Service, Service 6.1 cleaning – KROHNE OPTISENS AAS 2000 EN User Manual

Page 28

6

SERVICE

28

OPTISENS AAS 2000

www.krohne.com

12/2008 • MA AAS 2000 R01 en

Service

6.1 Cleaning

6.1.1 Cleaning the sensor

The sensor is equipped with built-in flushing nozzles. The nozzles are used to direct the cleaning

medium (compressed air or water) via a flushing hose that is connected to the top of the sensor

housing. A solenoid valve that is wired to a relay in the converter controls the air or liquid (see

handbook OPTISENS MAC 080).

Compressed air is recommended for most applications.

Please observe the following:

•

Flush as little as possible. Flushing wears the membrane of the electrode. Excessive flushing

reduces the lifetime of the electrode.

•

Try flushing shortly twice per day (720 minutes interval, 5 seconds length). If this doesn’t keep

the membrane clean, first reduce the interval, then increase the length.

CAUTION!

Never flush if the electrode is not installed!

When the electrode is not installed, the plastic cap should be kept on the end of the sensor for

protection.

CAUTION!

The highest allowed flushing pressure is 6 bar / 87 psi. When using air, 2 bar / 29 psi is usually

sufficient.

INFORMATION!

Pay attention to the requirements for protection against backflow, according to the

EN 1717 standard for drinking water devices. If possible, use plant reuse water or effluent water

for cleaning.

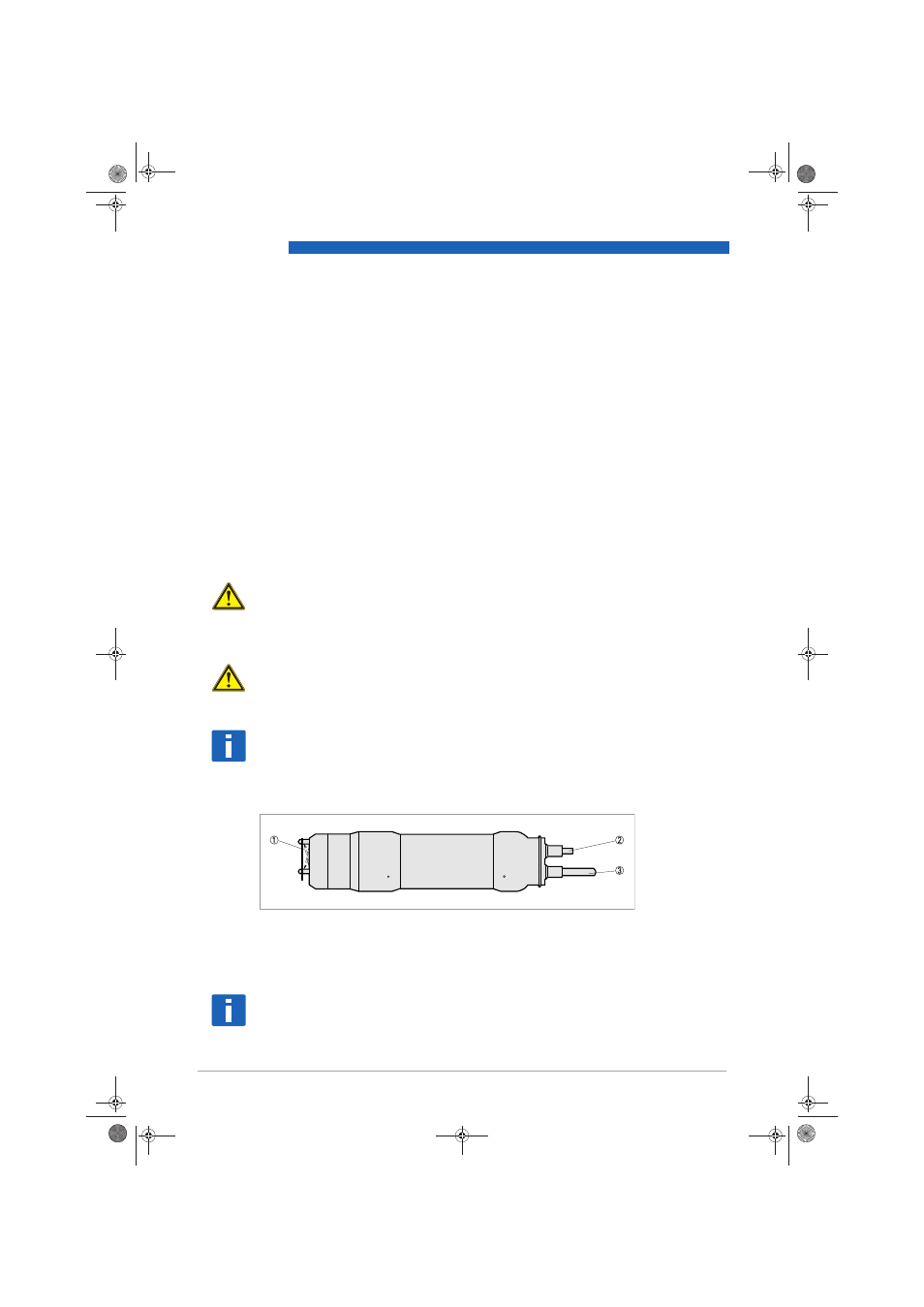

Figure 6-1:

Flushing system

1

Flushing

2

Flushung tube

3

Sensor cable

INFORMATION!

In order to clean the sensor, flushing must be activated in the Settings

Settings

Settings

Settings menu in the MAC 080

converter

.book Page 28 Monday, December 15, 2008 12:43 PM