KROHNE BM 102 EN User Manual

Page 7

BM

102

7

1.2 Installation

restrictions

Hazardous-duty systems (Ex, FM,…)

• Refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and

Operating Instructions supplementary instructions for further information on installing gauges

approved for use in hazardous locations. This document is available from your local KROHNE

Sales office or on the “Download Centre” on KROHNE’s website http://www.krohne.com/.

• Check that the flange, gasket and probe materials are compatible with the product. Read the

information given on the converter nameplate, the flange markings and specifications in the

approval certificates.

1.3

Mounting on the tank

1.3.1 Installation Instructions: General notes

The fitter should give some thought to tank fittings and tank shape.

• Nozzle position in relation to the tank walls and other objects inside the tanks

(Warning : this free area will depend on the probe type selected: refer to later on in this section)

• Type of tank roof , i.e. floating, concrete, integral, etc; and base, i.e. conical, etc.

Whenever working on an installation, remember to:

• Disconnect the power supply before starting work.

• Drain the tank completely before installing the device (not applicable to cable probes).

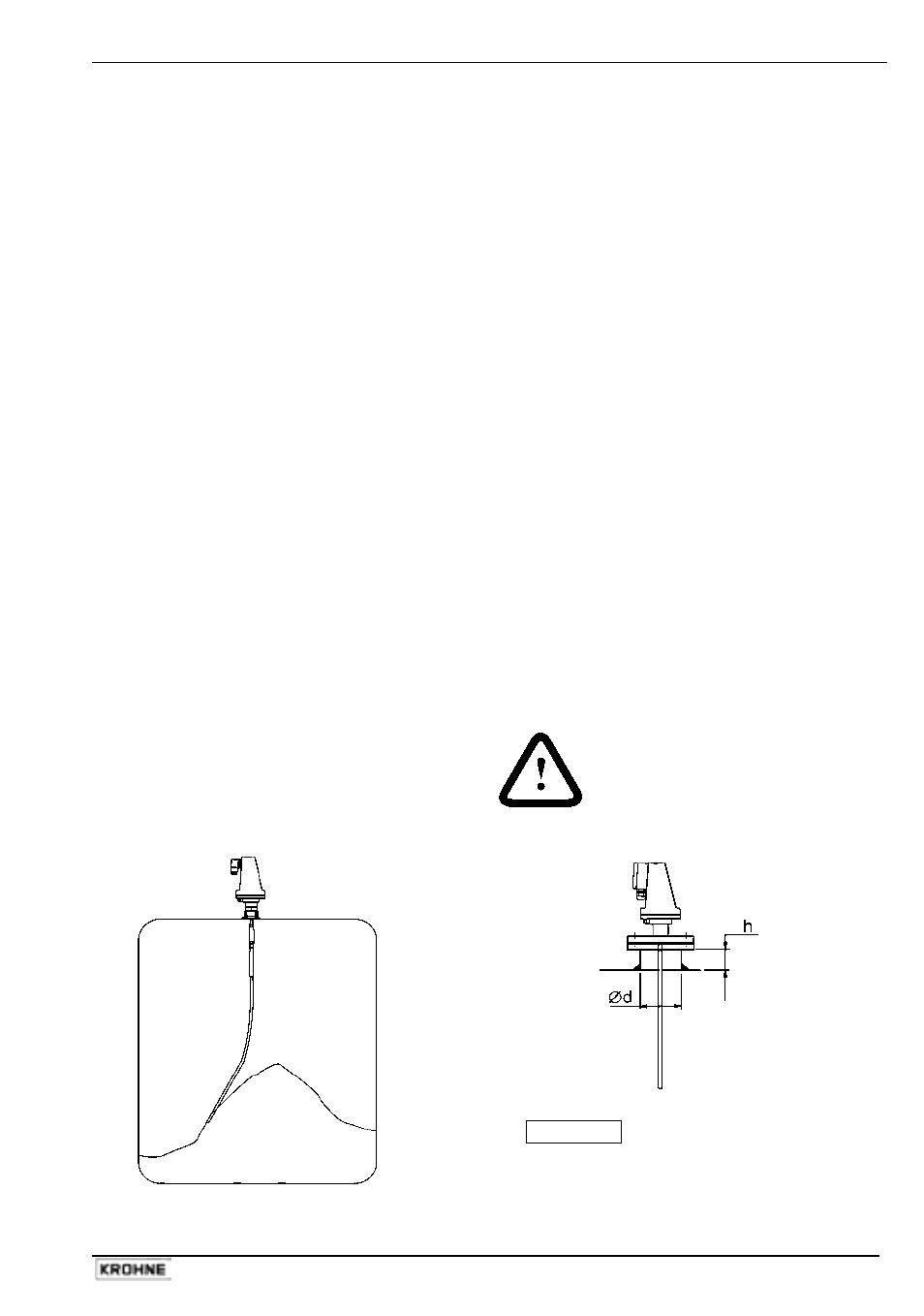

1.3.2 Installation instructions: nozzle

Threaded process connections

Nozzle height

Recommendation

The simplest and most economic way is to

mount the BM 102 directly on the tank with a

GAS or NPT threaded connection.

Do not fit a nozzle longer than its

diameter , especially for single

probes and powder applications

h ≤ Ød

, where h = nozzle height and

d = nozzle diameter

Contact KROHNE if this relationship cannot be

respected.