Venting – American Water Heater VG6250T100 User Manual

Page 20

20

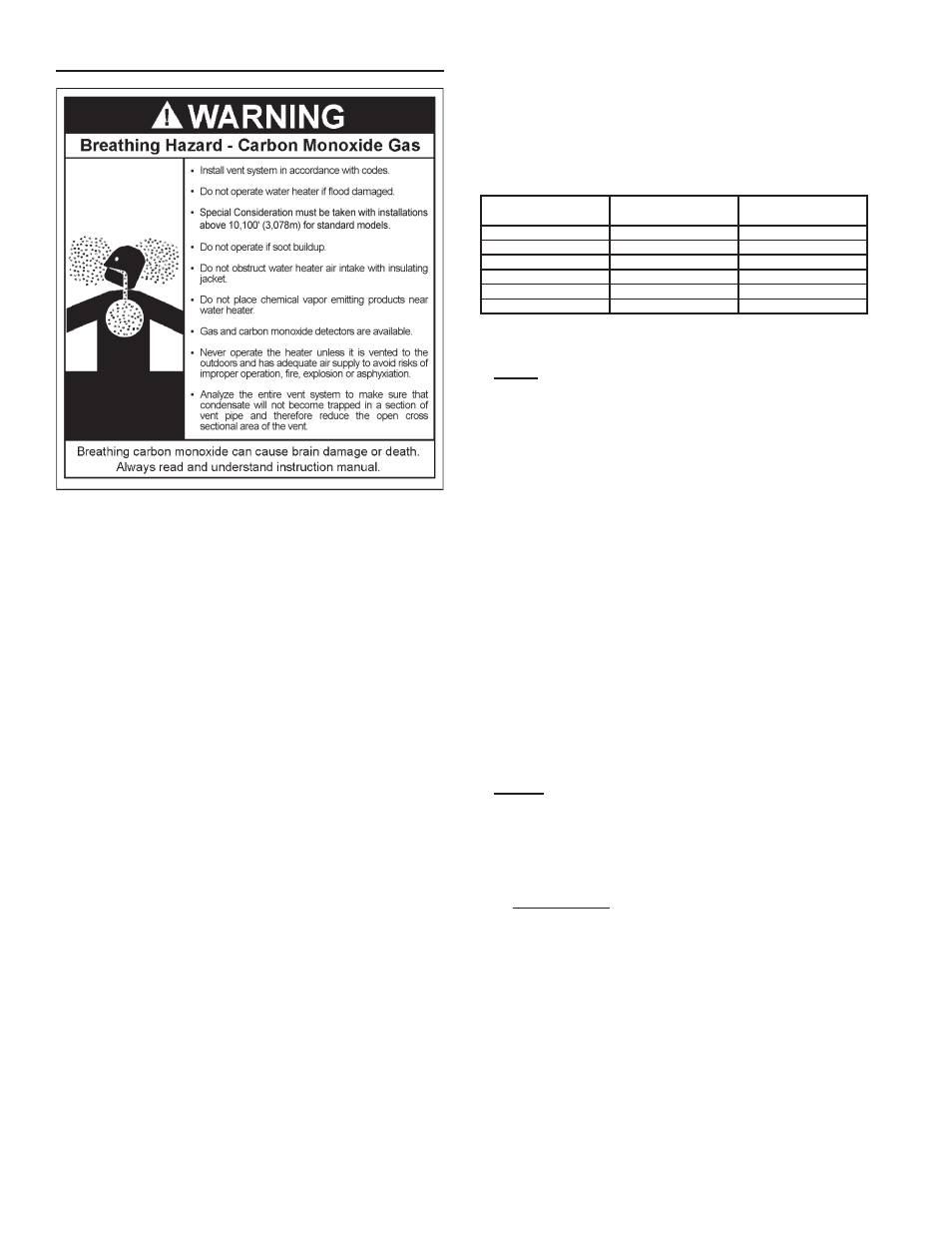

ventInG

Never operate the water heater unless it is vented to the outdoors.

The instructions in this section of the manual must be followed

to avoid choked combustion or recirculation of flue gases. Such

conditions cause sooting of the combustion chamber, burners and

flue tubes and creates a risk of asphyxiation.

For direct vent application where combustion air might be supplied

from extremely cold ambient through fresh air intake piping

system, it is recommended that a backflow preventer be installed

at the intake vent terminal close to the blower before proceeding

with installation of the rest of the fresh air intake piping. Call the

technical support phone number listed on the back cover of this

manual for more information.

vent pIpe terMInatIon

The first step is to determine where the vent pipe will terminate.

See Figures 15, 16, 17 and 18. The vent may terminate through a

sidewall as shown in Figures 15 and 16 or through the roof as shown

in Figures 17 and 18.

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current edition of the

National Fuel Gas Code, (ANSI Z223.1, 12.9.1 through 12.9.4).

See Figures 13 and 14.

Instructions on proper installation through a sidewall are provided

in Figures 15A, 15B, 15C, and 16.

Plan the vent system layout so that proper clearances are maintained

from plumbing and wiring.

Vent pipes serving power vented appliances are classified by

building codes as “vent connectors”. Required clearances from

combustible materials must be provided in accordance with

information in this manual under FACTS TO CONSIDER ABOUT

LOCATION and INSTALLING THE WATER HEATER, and with the

National Fuel Gas Code and local codes.

plannInG the vent sYsteM

Plan the route of the vent system from the exhaust elbow to the

planned location of the vent terminal.

1. Layout total vent system to use a minimum of vent pipe and elbows.

2. This water heater is capable of venting flue gases equivalent to

45’ (13.7 m) of 2” pipe, 128’ (39 m) of 3” pipe as listed in Table 5.

table 5

number of

90° elbows

2” Maximum

pipe - ft. (m)

3” Maximum

pipe - ft. (m)

1

40 (12.19)

120 (36.57)

2

35 (10.66)

115 (35.05)

3

30 (9.14)

110 (33.52)

4

25 (7.62)

105 (32)

5

20 (6.09)

100 (30.48)

6

15 (4.57)

95 (28.95)

The minimum vent length for each pipe size is one 90° plus 2’ (61

cm) of straight pipe and the appropriate termination.

note: The equivalent feet (m) of pipe listed above are

exclusive of the termination. That is, the termination, with

an installed screen, is assumed to be in the system and the

remainder of the system must not exceed the lengths discussed

above.

3. The exhaust elbow assembly is designed to accept only straight

sections of 2” pipe. To start, a minimum 2” (5.1cm) maximum

6” long of 2” pipe must be inserted and glued to the exhaust

elbow assembly if utilizing 3” vent pipe. Use the same method

with the blower inlet if a direct vent configuration is utilized.

If using 2” inch vent pipe:

A minimum of 2” (5.1cm) diameter vent pipe must be attached

to the exhaust elbow assembly. The total system cannot exceed

the lengths discussed above, where each elbow is equal to 5

equivalent feet (1.5m) of straight pipe.

If using 3” inch vent pipe:

Two inches (5.1cm) of 2” pipe must be attached to the exhaust

elbow assembly before adding a reducer to acquire the desired

pipe diameter. An appropriately sized 45 degree elbow (supplied

locally-a schedule 40 DWV) vent terminal must be obtained with

an equivalent screen (supplied in vent kit). The total system

cannot exceed the equivalent pipe lengths discussed above

where each elbow is equal to 5 feet (1.5m) of straight pipe (3”

vent pipe).

note: This unit can be vented with PVC pipe materials

(DWV ASTM-D2665 or CSA B181.2; Schedule 40, 80, 120

ASTM-D1785 or CSA B137.3; or SDR Series ASTM-D2241 or

CSA B137.3), CPVC pipe materials (CPVC41 ASTM-D2846 or

CSA B137.6; Schedule 40, 80 ASTM-F441 or CSA B137.6; or

SDR Series ASTM-F442), ABS pipe materials (Schedule 40

DWV ASTM-D2661 or CSA B181.1. The fittings, other than

the TERMINATION should be equivalent to PVC-DWV fittings

meeting ASTM D-2665 (Use CPVC fittings, ASTM F-438 for

CPVC pipe and ABS fittings, ASTM D-2661/3311 for ABS

pipe). If CPVC or ABS pipe and fittings are used, then proper

cement must be used for all joints, including joining the pipe

to Termination (PVC Material). If local codes do not allow the

use of the PVC termination when a material other than PVC is

used for venting, then an equivalent fitting of that material may

be substituted if the screen in the PVC terminal is removed and

inserted into the new fitting.