Introduction, Theory of operation, Specifications – Badger Meter 3-A Sanitary User Manual

Page 5: Introduction 5, Theory of operation 5, Specifications 5

INTRODUCTION

The Blancett FloClean turbine flow meter is designed with wear resistant moving parts to provide trouble-free operation and

long service life The durable 316L stainless steel construction provides a cost efficient flow measurement system that offers

excellent accuracy and repeatability The FloClean turbine meter repair kit is designed for easy field service of a damaged flow

meter, rather than replacing the entire flow meter See

for information

THEORY OF OPERATION

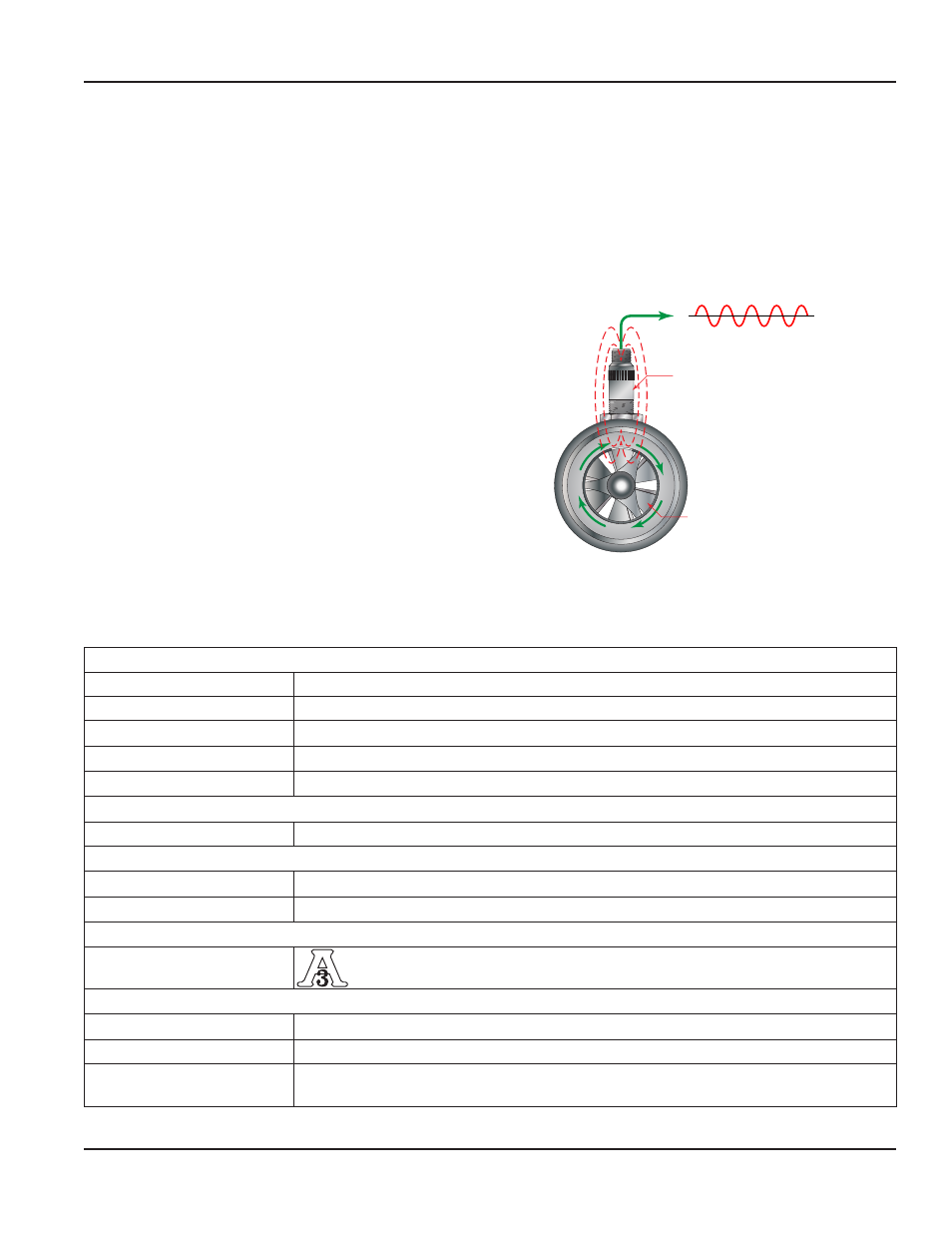

Fluid entering the meter passes through the inlet flow straightener

which reduces its turbulent flow pattern and improves the fluid’s

velocity profile Fluid then passes through the turbine, causing it to

rotate at a speed proportional to the fluid velocity As each turbine

blade passes through the magnetic field, the blade generates an

AC voltage pulse in the pickup coil at the base of the magnetic

pickup (see

) These pulses produce an output frequency

proportional to the volumetric flow through the meter The output

frequency represents flow rate and/or totalization of fluid passing

through the turbine flow meter

Rotor

Magnetic

Pickup

Output Signal

Figure 1: Theory of operation

SPECIFICATIONS

Physical

Body/Internal Wetted Parts

316L stainless steel

Bearings

Nickel bindery tungsten carbide

Turbine

Nickel plated CD4MCU stainless steel

Shaft

Nickel bindery tungsten carbide

Connections

Sanitary clamp ends

Electrical

Pickup (option 0)

NEMA 6; –150…300° F (–100…149° C)

Accuracy

Accuracy

±1% of reading

Repeatability

±0 1%

Certifications

Construction

Temperature

–150…300° F (–101…149° C)

Pressure Rating

1000 psi maximum (rating based on Tri-Clamp sanitary connection)

Corrosion

Contact Blancett to determine if operating liquid is compatible with

materials of construction

User Manual

Page 5

November 2013