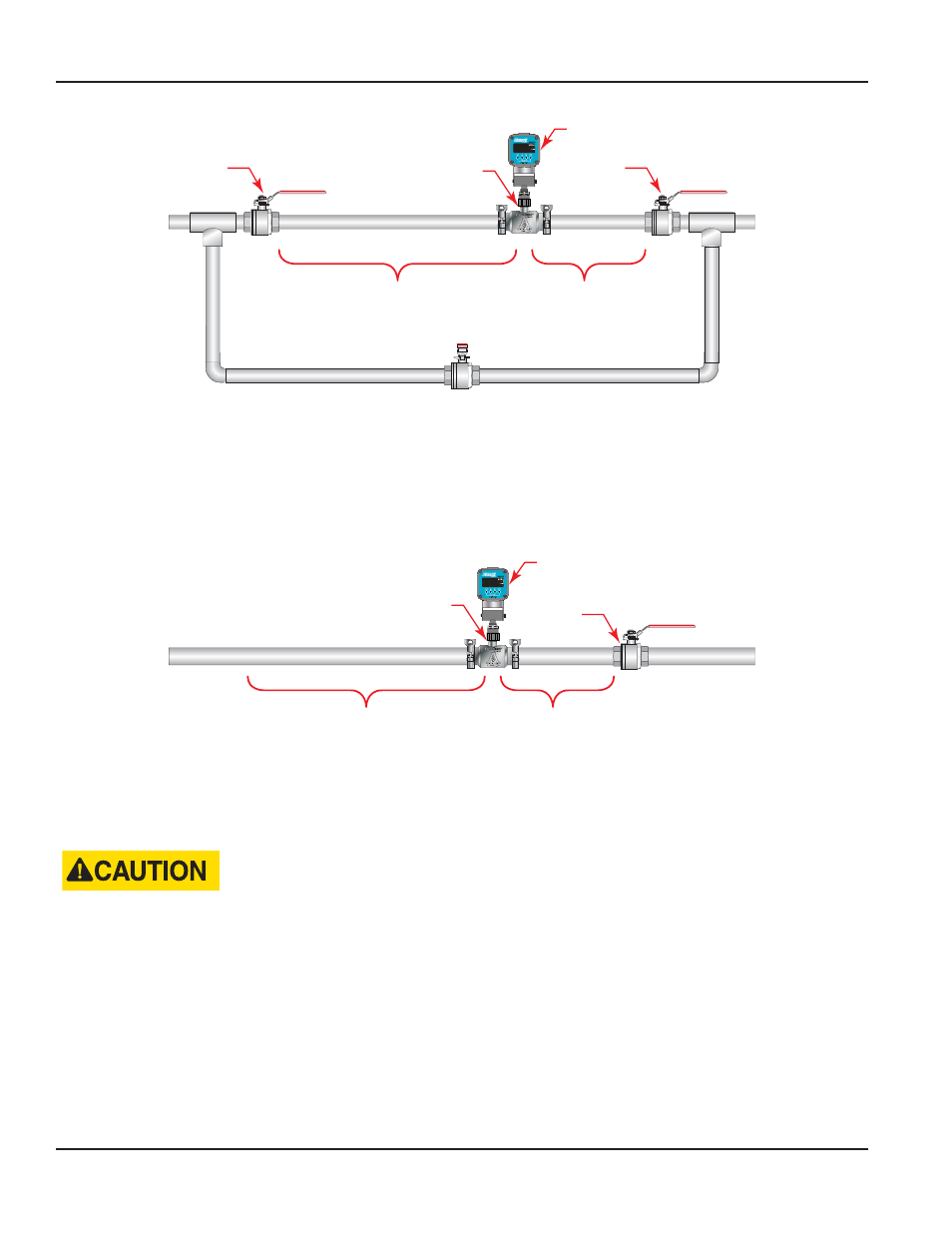

Bypass Line

5 Pipe Diameters

Minimum

10 Pipe Diameters

Minimum

Isolation

Valve

Display

FloClean Turbine

Flow Meter

Isolation

Valve

2

1

Figure 3: Installation with bypass line

This is true with any restriction in the flow line that may cause the liquid to flash If necessary, air eliminators should be

installed to ensure that the meter is not incorrectly measuring entrained air or gas

It is recommended that a minimum length, equal to ten (10) pipe diameters of straight pipe, be installed on the upstream side

and five (5) diameters on the downstream side of the flow meter Otherwise, meter accuracy may be affected Piping should

be the same size as the meter bore or threaded port size

5 Pipe Diameters

Minimum

10 Pipe Diameters

Minimum

FloClean Turbine

Flow Meter

Isolation

Valve

Display

2

1

Figure 4: Installation without a bypass line

Do not locate the flow meter or connection cable close to electric motors, transformers, sparking devices, high voltage lines,

or place connecting cable in conduit with wires furnishing power for such devices These devices can induce false signals in

the flow meter coil or cable causing the meter to read inaccurately

DAMAGE CAN BE CAUSED BY STRIKING AN EMPTY METER WITH A HIGH VELOCITY FLOW STREAM.

If problems arise with the flow meter and monitor, consult the

TROUBLESHOOTING GUIDE on page 16

If further problems

arise, consult the factory

If the internal components of the turbine flow meter are damaged, turbine meter repair kits are available Information

pertaining to the turbine meter repair kits is referenced in

Turbine Flow Meter, FloClean Sanitary Flow Meter

Page 8

November 2013