Antifouling, Troll shield nose cone, O-ring inspection and replacement – In-Situ Level TROLL 300/500/700/BaroTROLL Operators Manual User Manual

Page 73

1-800-446-7488

73

www.in-situ.com

3. Fill the container with fresh desiccant. Replace the vent cap. Reattach to cable if

removed.

Antifouling

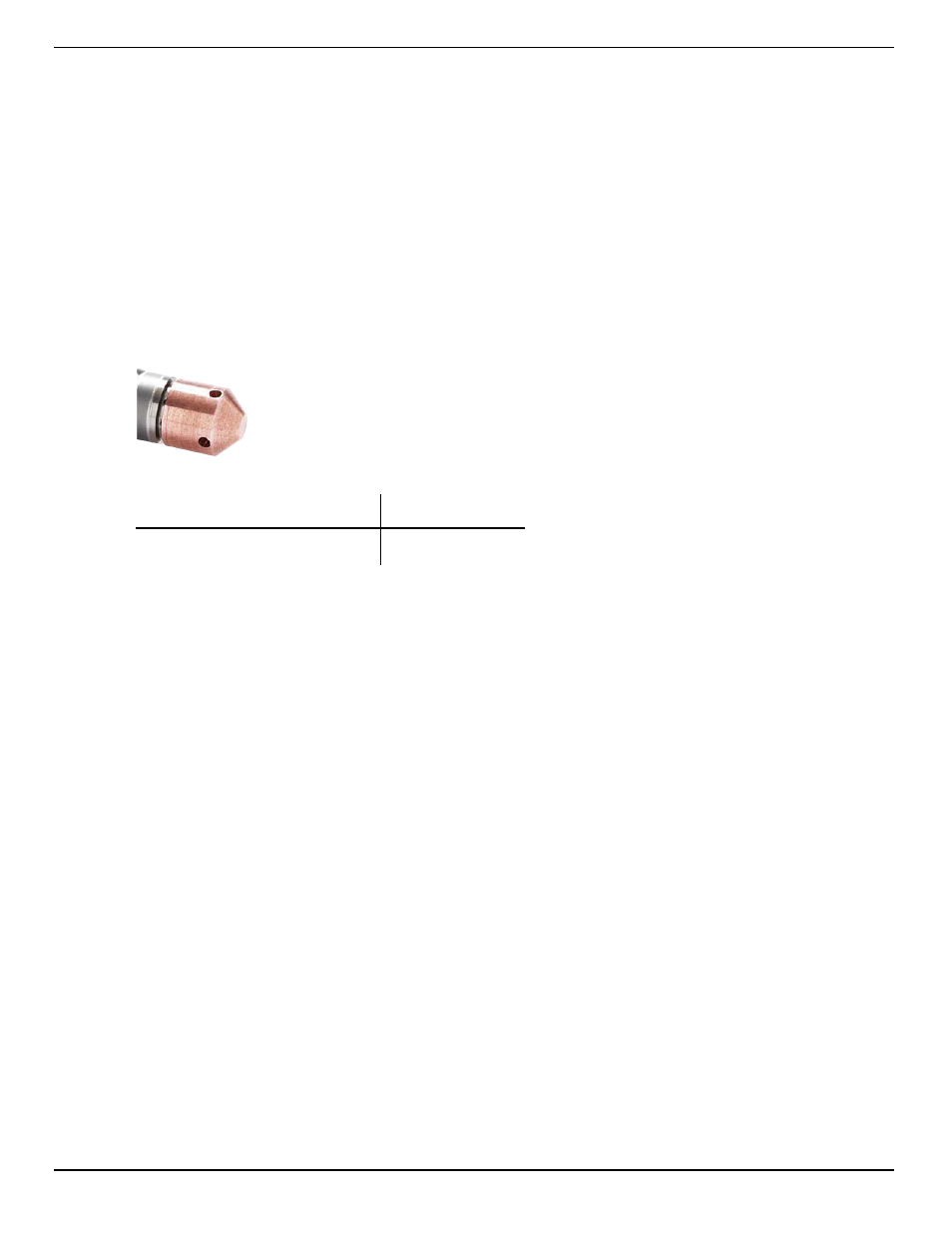

TROLL Shield Nose Cone

The copper TROLL Shield Nose Cone is designed to reduce macro- and micro-fouling

of the pressure sensor on Level TROLL and Aqua TROLL Instruments. Reduced

fouling on the sensor improves measurement accuracy and extends the length of

deployments.

For optimum performance, the TROLL Shield Nose Cone should be replaced every 12

months or sooner if site conditions are extremely harsh.

Description

Part Number

TROLL Shield Nose Cone

0081480

O-ring Inspection and Replacement

Examine O-rings for wear, dryness, discoloration, stretching, cracks, nicks, and

brittleness. Replace when any of these conditions are present. Replacing O-rings on a

regular schedule, regardless of O-ring condition, is the best way to protect against

damage.

Perform the following steps to replace an O-ring.

1. Remove and discard the damaged O-ring.

2. Use a clean, dry, soft cloth to clean the O-ring groove to remove dirt or residue.

3. Lubricate the new O-ring using high-vacuum grease.

a. Wash your hands thoroughly.

b. Apply a small amount of grease to the pad of your index finger, and

rub your index finger and thumb together to spread the grease

evenly.

c. Inspect the new O-ring and remove any debris stuck to it.

d. Rub your fingers around the O-ring until there is a thin layer of

grease on the entire O-ring.

4. Install the O-ring in the groove and remove any excess lubricant with a clean cloth.

Do not allow water or lubricant to enter the connector.