Troubleshooting guide, Troubleshooting guide 16 – Badger Meter 3-A Sanitary User Manual

Page 16

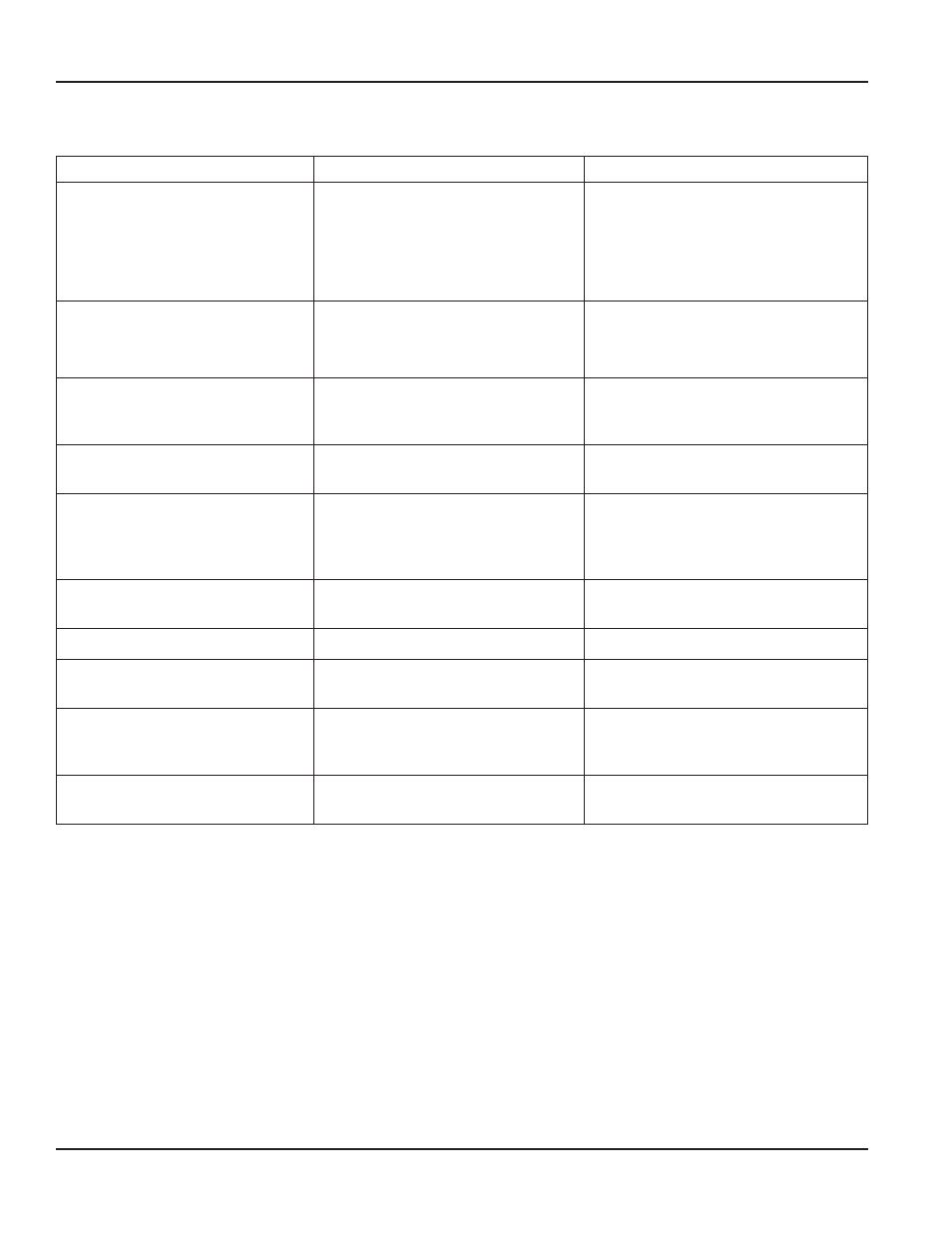

TROUBLESHOOTING GUIDE

Trouble

Possible Cause

Remedy

Meter indicates higher than actual

flow rate

• Cavitation

• Debris on rotor support

• Build up of foreign material on

meter bore

• Gas in liquid

• Increase back pressure

• Clean meter

• Clean meter

• Install gas eliminator ahead of meter

Meter indicates lower than actual

flow rate

• Debris on rotor

• Worn bearing

• Viscosity higher than calibrated

• Clean meter and add filter

• Install new repair kit

• Recalibrate monitor

Erratic system indication, meter

alone works well (remote monitor

application only)

Ground loop in shielding

Ground shield one place only Look for

internal electronic instrument ground

Reroute cables away from electrical noise

Indicator shows flow when shut off

Mechanical vibration causes rotor to

oscillate without turning

Isolate meter

No flow indication, full or partial

open position

Fluid shock, full flow into dry meter or

impact caused bearing separation or

broken rotor shaft

Rebuild meter with repair kit and

recalibrate monitor Move to location

where meter is full on startup or add

downstream flow control valve

Erratic indication at low flow, good

indication at high flow

Rotor has foreign material wrapped

around it

Clean meter and add filter

No flow indication

Faulty pickup

Replace pickup

System works perfect, except

indicates lower flow over entire range Bypass flow, leak

Repair or replace bypass valves or faulty

solenoid valves

Meter indicating high flow, upstream

piping at meter smaller than meter

bore

Fluid jet impingement on rotor

Change piping

Opposite effects of above

Viscosity lower than calibrated

Change temperature, change fluid or

recalibrate meter

Turbine Flow Meter, FloClean Sanitary Flow Meter

Page 16

November 2013