Badger Meter M-Series M3000 User Manual

Page 7

7

METER/AMPLIFIER LOCATION, ORIENTATION and

APPLICATIONS

Remote Amplifi er Outdoor Location

The amplifi er can be installed and operated outdoors.

However, protection from the elements must be considered:

1. Be aware of the ambient environment and

temperature ratings for the unit -4°F to 122°F (-20°C to

50°C).

2. If an indoor location is within 100 feet (30m) of the

detector installation, consider increasing the cable length

and mounting the amplifi er indoors.

3. At a minimum, fabricate a roof or shield over and/or

around the amplifi er to protect the LCD display screen

from sunlight.

Temperature

To prevent meter damage in any environment, minimum and

maximum temperature ranges must be observed.

1. For remote amplifi er applications, the fl uid temperature

range is -4°F to 248°F (-20°C to 120°C) at a maximum

ambient temperature of 122°F (50°C) for the following

liner materials: PFA, PTFE and Halar

®

.

2. For remote amplifi er applications, the fl uid temperature

range is 32°F to 178°F (0°C to 80°C) at a maximum

ambient temperature of 122°F (50°C) for the following

liner materials: Hard rubber and soft rubber.

3. For meter mounted amplifi er applications, the fl uid

temperature range is -4°F to 212° (-20°C to 100°C) at a

maximum ambient temperature of 122°F (50°C) for the

following liner materials: PFA, PTFE and Halar.

4. For meter mounted amplifi er applications, the fl uid

temperature range is 32°F to 178°F (0°C to 80°C) at a

maximum ambient temperature of 122°F (50°C) for the

following liner materials: Hard rubber and soft rubber.

5. The ambient temperature range surrounding the amplifi er

is -4°F to 122°F (-20°C to 50°C.)

6. The ambient temperature range surrounding a remote

junction box mounted to the detector is -4°F to 248°F

(-20°C to 120°C.)

Pipelines and Fluid Flow

Pipeline and fl uid fl ow conditions that should be avoided:

1. Do not install the meter where extreme pipe vibrations

exist. If vibrations are present, secure piping before

and after the meter with appropriate pipe supports. If

vibrations can’t be restrained, consider mounting the

amplifi er remotely.

2. Avoid installing the detector close to pipeline valves,

fi ttings or impediments that can cause fl ow disturbances.

3. For detectors with PTFE liners, avoid installing the

detector on suction sides of pumps.

4. Avoid installing the detector on outlet sides of piston

or diaphragm pumps. Pulsating fl ow can affect meter

performance.

5. Avoid locations near equipment producing electrical

interference such as electric motors, transformers, variable

frequency, power cables, etc.

6. Verify both ends of the signal cables are securely

fastened.

7. Place power and signal cables in separate conduit.

8. Place the meter where there is enough access for

installation/maintenance purposes.

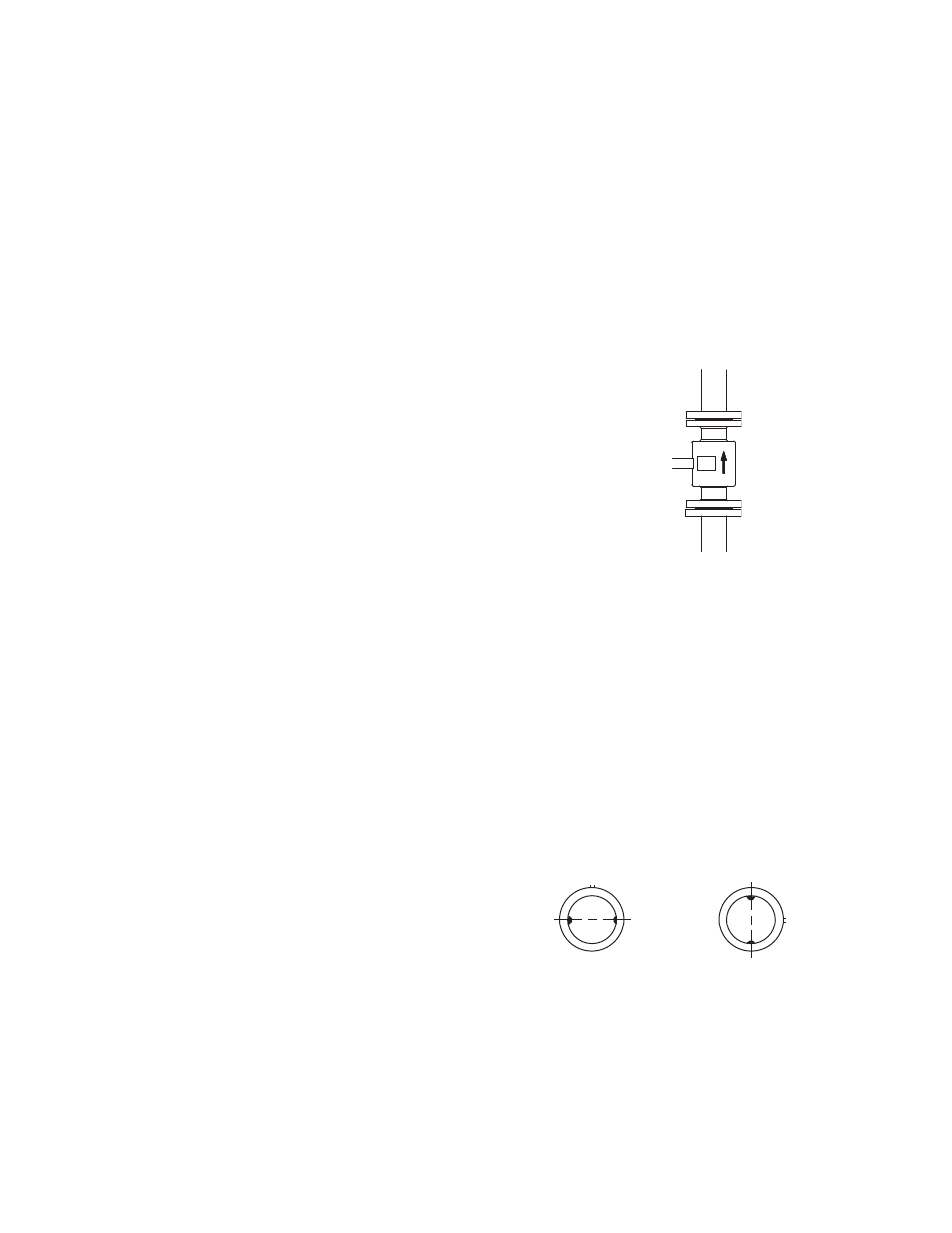

Meter Orientation

Mag meters can operate accurately in any pipeline

orientation and can measure volumetric fl ow in forward and

reverse directions.

NOTE: A Forward Flow direction arrow is printed on the

detector label.

Vertical Placement

Mag meters attain optimal performance when placed

vertically, with liquid fl owing upward and meter electrodes in

a closed, full pipe.

Vertical placement allows the pipe to remain completely full,

even in low fl ow, low pressure applications and it prevents

any solids build-up or sediment deposit or accumulation on

the liner and/or electrodes.

NOTE: Carefully observe the “Forward Flow” label on the

meter body and install the meter accordingly.

Horizontal Placement

In a horizontal piping orientation, mount the detector to

piping with the fl ow measuring electrode axis in a horizontal

plane (3 and 9 o’clock).

This arrangement prevents solids build-up or sediment

deposit or accumulation on the electrodes.

Electrode

Plane

RIGHT

Electrode

Plane

WRONG