3 magcheck as manual flow signal calibrator – KROHNE MAGCHECK EN User Manual

Page 14

14

MagCheck

3.2.2 Explanation of the automatic verification run (verified data)

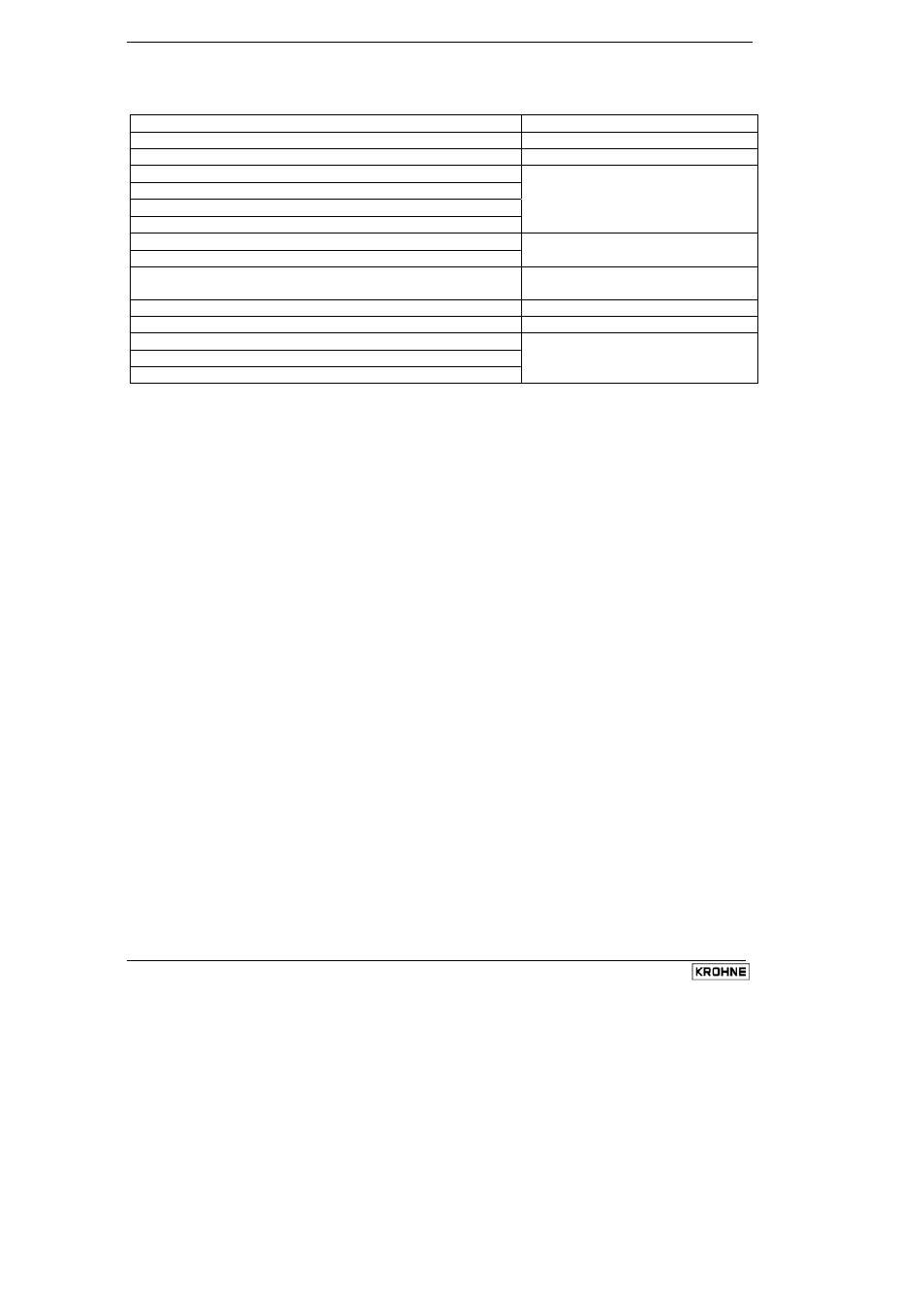

Converter data

Data indicated and stored

Measurement of the field current

Calibrated and actual value [mA]

Measurement of field frequency

Act frequency [Hz]

ADC linearity and accuracy test at 25% of full scale

1)

ADC linearity and accuracy test at 50% of full scale

1)

ADC linearity and accuracy test at 75% of full scale

1)

ADC linearity and accuracy test at 100 % of full scale

1)

Output of input amplifier and

analogue to digital converter: True

and act. value [% of full scale]

Testing of the 1st calibration point P04 for current output

2)

Testing of the 2nd calibration point P20 for current output

2)

Calibrated and actual value [mA]

Testing of the 1st pulse output with f = 500 Hz

3)

True and actual value [Hz] for

f100% = 1000Hz

If flowhead is tested as well

Measurement of field coil resistance

Coil resistance (Ohms)

Measurement of resistance of electrode 1

4)

Measurement of resistance of electrode 2

4)

Measurement of isolation resistance of field coils

Resistance values are measured.

Display of subsequent voltage

levels and resistance values

Following the measurement, the measured data are stored in the MagCheck.

1) ADC test verifies accuracy of input amplifier and analogue to digital conversion of flow signal

During this test the GK of the converter is temporarily set to factory test conditions GK = 2.500.

At end of verification the GK will be reprogrammed automatically by MagCheck to original data.

2) mA output tests verify compliance of mA output with factory calibration settings

Time constant T settings via IMoCom is reduced by MagCheck to allow for sufficiently fast

settling of mA output and pulse output. At the end of the verification, the time constant will be

reprogrammed automatically by MagCheck to original data.

3) For test of frequency / pulse output setting of this output will be temporarily programmed by

MagCheck to 1000 Hz at full scale flow. At end of verification frequency / pulse output will be

reprogrammed automatically by MagCheck to original data.

4) If mode "Empty pipe" has been selected under MagCheck Function 1.1 electrode insulation

data are measured, displayed and stored.

In case of power interruption during flow meter verification e.g. by interruption of wiring, field current

supply etc. the setting of GK, pulse output and time constant must be checked and eventually

reprogrammed manually. Such an interruption is indicated by MagCheck after its restart with the

warning message: Last meter not re-programmed.

3.3

MagCheck as manual flow signal calibrator

3.3.1 Menu for manual calibration with IMoCom connection to IMoCom converters

MagCheck IMoCom connector must be connected to the IMoCom connector of the converter.

Note down all data settings and readings in a paper print of the Excel spreadsheet

“MagCheck_Verification_Listing.XLS” (see Appendix 1). After transfer of these data into this file,

error calculations and a protocol will be created automatically. Main menus must be selected

manually.