Meter orientation, Vertical placement, Horizontal placement – Badger Meter M-Series M5000 User Manual

Page 9: Straight pipe requirements, Meter location, orientation and applications

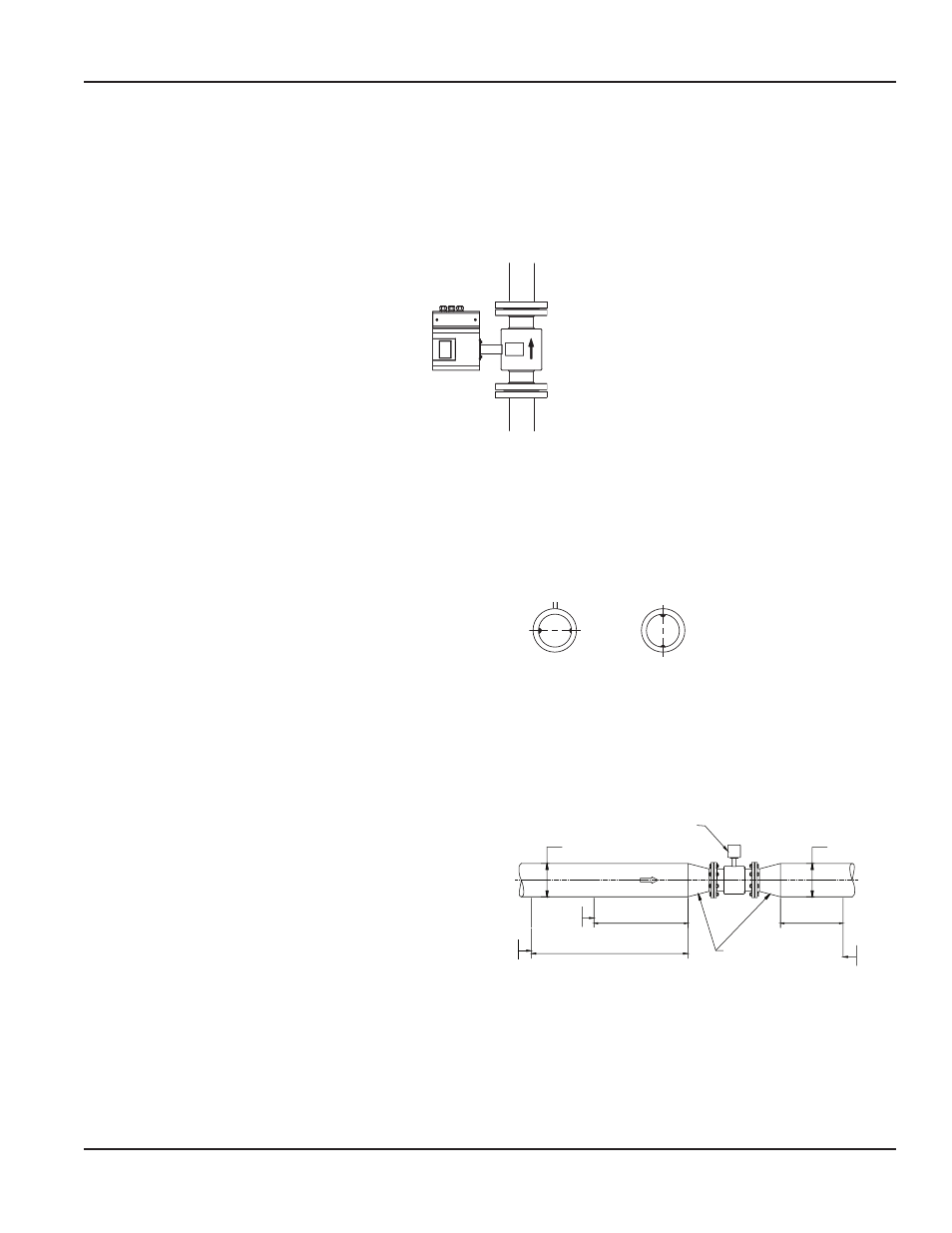

Meter Orientation

Mag meters can operate accurately in any pipeline orientation and can measure volumetric flow in forward and reverse

directions .

OTEE:

N

A "Forward Flow" direction arrow is printed on the detector label .

Vertical Placement

Mag meters perform best when placed vertically, with liquid flowing upward and meter electrodes in a closed, full pipe .

Figure 6: Vertical Placement

Vertical placement allows the pipe to remain completely full, even in low flow, low pressure applications, and it prevents

solids build-up, sediment deposit and accumulation on the liner and electrodes .

OTEE:

N

Carefully observe the “Forward Flow” label on the meter body and install the meter accordingly . When installed

vertically, rotate amplifier so that cable glands are facing down .

Horizontal Placement

M5000 meters are equipped with an Empty Pipe

Detection feature . If an electrode mounted in the pipe

is not covered by fluid for five seconds, the meter will

display an Empty Pipe Detection condition . The meter

will send out an error message and stop measuring

flow . When the electrode is again covered with fluid,

the error message disappears and the meter will begin

measuring .

Electrode

Plane

RIGHT

Electrode

Plane

WRONG

Figure 7: Horizontal Placement

When installing the meter on a horizontal pipe, mount the detector to the pipe with the flow-measuring electrode axis in a

horizontal plane (three and nine o’clock) . This placement helps prevent solids build-up, sediment deposit and accumulation

on the electrodes .

Straight Pipe Requirements

Sufficient straight-pipe runs are required at the

detector inlet and outlet for optimum meter accuracy

and performance . An equivalent of three diameters of

straight pipe is required on the inlet (upstream) side . Two

diameters are required on the outlet (downstream) side .

FORWARD FLOW

MINIMUM STRAIGHT PIPE

MINIMUM STRAIGHT PIPE

ELBOW

TEE

GATE VALVE

(FULLY OPEN)

MINIMUM STRAIGHT PIPE

CHECK VALVE

GLOBE VALVE

BUTTERFLY VALVE

PUMP

ELBOW

TEE

ANY VALVE

FLOWMETER

3 x D

7 x D

2 x D

D (Pipe Size)

D (Pipe Size)

MINIMUM PIPING REQUIREMENT

STANDARD CONCENTRIC

REDUCERS

(NO DISTANCE REQUIRED)

Figure 8: Straight Pipe Requirements

Meter location, orientation and applications

MAG-UM-00219-EN-03

Page 9

August 2014