KROHNE BM 102 EN User Manual

Page 3

BM

102

3

Device description and range of applications

The BM 102 MICROFLEX level gauge uses the Time Domain Reflectometry (TDR) measuring

principle and two-wire technology for level measurement. It is designed solely for measuring the

distance, level, volume and ullage of liquids, pastes, slurries and powders. It can continue to

measure the level or distance of the top product and total volume in applications with two or more

products.

The level measurement data can be displayed and the gauge configured using either a HART

Handheld Communicator console (HHC) or a PC work station equipped with PCSTAR 2 software

which is supplied as standard with the gauge.

Principal gauge components

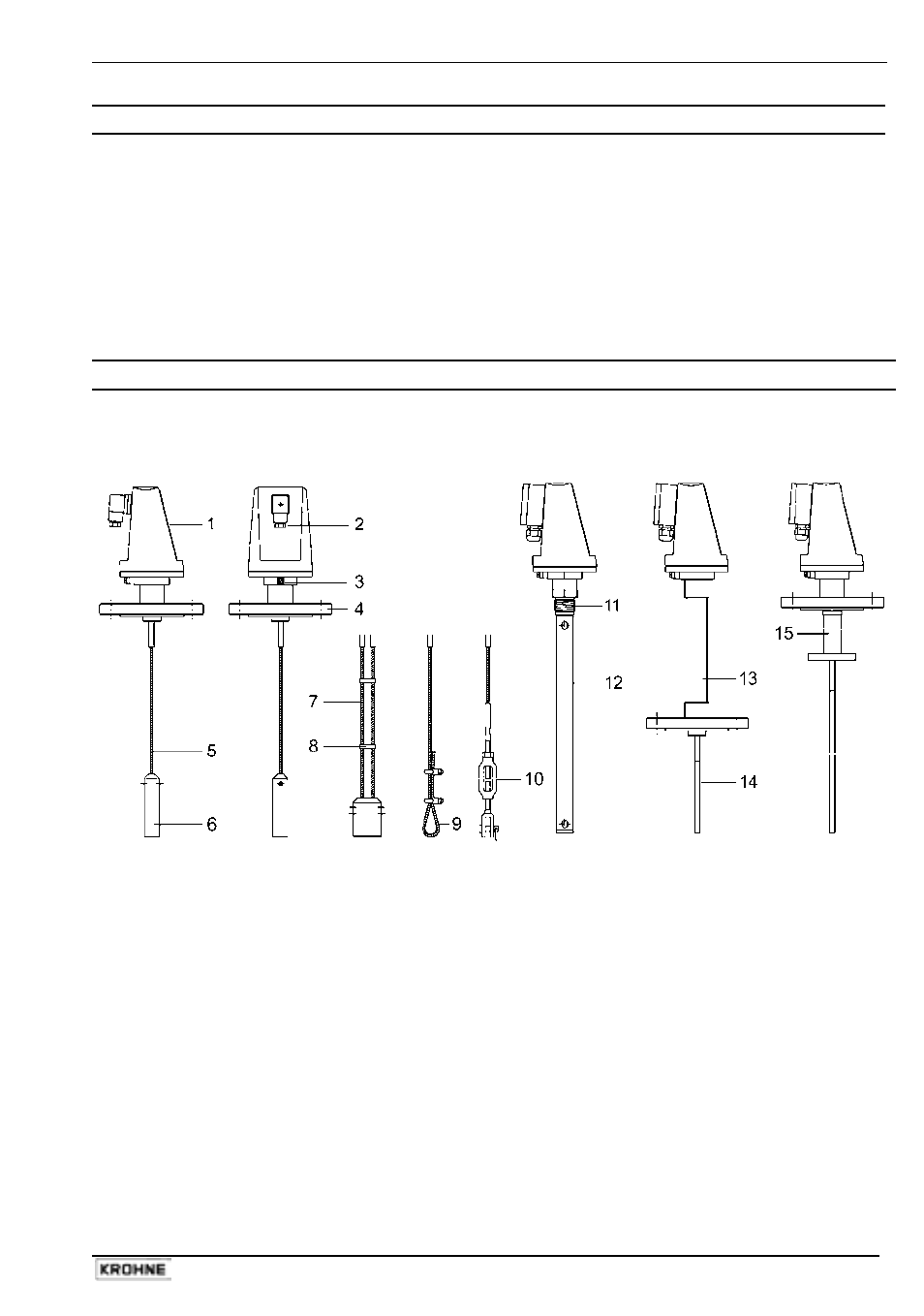

BM 102 housing and probes (non-Ex and Ex versions)

with high-

temperature

option

with raising

converter

option

1

Nameplate (see next page for details)

2

Cable entry (output and power supply) to wiring compartment

3

Equi-potential bonding system connection (for Ex applications)

4

Flange (process connection onto tank or other suitable mounting)

5

Single cable probe

6

Counterweight (with threaded hole in base for anchoring)

7

Twin cable probe

8 Spacer

9

Chuck (for single cable probes)

10

Turnbuckle (for twin or single cable probes)

11

Threaded process connection (e.g. G1, NPT1, …)

12 Coaxial

probe

13

Extension tube for high temperature applications

14 Single

rod

probe

15

Raising converter: coaxial tube under the process connection (i.e. an inactive length of

the probe) for installations with long nozzles or concrete roofs – for single rod and single

cable probe versions only